Beat transmission equipment of production line

A transmission equipment and production line technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large vibration and friction of mechanical transmission, high noise of transmission equipment, and impact on product quality, so as to improve productivity and reduce vibration , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

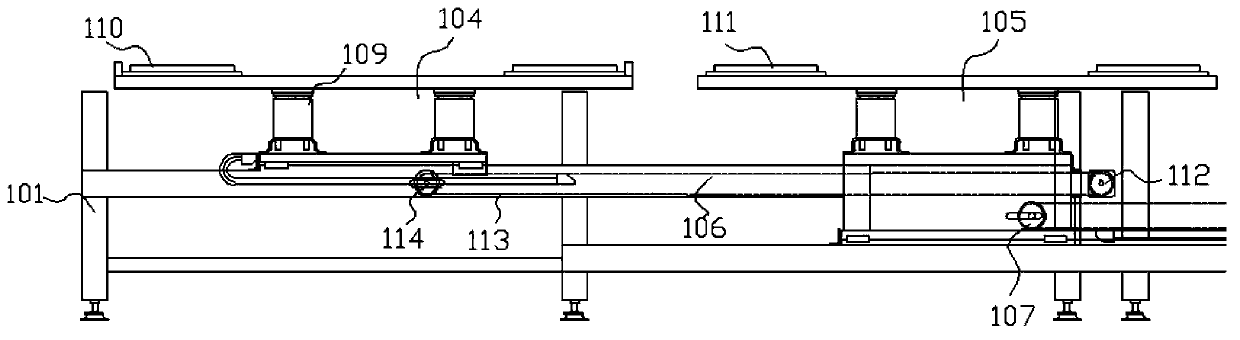

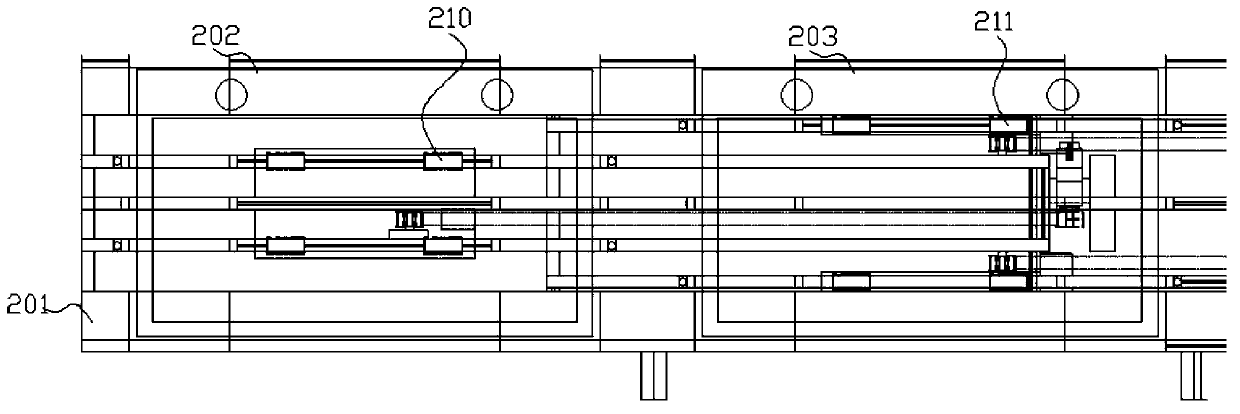

[0020] Such as figure 1 Or as shown in 2, a production line beat transmission equipment includes a workbench group, the workbench group includes a frame 101, a first workbench 202 and a second workbench 203, the frame 101 is used to support the entire equipment, Simultaneously the horizontal plane of the upper end place of frame 101 is exactly the working surface of production line; The first workbench 202 and the second workbench 203 are to be used to realize a processing position that product is transported to this position to carry out processing operation; The first workbench 202 comprises the 2nd workbench A lifting device 104 and a first transmission device 106, the first lifting device 104 reciprocates between the first workbench 202 and the second workbench 203, the first transmission device 106 is for the first lifting device 104 from the first The position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com