TM dielectric resonator, realizing method thereof and TM dielectric filter

A dielectric resonator and dielectric resonance technology, applied in the field of communication, can solve the problems of high structural design requirements, unfavorable mass production, complex assembly process, etc., and achieve the effect of improving performance and working reliability, facilitating mass production, and simple welding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

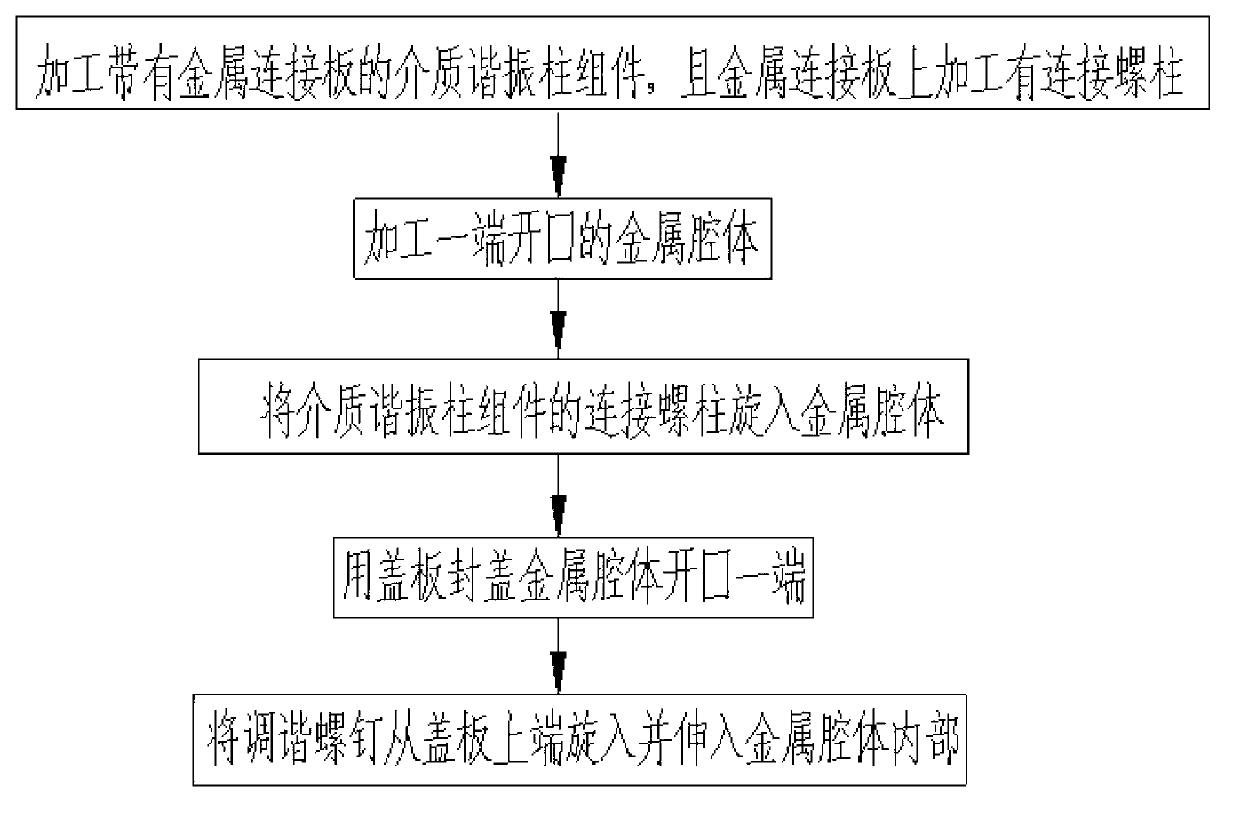

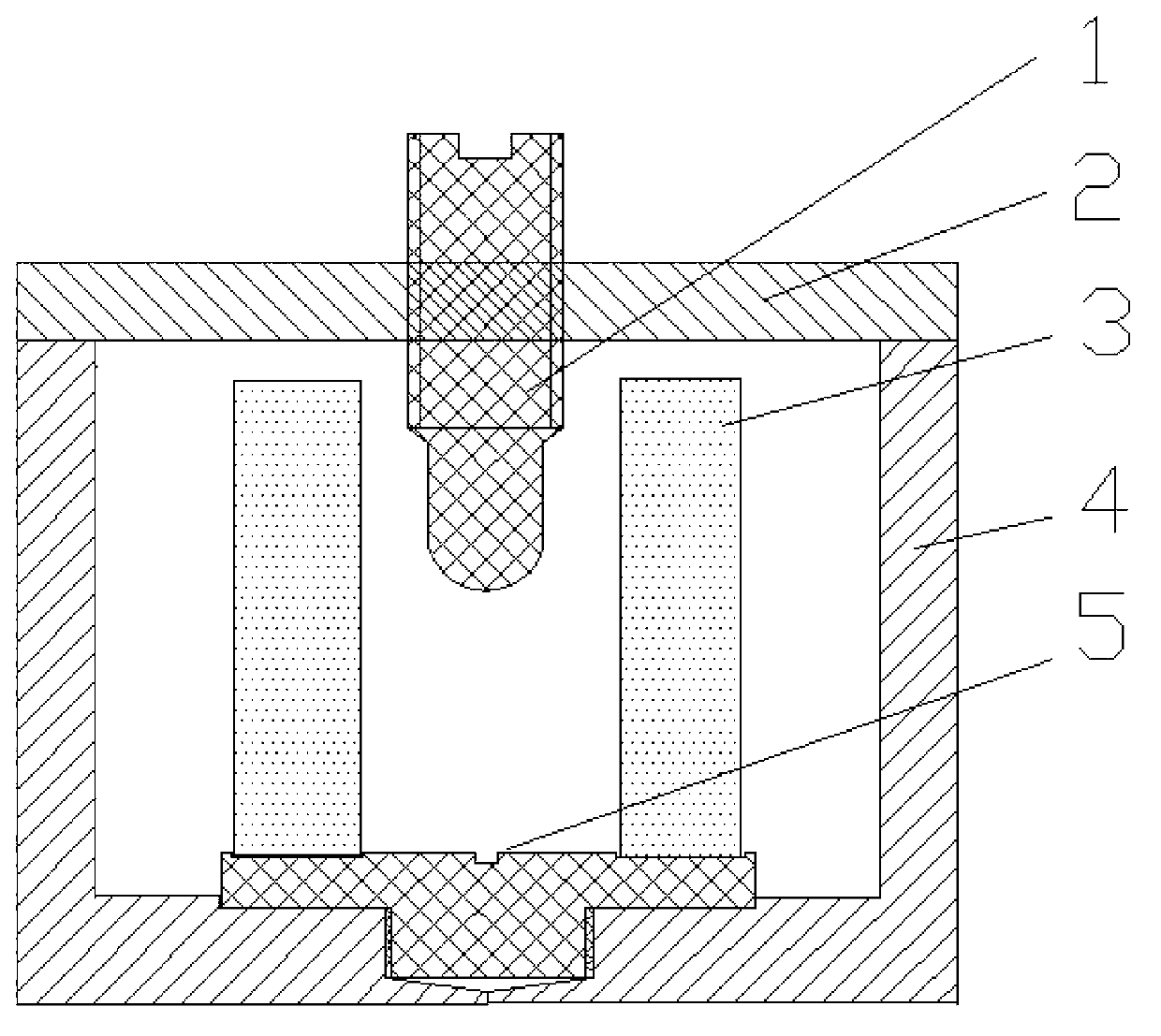

[0035] Such as figure 2 As shown, the TM dielectric resonator implementation method of the present invention comprises the following steps:

[0036] Process dielectric resonance column components with metal connecting plates, and connecting studs are processed on the metal connecting plates;

[0037] Process the metal cavity 4 with one end open;

[0038] Screw the dielectric resonant column assembly with the metal connecting plate into the inner wall of the metal cavity 4 by using the connecting stud;

[0039] Cover the opening of the metal cavity 4 with a prefabricated cover plate 2;

[0040] Screw the prefabricated tuning screw 1 from the cover plate 2 into the metal cavity 4 .

[0041] Specifically, the present invention firstly processes a dielectric resonant column assembly with a metal connecting plate, and the metal connecting plate is processed with a connecting stud, and secondly processes a metal cavity with an opening at one end, and then uses the connecting stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com