Direct detection system for surface-shape errors in full-aperture optical aspheric surfaces

A surface shape error and detection system technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of long measurement period, high cost, large amount of data, etc., achieve shortened detection preparation cycle, reduce detection cost, and measure wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

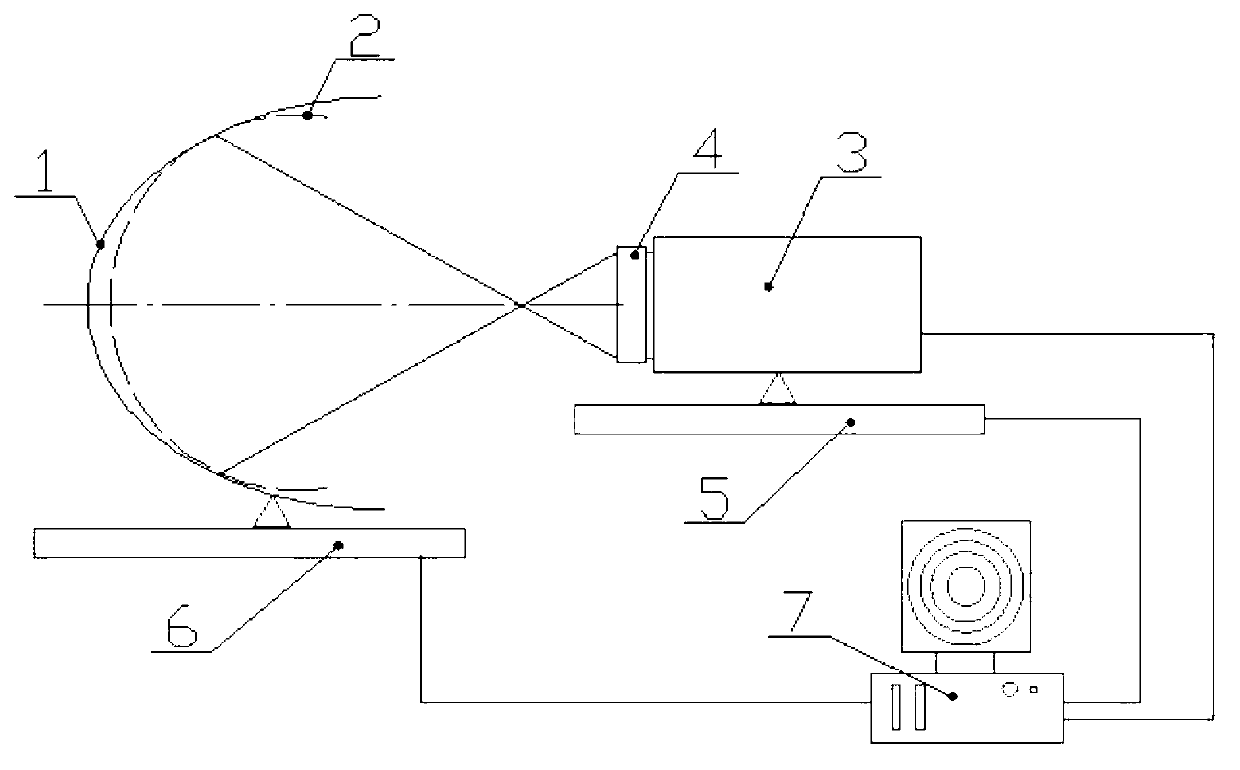

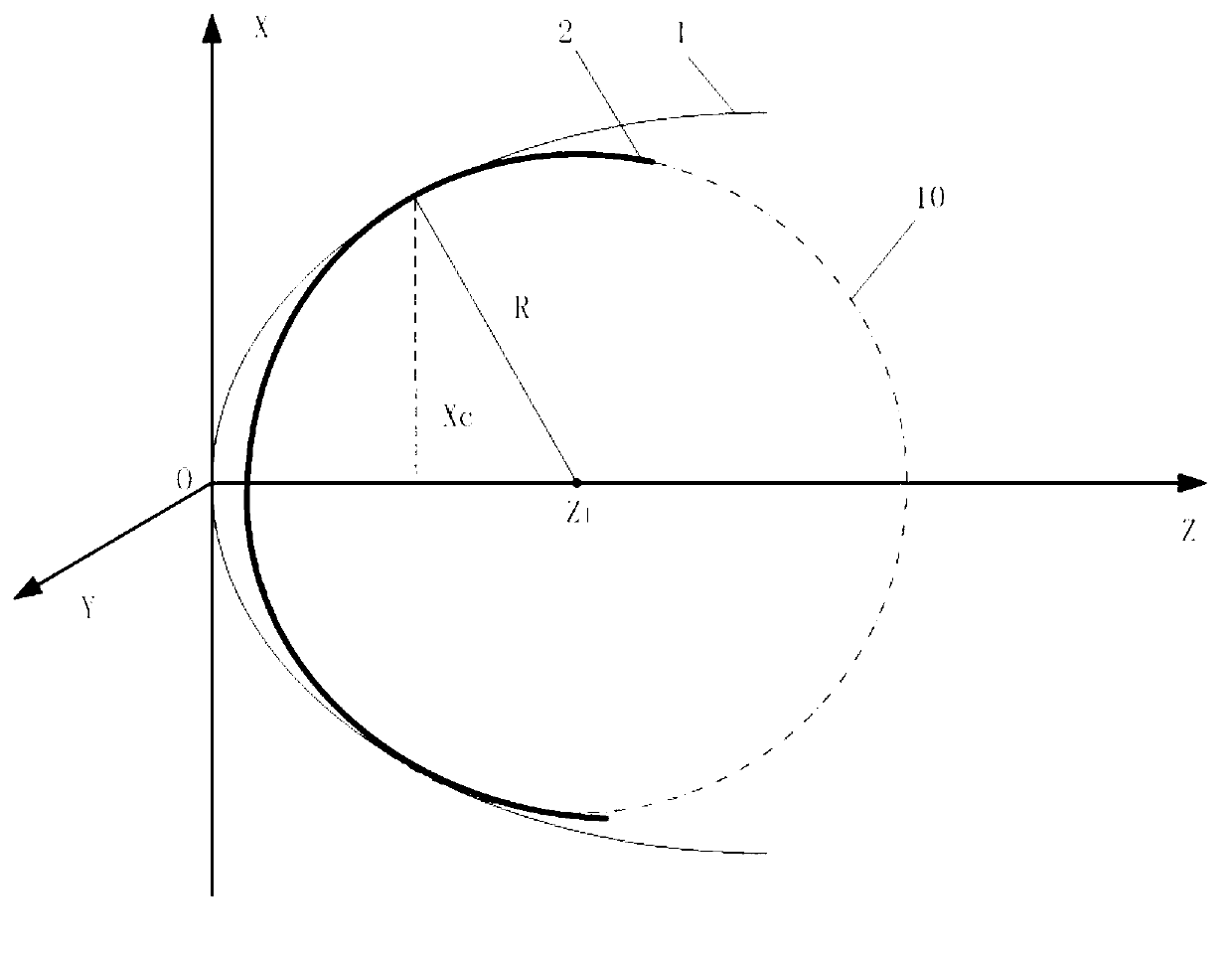

[0031] Such as figure 1 As shown, the device of a full-aperture optical aspheric surface error direct detection system of the present invention includes an interferometer 3, a standard spherical transmission lens 4, a one-dimensional electronically controlled translation stage 5, a five-dimensional precision electronically controlled platform 6, and a computer system 7 composition. The standard spherical transmission lens 4 is fixed in front of the interferometer 3, and the optical axes of the two are on the same straight line; the measured optical aspheric surface 1 is fixed on the five-dimensional precision electronic control platform 6, and the five-dimensional precision electronic control platform is adjusted by the computer system 7. The control platform 6 makes the optical axes of the measured optical aspheric surface 1, the standard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com