A drill-expansion combination drill bit

A combination drill bit and drill reaming technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., can solve the problems affecting the construction progress and project quality, and achieve the effects of short construction period, increased cross-sectional area and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

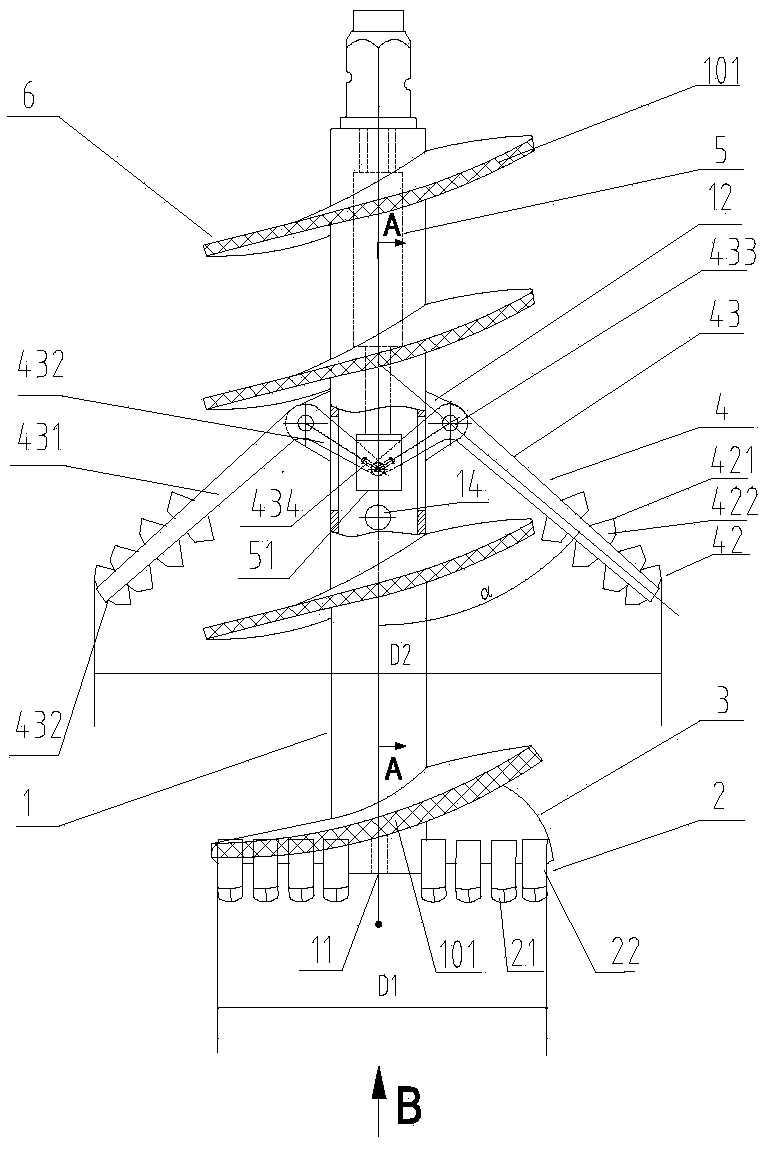

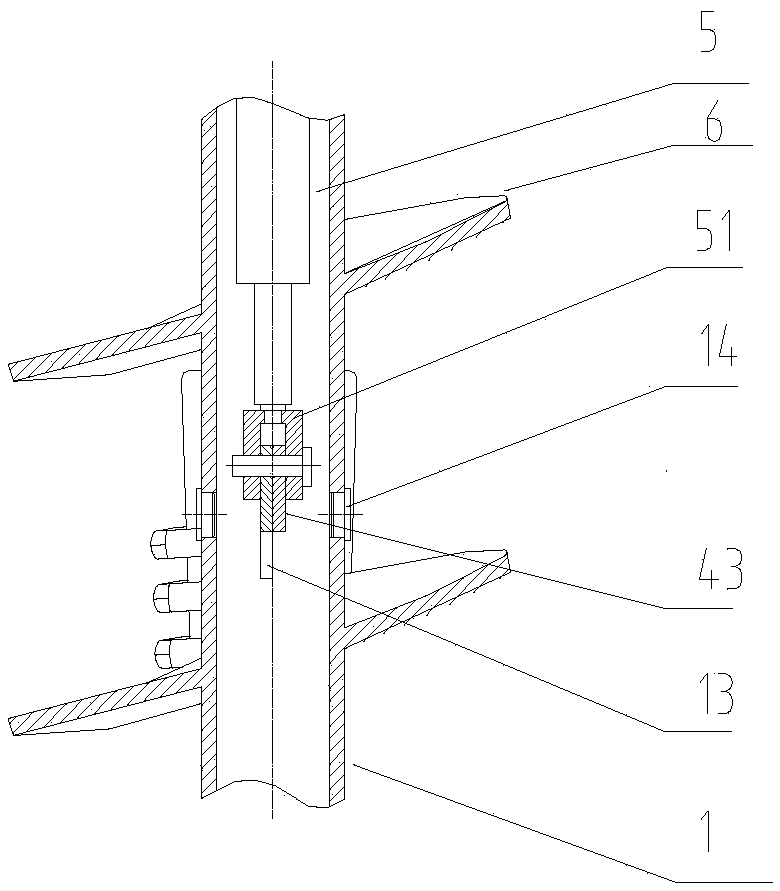

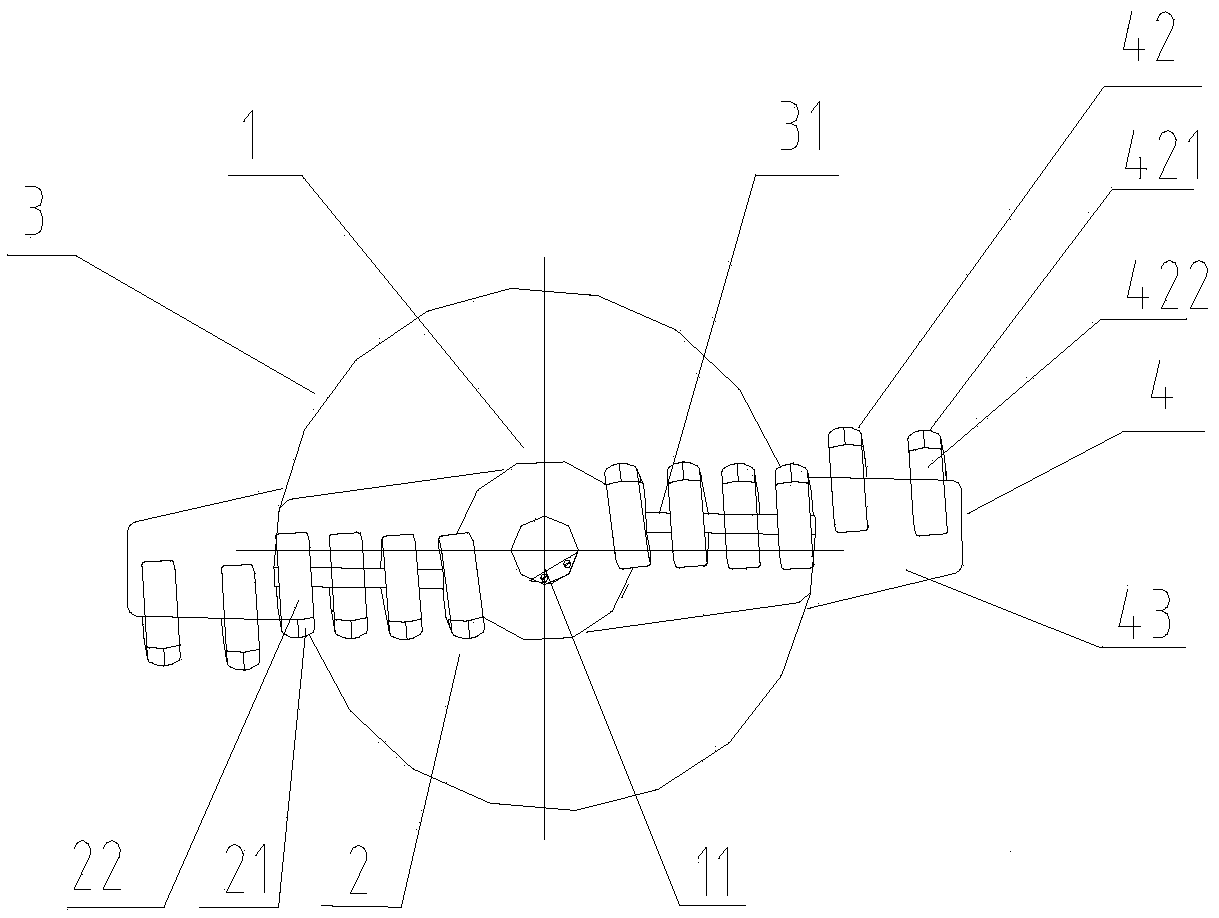

[0028] like figure 1 , figure 2 and image 3 Shown, a kind of drilling-expanding combination drill bit comprises: hollow rod body 1, comprises grouting channel 11, pin seat 12, straight groove 13 and installation screw plug 14; Multiple cutter body 2, each cutter body 2 comprises a cutter head 21 and A knife handle 22; Expanding knife bar 4, comprise fork 43 and a plurality of expanding knife bodies 42 installed on the fork 43, each expanding knife body 42 includes an expanding knife head 421 and an expanding knife handle 422, fork 43 includes Long arm 431, short arm 432, pin hole 433 and waist-shaped elongated groove 434; Lower blade 3; Oil cylinder 5 and upper blade 6 that are fixed in the cavity of hollow rod body 1; It is characterized in that: described lower blade 3 has 2- 4, uniformly distributed on the outer peripheral surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com