Diaphragm plate type idle speed control valve

A technology of idle speed control valve and diaphragm plate, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of unstable idle speed, bearing slippage, aging of rotating core, unstable idle speed condition, etc., to increase riding comfort. performance, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

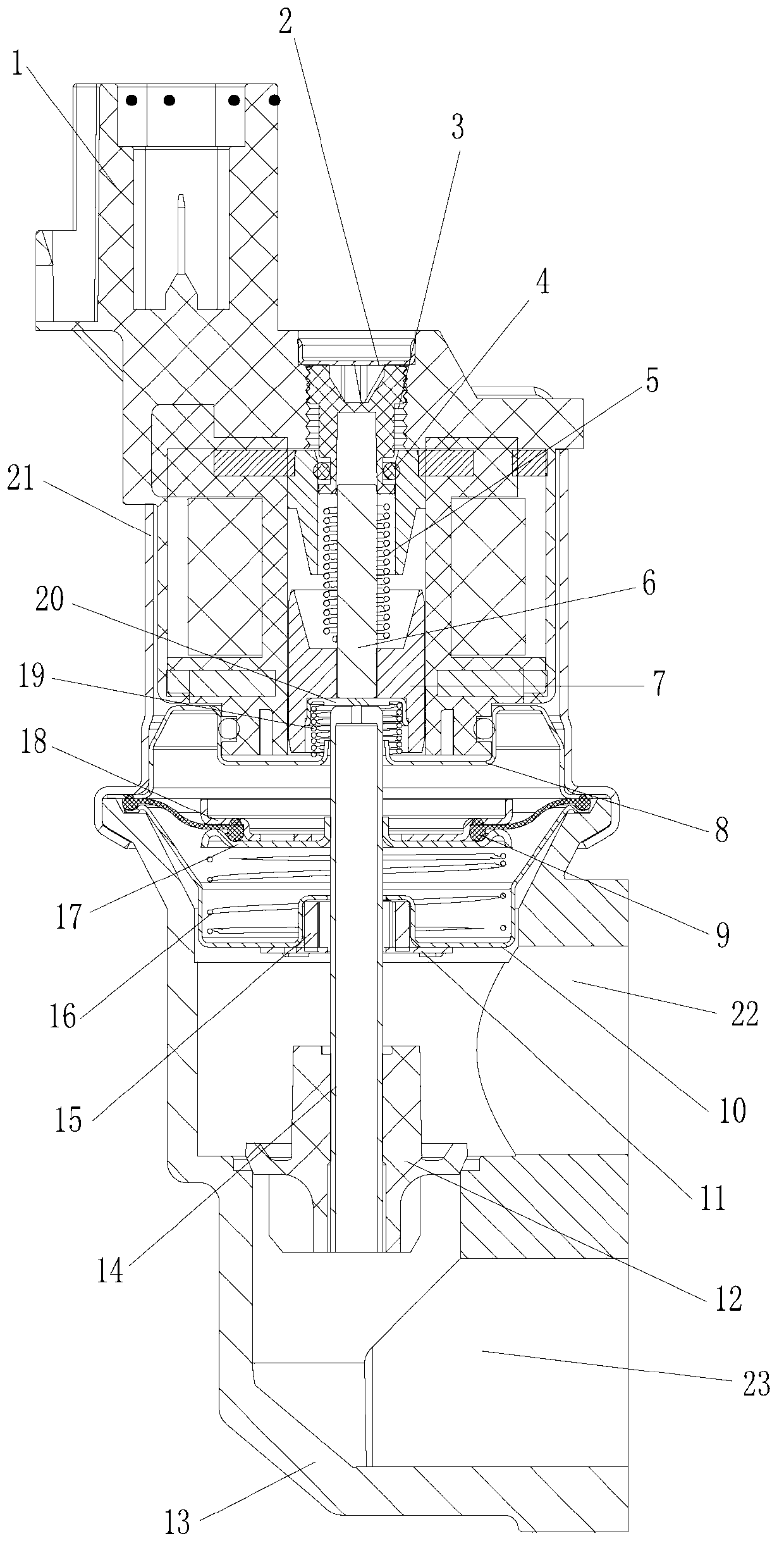

[0019] Please also refer to figure 1 , as shown in the figure, a diaphragm plate type idle speed control valve includes a valve body, the valve body includes a coil package assembly, and a valve seat 13 installed in cooperation with the coil package assembly. The valve seat 13 is provided with upper and lower settings The air inlet 22 and the air outlet 23, the coil package assembly further includes a coil package assembly 1 cooperating with the installation, a sleeve 21 riveted with the coil package assembly 1, a piston assembly, a third compression spring 19 and The upper cover plate 8, the piston assembly, the third compression spring 19 and the upper cover plate 8 are sequentially installed in the coil package assembly 1, and the piston assembly further includes a valve stem 6, a piston 7 cooperating with the valve stem 6, and a press-in The sealing cover 20 in the piston 7, the valve body further includes a diaphragm plate assembly, the diaphragm plate assembly includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com