Upright quilter movement feeding device

A quilting machine, vertical technology, applied in sewing machine components, cloth feeding mechanisms, sewing equipment and other directions, can solve the problems of difficulty in obtaining quilting patterns, low processing accuracy, high production costs, etc. Assembly time, footprint reduction, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing:

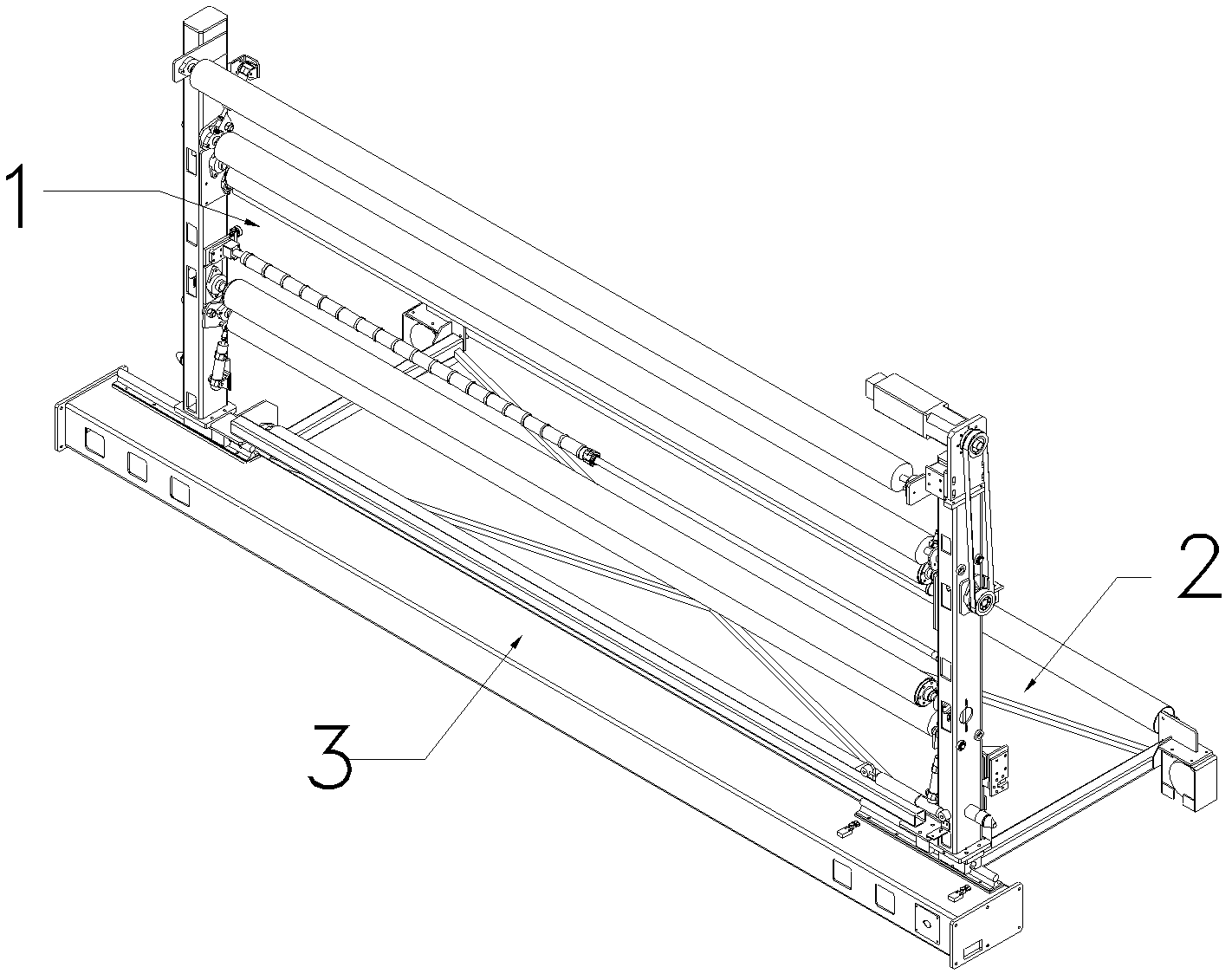

[0018] attached figure 1 It is the general assembly drawing of the mobile feeding device of the vertical quilting machine, mainly including the vertical cloth transfer assembly 1, the cloth horizontal transfer assembly 2 and the lower beam assembly 3, the cloth vertical transfer assembly 1 and the cloth horizontal transfer assembly 2 are connected, and additionally respectively connected to the lower beam assembly 3 .

