Multi-spiral high-precision quantitative feeding device

A quantitative feeding device and screw feeding technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of affecting the quality of water treatment, dry powder drug bridge blockage, inaccurate quantity, etc., to achieve quantitative delivery, Avoid uneven cutting and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

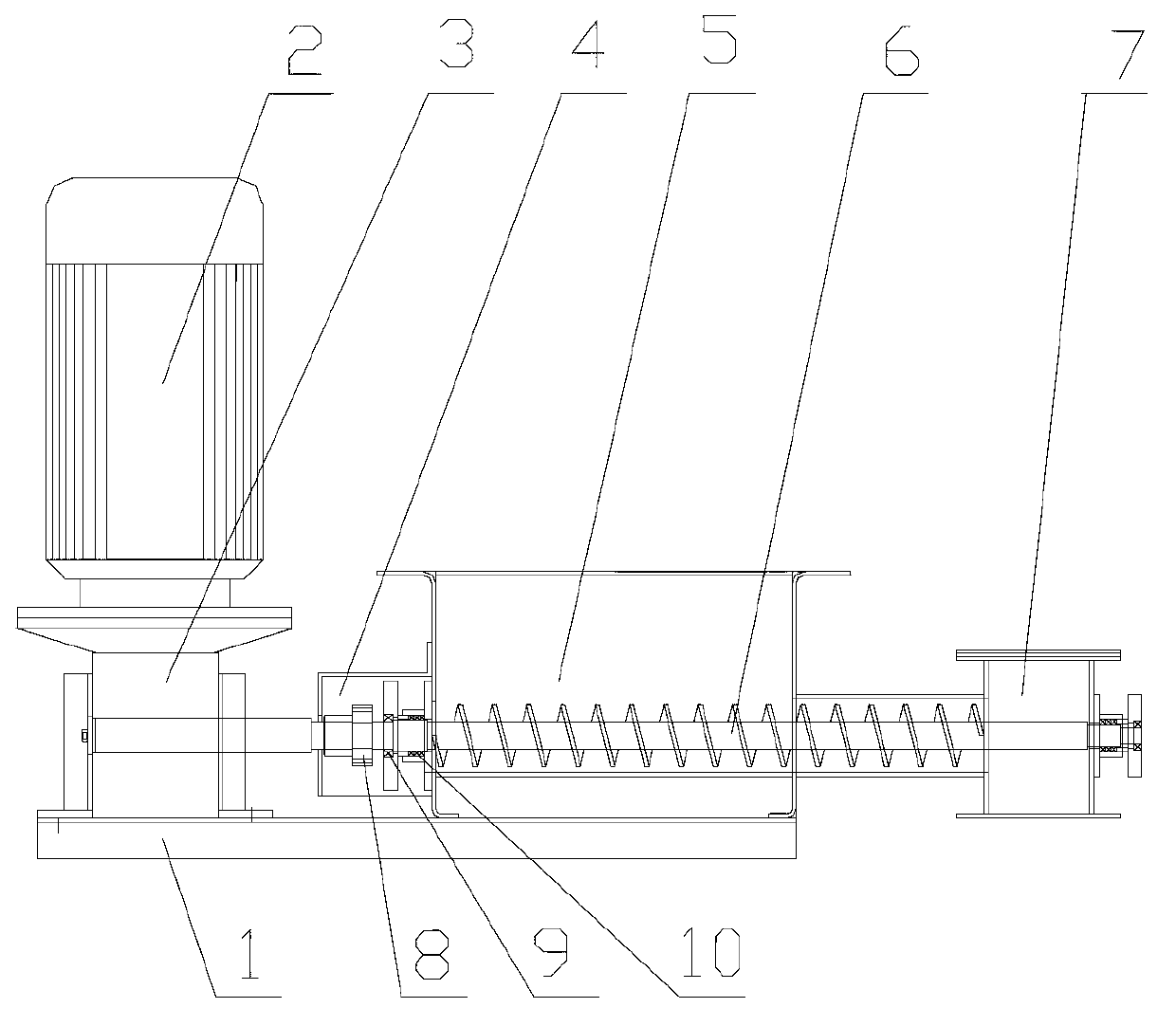

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

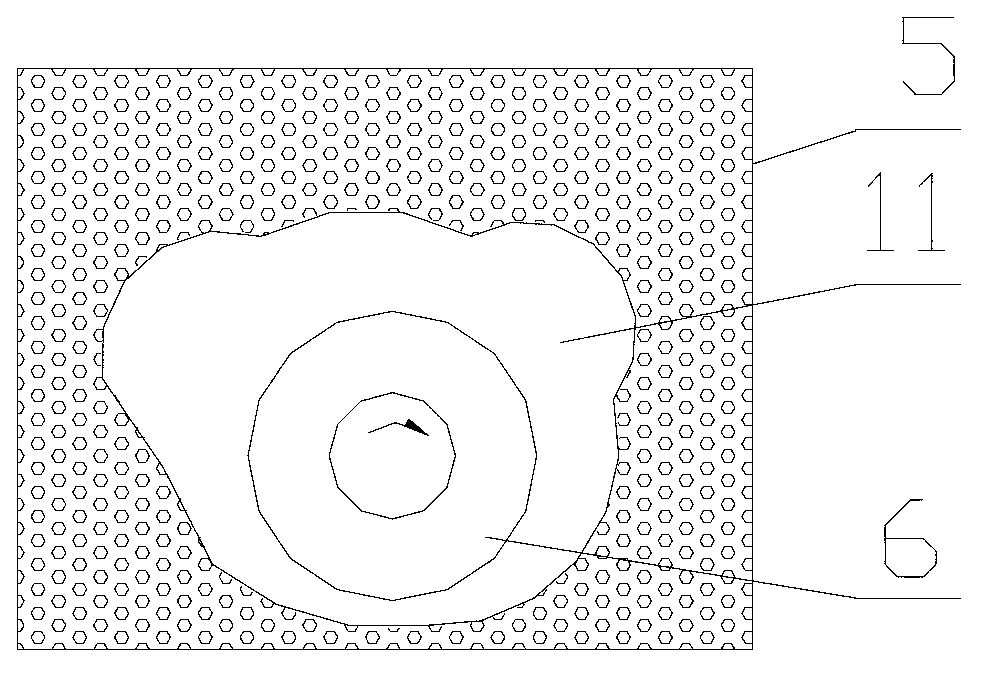

[0011] figure 1 Shows the case where the quantitative delivery unit consists of one or two screw rods. When one or two screw rods 6 rotate in the feeder box 5, since the screw rods 6 cannot clean the powder sticking to the screw