Tobacco leaf prewilting baking process for bulk curing barn

A technology of curing technology and intensive curing room, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve the problems of low smoke loading and high energy consumption in baking, and achieve increased smoke loading, improved smoke loading, and improved appearance Effects of quality and economic traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Tobacco leaves of Yunyan 87 from a certain production area in Hubei Province are baked by using the tobacco leaf pre-withering baking process in a dense curing room. The specific steps include:

[0024] (1) During the season of tobacco leaf curing, the collected fresh Yunyan 87 tobacco leaves were pre-withered on a shady hanging tobacco rack after being smoked through braiding rods or tobacco clips, resulting in 14.6% water loss of the lower tobacco leaves, The tobacco leaves are obviously soft; the middle tobacco leaves lose water by 12.1%, and the tobacco leaves are soft; the upper tobacco leaves lose water by 10.8%, and the tobacco leaves are soft;

[0025] (2) Move the Yunyan 87 tobacco leaves that meet the dehydration requirements after the pre-withering treatment in step 1 into the intensive curing barn, ignite the fire after being placed, and increase the temperature at a rate of 1 °C per hour to 38 °C and stabilize the temperature. The wet bulb temper...

Embodiment 2

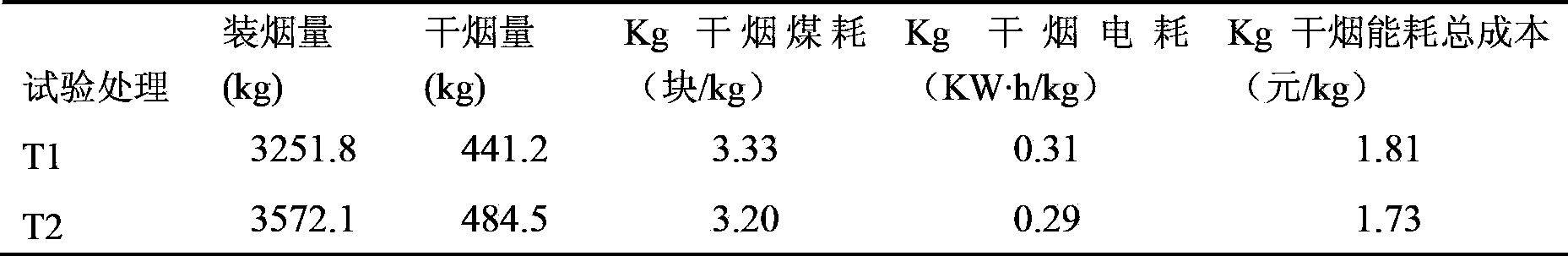

[0029] Example 2 For the central tobacco leaves of Yunyan 87 in a certain production area in Hubei Province, the following two curing processes were adopted: T1 adopts three-stage curing (the existing conventional process), and T2 adopts the pre-withering intensive curing process (this paper) The process described in the invention), the energy consumption statistics of the roasting are carried out, and the economic properties, appearance quality, chemical composition and sensory quality of the roasted tobacco leaves are compared. The results are shown in Table 1-5.

[0030] Table 1 Comparison of energy consumption of different baking processes

[0031]

[0032] Note: Coal consumption is calculated in briquettes, 0.45 yuan per piece; electricity price is 0.99 yuan / KW·h.

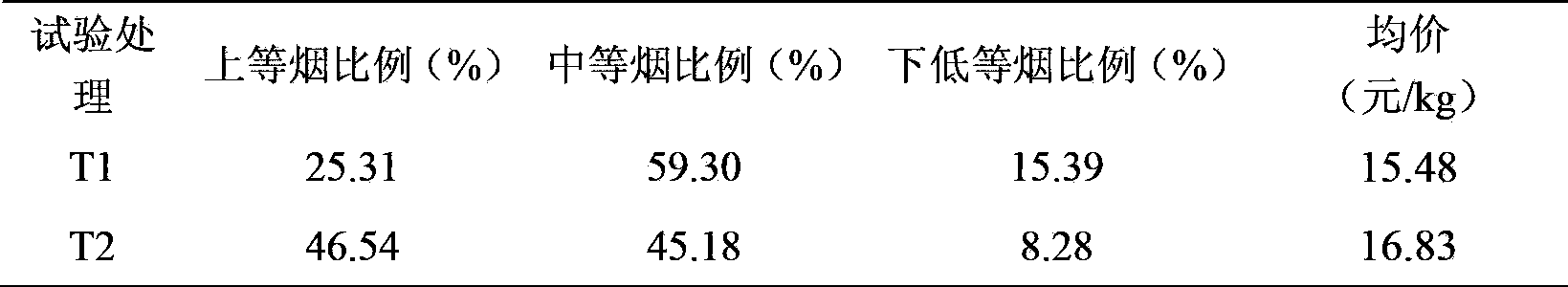

[0033] Table 2 Economic properties of tobacco leaves after curing

[0034]

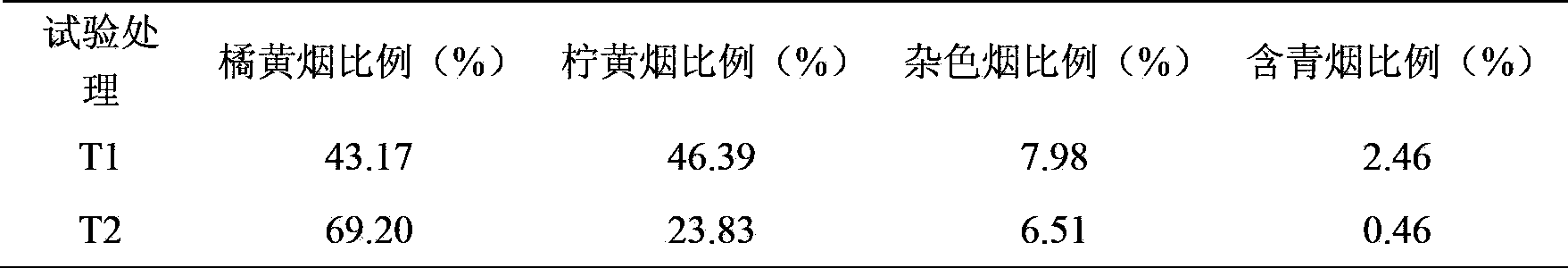

[0035] Table 3 Color distribution of tobacco leaves after curing

[0036]

[0037] Table 4 Chemical composition of cured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com