Automatic cutter for optical fibers

A technology of cutting knife and automatic cutting knife, which is applied to the coupling of optical waveguides and other directions, can solve the problems of manual push knife force, different speed, difficult to guarantee fiber cutting quality, and complicated operation of fiber cutter, so as to improve the optical fiber. Cut quality, compact structure, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

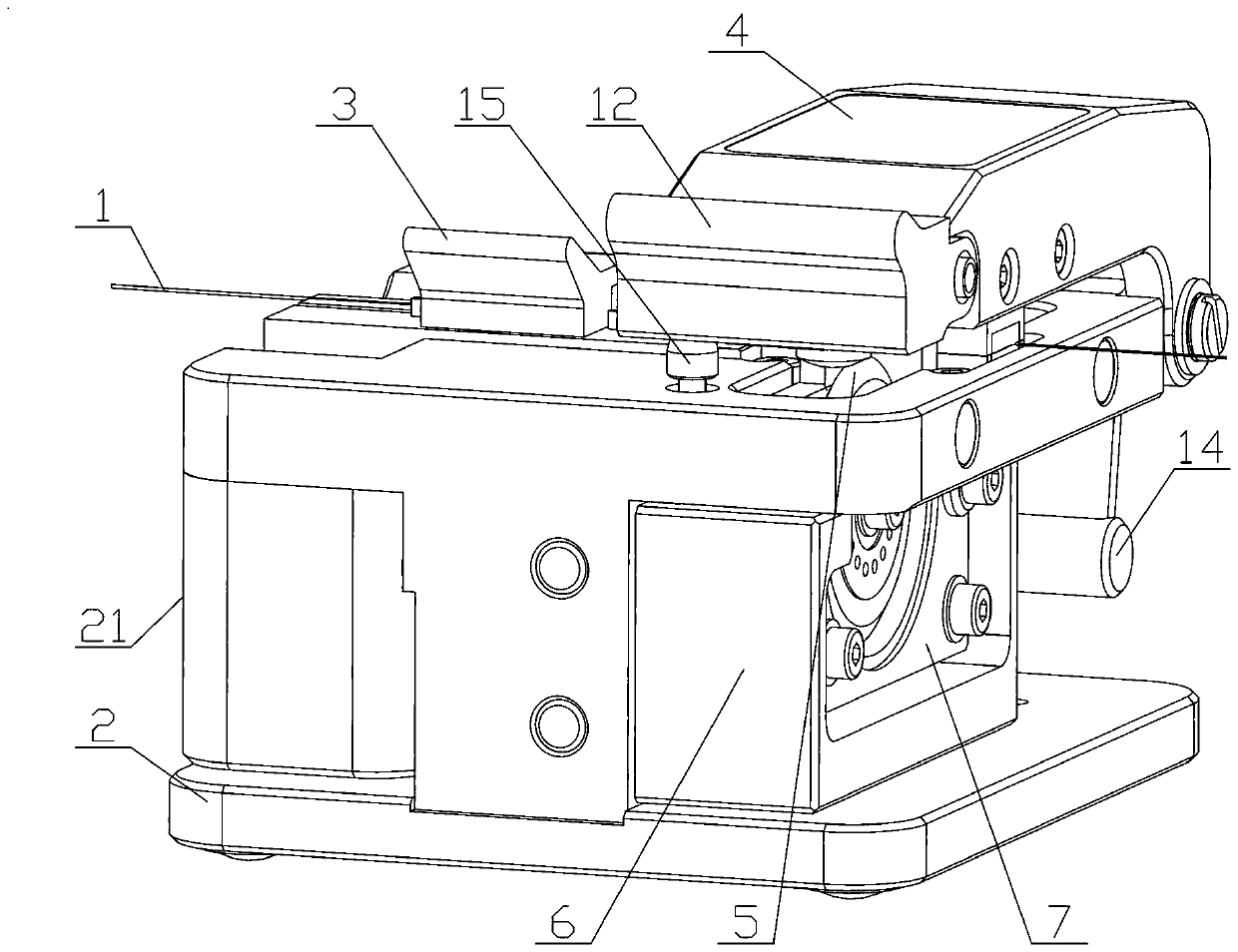

