Preparation method and device of high-conductivity carbon nanotube film

A carbon nanotube film and carbon nanotube technology, applied in the field of material science, can solve the problems of limited catalytic cracking reaction conditions, high temperature at the film forming place, difficulty in obtaining carbon nanotube film, etc., and achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

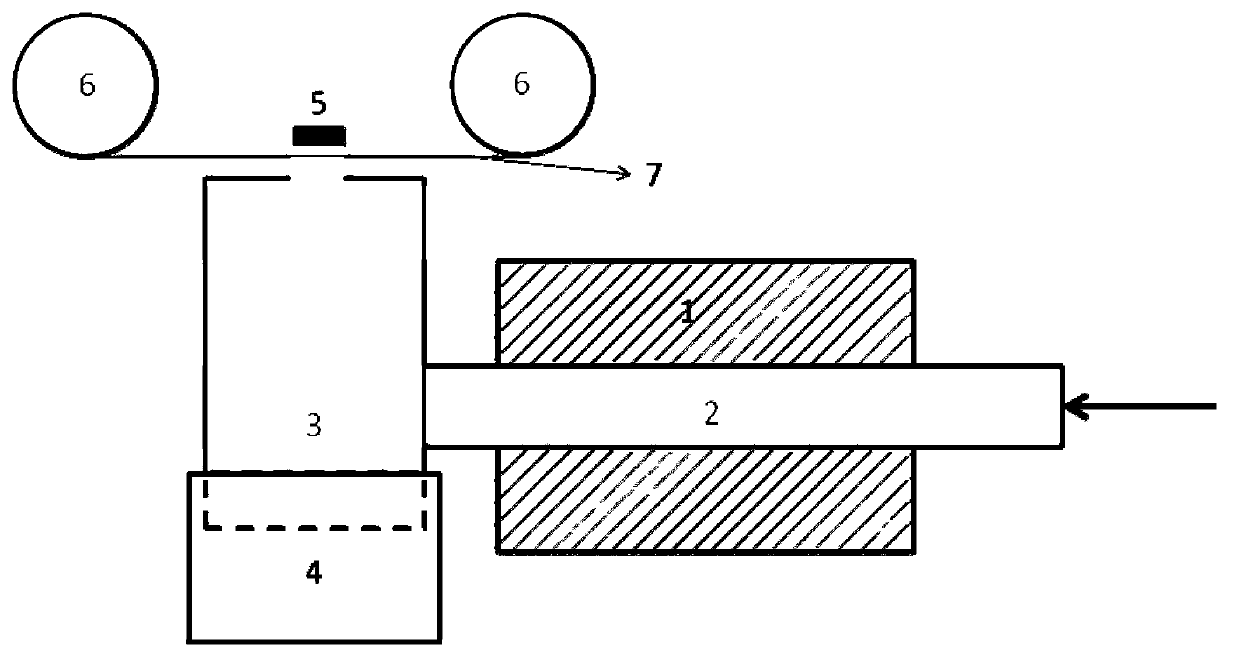

[0036] One aspect of the present invention relates to a method for preparing a highly conductive carbon nanotube film, including: using a floating catalytic cracking method to prepare a carbon nanotube aerosol at a temperature as high as 1250-1600°C, and preferably using a carrier gas The nanotube aerosol is introduced into the closed cavity, and a substrate is arranged at a position corresponding to the slit opened in the closed cavity, and a directional magnetic field is used to induce the carbon nanotubes in the closed cavity to pass through the narrow And oriented deposition onto the substrate to form a highly conductive carbon nanotube film.

[0037] When the light transmittance of the substrate is about 92%, the light transmittance of the highly conductive carbon nanotube film can be as high as 88%, and the surface resistance can be as low as 100Ω / □.

[0038] Further, to prevent the carbon nanotube aerosol from agglomerating, one or more air ultrasonic generators can also be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com