A rare earth uniformly doped optical fiber preform core rod and its preparation method

An optical fiber preform and uniform doping technology, applied in the field of optical fiber manufacturing, can solve the problem of uneven doping of preforms, fluorine-doped cladding outer cladding technology and rare-earth-doped optical fiber technology have not been realized, and can not meet the requirements of one-rod multi-fiber design and Optical fiber implementation technology requirements and other issues, to achieve the effects of flexible selection, easy control of concentration allocation, and low background absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

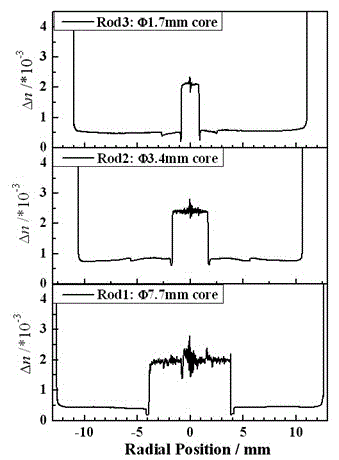

[0026] Mandrel embodiment 1: Add nanoporous SiO2 powder with a particle size of 10 to 200 nm into the chloride aqueous solution of rare earth and co-doped ions, the ratio of the molar concentration of dopant ions Al3+ to the molar concentration of rare earth ions Yb3+ in the solution is 5 to 6, and then Adjust the pH value of the solution to 10-11 with ammonia water, stir continuously to form a suspension; then perform high-speed centrifugation to separate solid particles and liquids, then dry, dehydrate, and granulate to form ion-adsorbed SiO2 particles; After static pressure molding, Cl2 dehydration and purification are carried out; then in the atmosphere furnace, high-temperature sintering is dense, the sintering temperature is 1500-1600 °C, and the sintering time is 5-20 hours; after that, the surface processing and chemical cleaning are carried out to obtain Cylindrical rare earth doped silicon oxide core rod; finally, a thin layer of SiO2 without rare earth ion doping i...

Embodiment 2

[0027] Mandrel embodiment 2: The nanoporous SiO2 powder with a particle size of 10-200 nm is added to the chloride ethanol solution of rare earth and co-doped ions. The ratio of the molar concentration of dopant ions Al3+ in the solution to the sum of the molar concentrations of rare earth ions Yb3+ and Er3+ is 9 to 12, then adjust the pH value of the solution to 7 to 9 with ammonia water, and continue to stir to form a suspension; then perform high-speed centrifugation to separate solid particles and liquids, then dry, dehydrate, and granulate to form ion-adsorbed SiO2 particles; ion adsorption After the SiO2 particles are formed by isostatic pressing, they are dehydrated and purified by Cl2; then in the atmosphere furnace, they are sintered and dense at high temperature, the sintering temperature is 1200-1600 °C, and the sintering time is 2-10 hours; after that, the surface processing is carried out. and chemical cleaning to obtain a cylindrical rare-earth-doped silicon oxi...

Embodiment 3

[0028] Mandrel embodiment 3: The nanoporous SiO2 powder with a particle size of 10-200 nm is added to the hydrogen phosphate aqueous solution of rare earth and co-doped ions, and the ratio of the sum of the molar concentrations of the dopant ions Al3+ and PO33- to the molar concentration of the rare earth ions Er3+ Adjust the pH value of the solution to 25-30 to 7-8, stir continuously to form a suspension; then perform high-speed centrifugation to separate solid particles and liquids, then dry, dehydrate, and granulate to form ion-adsorbed SiO2 particles; ion-adsorbed SiO2 particles After isostatic pressing, Cl2 dehydration and purification are carried out; then in the atmosphere furnace, high-temperature sintering is dense, the sintering temperature is 1000-1400 °C, and the sintering time is 1-8 hours; after that, the surface processing and chemical cleaning are carried out , to obtain a cylindrical rare-earth-doped silicon oxide core rod; finally, a thin layer of SiO2 witho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com