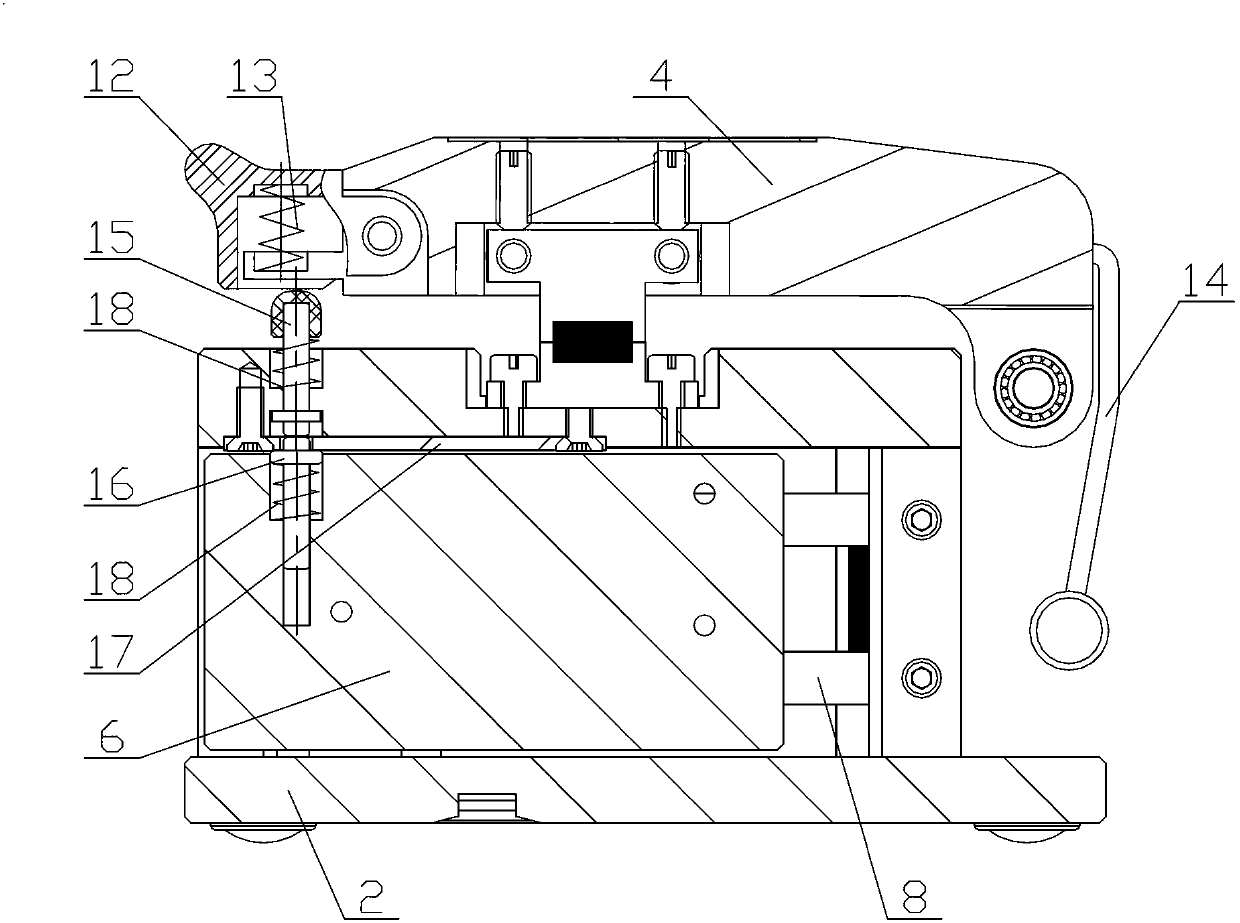

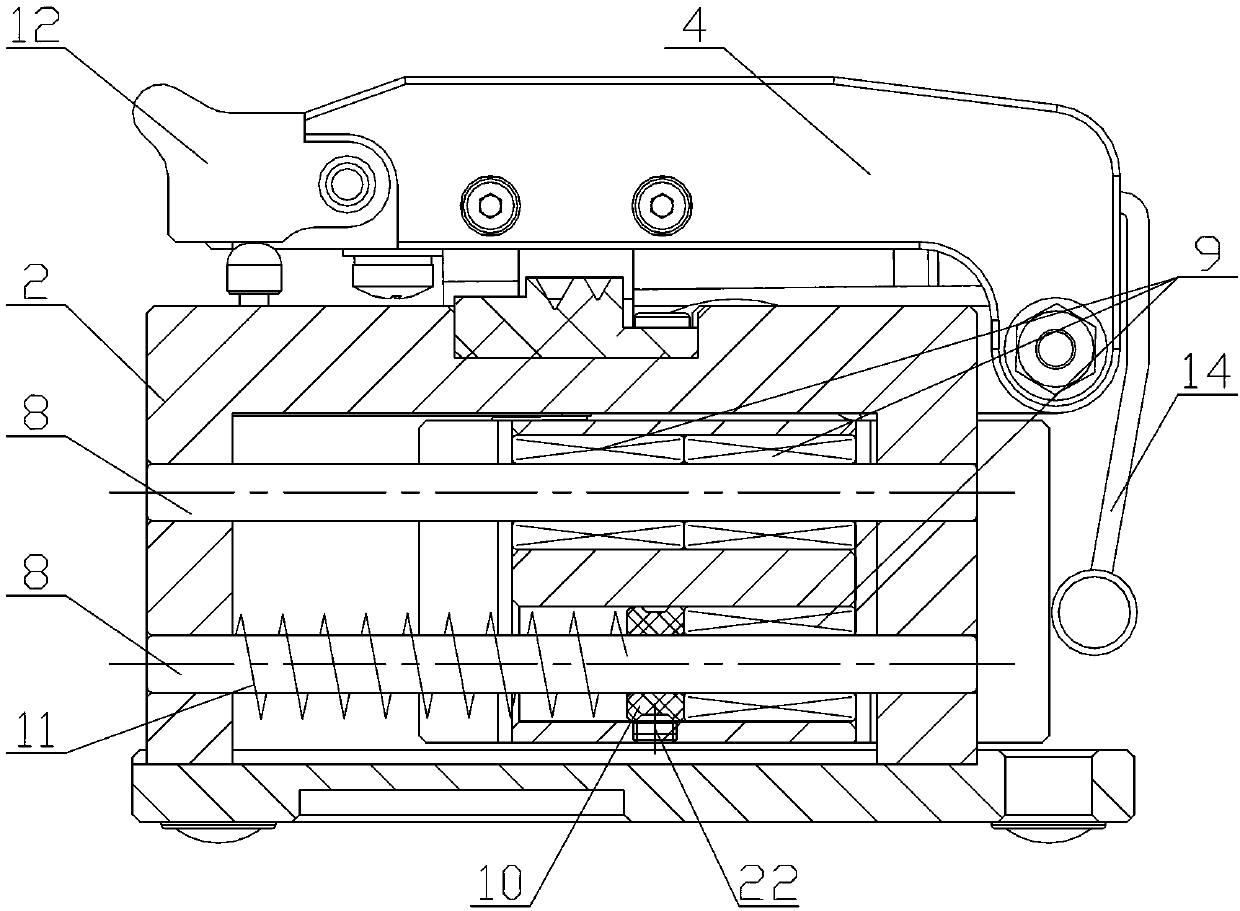

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] Such as Figure 1-7 As shown, in this embodiment, an automatic optical fiber cutter according to the present invention includes a base 2 for installing an optical fiber 1, the base 2 is provided with a guide groove for the optical fiber 1, and the guide groove for the optical fiber 1 passes through The compression screw is installed on the base 2, and the base 2 on the side of the guide groove of the optical fiber 1 is respectively hinged with a large pressure plate 4 and a small pressure plate 3, and the large pressure plate 4 is provided with two upper rubber presser feet, and the two A fiberizer is arranged between the rubber presser feet, a cutting groove is arranged on the base 2 below the large presser plate 4, and a lower rubber presser foot is arranged on both sides of the cutting gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com