blades during the working process, it is easy for the dry powder agent to bridge to form the silo cavity 11. The phenomenon is also called "shelf", which leads to problems such as uneven cutting or even no cutting. The quality of water treatment will be seriously affected due to the inaccurate quantity of the dry powder agent.

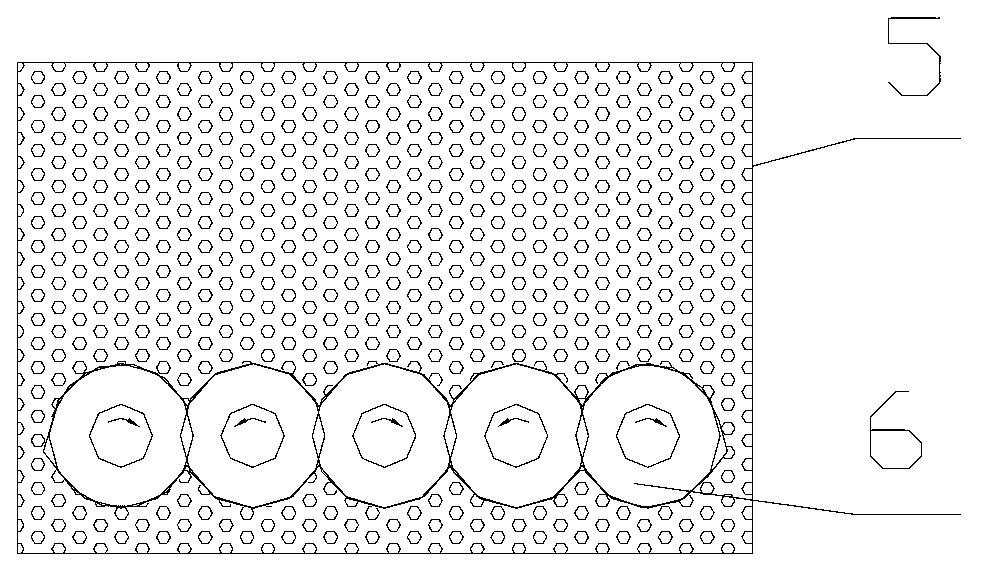

[0012] figure 2 It is a schematic diagram of the multi-screw high-precision quantitative feeding device of the present invention. The screw blades of the screw feeding mechanism have the same helix angle and blade diameter, and the rotation direction of the adjacent screw rods 6 is opposite, and a part is embedded in each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com