Actuating tool bar

A tool and bar technology, which is applied in the field of weaving tool bar, can solve the problems of limiting the working speed of weaving tool bar, and achieve the effect of favorable mass distribution, favorable moment of inertia, and expanded possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

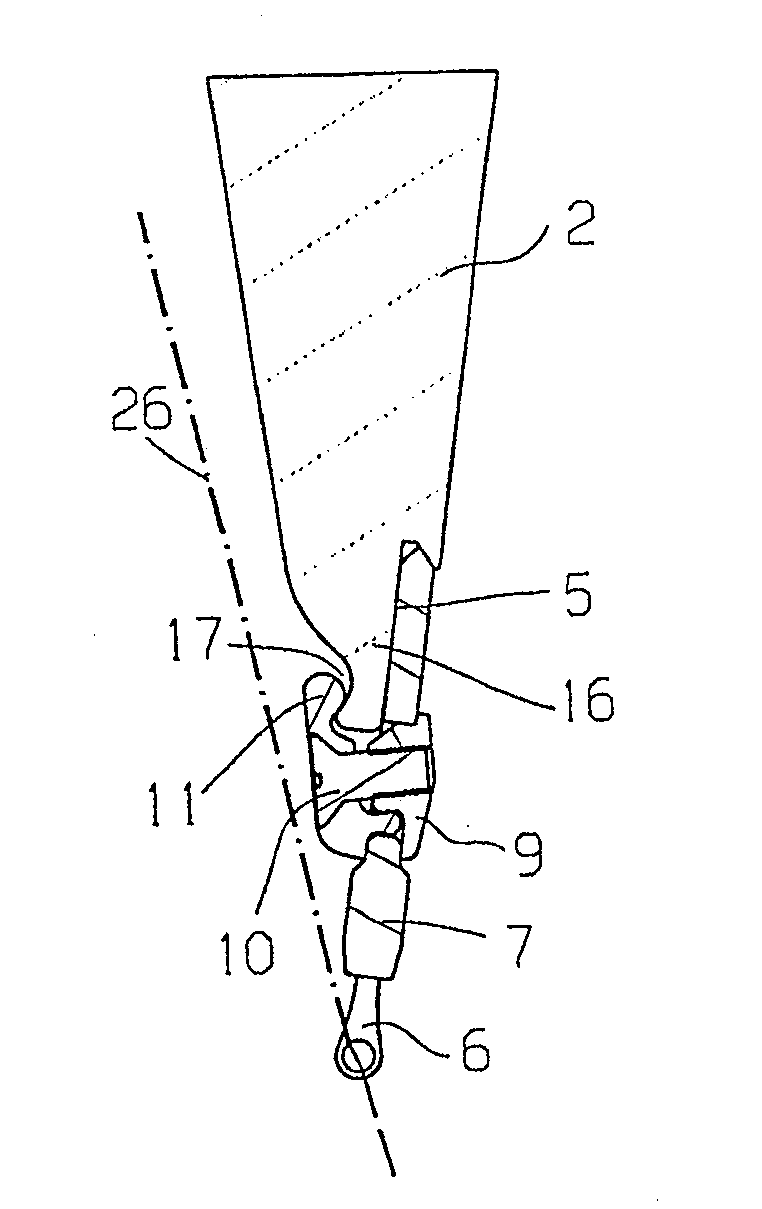

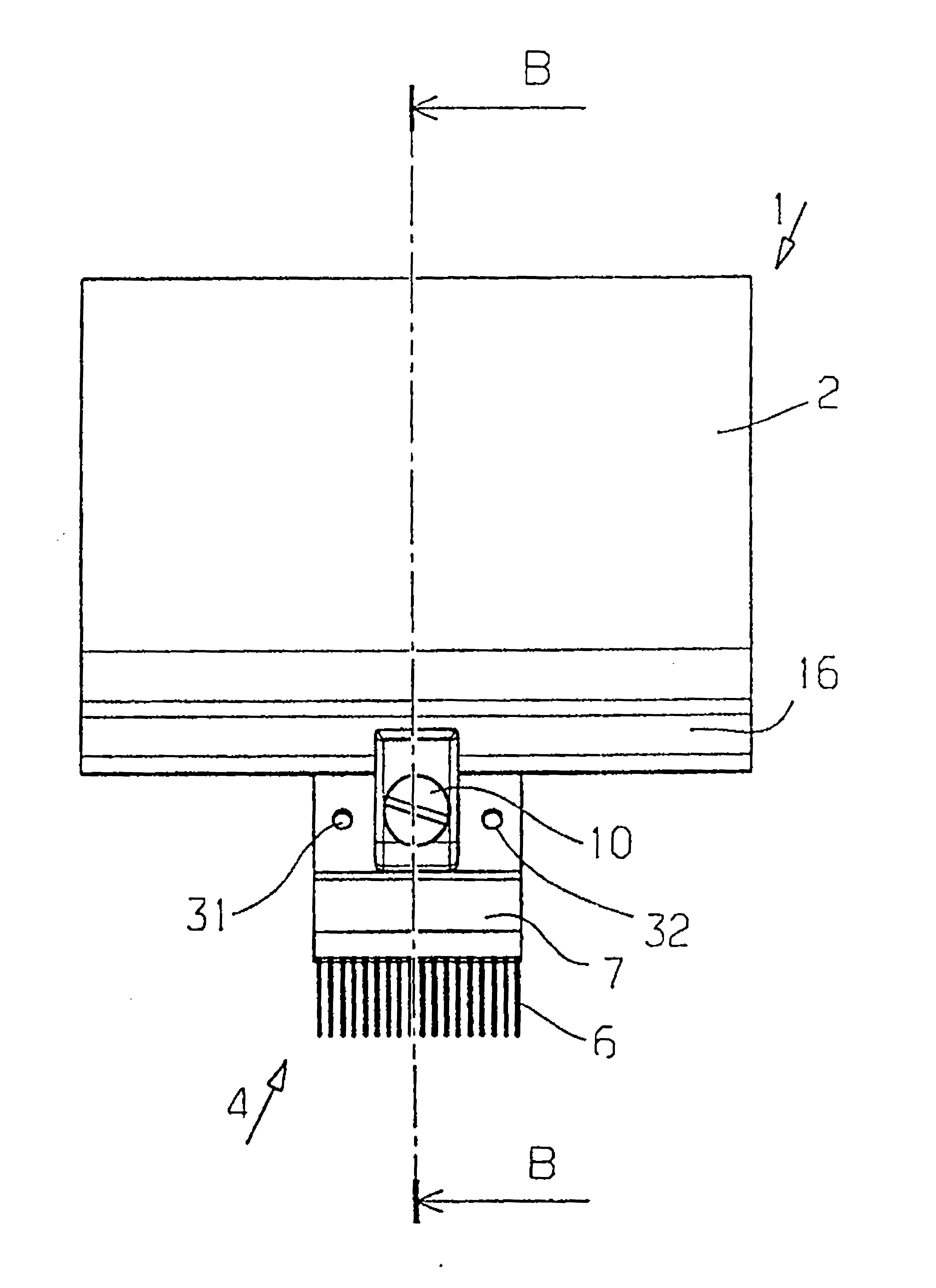

[0030] exist figure 1 The knitting tool bar 1 shown schematically in FIG. 1 is in the present case designed as a thread guide bar and has a main body 2 with an edge 3 . The braiding tool device 4 is fixed on the main body 2 . For this purpose, the main body 2 has a fastening area with an abutment surface 5, by figure 2 It can be seen that the braiding tool device 4 can be installed on the abutment surface.