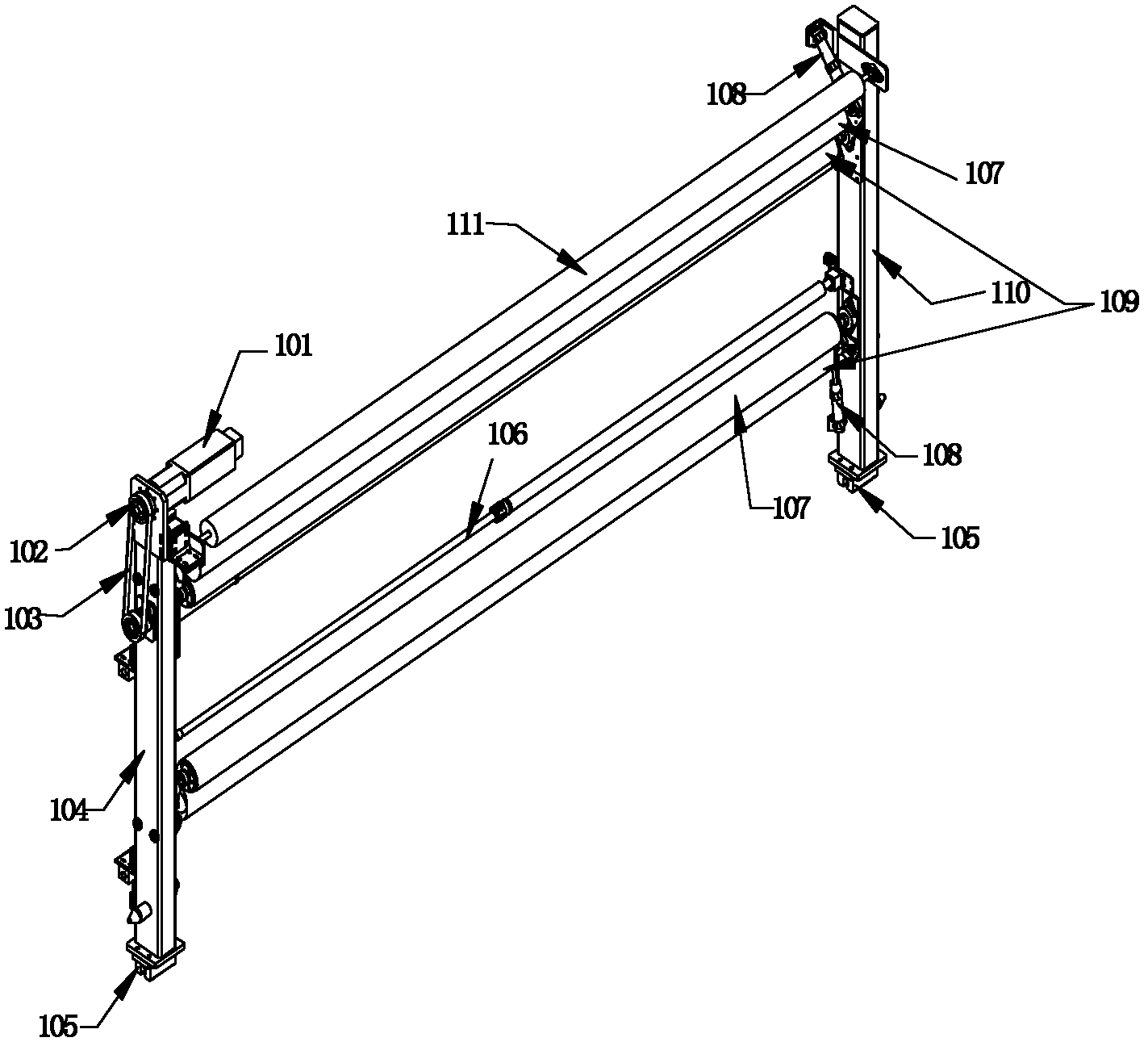

[0019] attached figure 2 It is a structural diagram of the cloth vertical transmission assembly in the mobile feeding device of the vertical quilting machine. The cloth vertical transmission assembly 1 includes a left column 104, a right column 110, a reel 106, a pressure roller 107, a driving roller shaft 109, and a guide roller 111, cylinder 108, belt 103, pulley 102, motor 101, vertical transmission assembly slide block 105. The bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com