Method for making tissue chip based on one-step molding

A tissue chip and manufacturing method technology, applied in the field of tissue chips, can solve the problems of burr in each hole, difficult to precisely control the drilling depth, difficult to take out the core column, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the examples.

[0017] 1. Prepare the mold frame and embedding frame for making tissue chips:

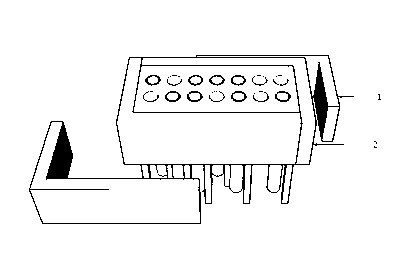

[0018] Such as figure 1 Shown is a schematic diagram of the tissue chip casting mold frame, which is composed of a chip array orifice plate and an embedding tube. There are supports around the mold frame, and the height of the position is controlled by nuts. The embedding frame of the tissue chip is composed of two vertically bent copper strips, with a length of 70mm, a width of 40mm, and a height of 20mm, which can be freely separated and assembled into rectangles with different internal diameters.

[0019] 2. Tissue sampling:

[0020] According to the tissue to be prepared, find out and mark the target tissue area. According to the size of the target area, select a flat knife with an appropriate width, and cut vertically downward along the marked line to obtain a tissue block with the same diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com