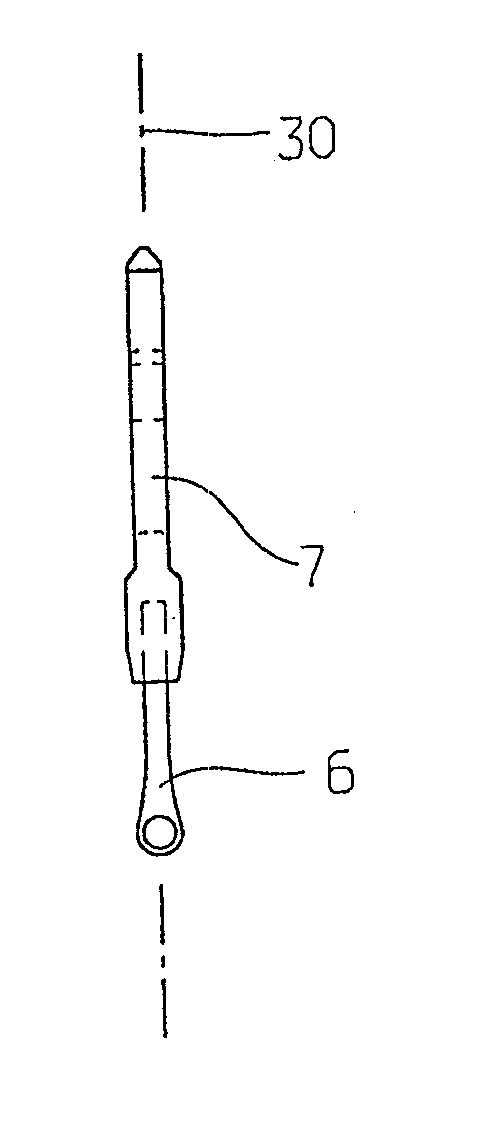

[0031] The knitting tool device 4 has a plurality of knitting tools 6 , which in the present case are designed as eye needles and can thus be used as thread guide needles. The weaving tool 6 is collected in a weaving tool holder 7 . The braiding tool support 7 can generally also be referred to as a "base".

[0032] The braiding tool holder 7 has a through hole 8 into which an insert 9 is inserted from one side. A fastening screw 10 , which can also be referred to as a “fastener”, is guided through the insert 9 . The fastening bolt 10 is screwed into a clamping eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com