Crop dryer oil tank with second level filtration structure

A grain dryer and secondary filtration technology, applied in the direction of dryers, drying, heating devices, etc., can solve the problems of inconvenience, insufficient fuel filtration, and unintuitive observation, so as to improve the filtering effect and intuitive observation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

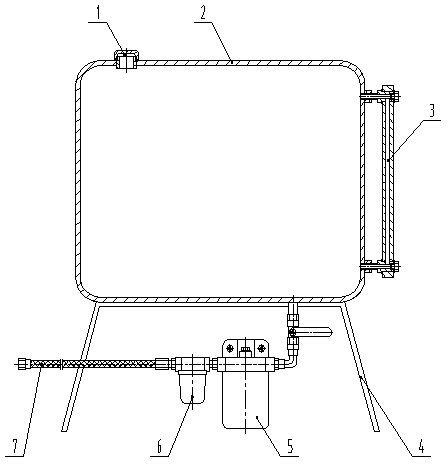

[0012] The grain dryer oil tank with a secondary filter structure shown in the accompanying drawings includes an oil tank body 2, a fuel filler port 1, a coarse filter 5, an output pipe 7, and an oil mark 3. The present invention includes the coarse filter 5, the output pipe The fine filter 6 is connected in series between 7, and the number of filter meshes used in the fine filter 6 is more than that of the coarse filter 5; the oil mark 3 is set on the side of the oil tank, which is an upright transparent tubular oil In this embodiment, scale lines are provided on the upright transparent tube, so that it is intuitive and convenient to observe the amount of oil in the fuel tank.

[0013] In the present invention, fine filtration is added after coarse filtration, the filtration effect is remarkably improved, and cleaner fuel oil is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap