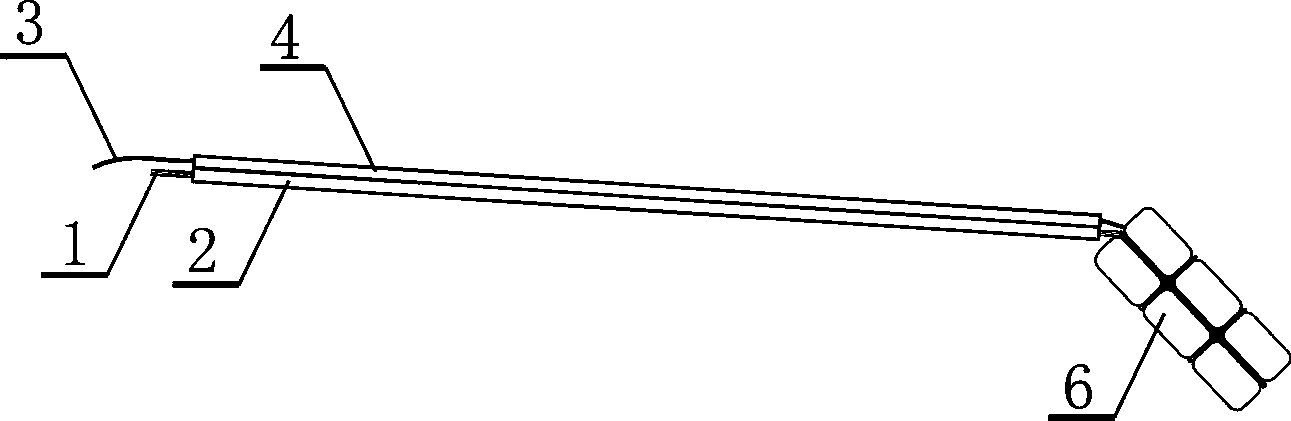

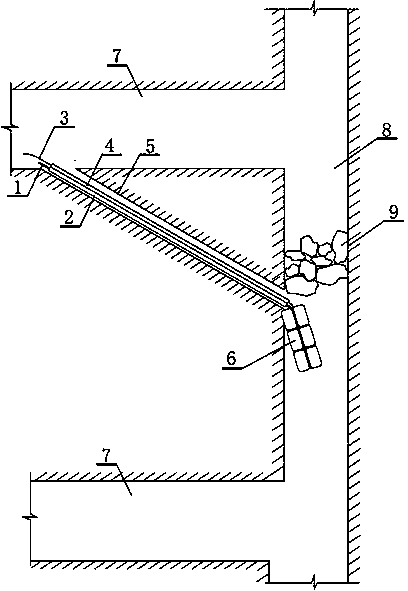

Method for effectively removing ore-pass blockage and blockage removal device

A well-sliding, high-efficiency technology, applied in blasting and other directions, can solve problems such as high safety risks, low success rate, and difficult construction, and achieve the effects of ensuring construction safety, simple structure, and simple and practical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] The suitable chute 7 described in the A step refers to two chute 7, one chute 7 is at the high position of the blocking point, and another chute 7 is at the low position of the blocking point, and is connected with the chute 8. The chute 8 naturally falls or slides from top to bottom, and mineral materials are usually piled up above the blocking point. It is impossible to accurately determine the position of the blocking point from the high position of the blocking point. Pass, so that the worker detects the blocked point position, in addition, explosives are fixed on the traction rope 1 and also need this chute joint 7. It is very important to be able to accurately determine the position of the blocking point, and there are many methods to choose, such as using the positioning system to determine the coordinate position and altitude position difference of the drilling point and the blocking point, so that the drilling direction can be easily calculated. Also can select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com