Method for mounting anti-waving spacers on 66-kilovolt power transmission hot-line

A technology of transmission lines and spacer bars, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to install equipotential spacer bars, unsatisfactory distances, and incomplete applicability, so as to reduce power outage installation time, reduce danger, Realize the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

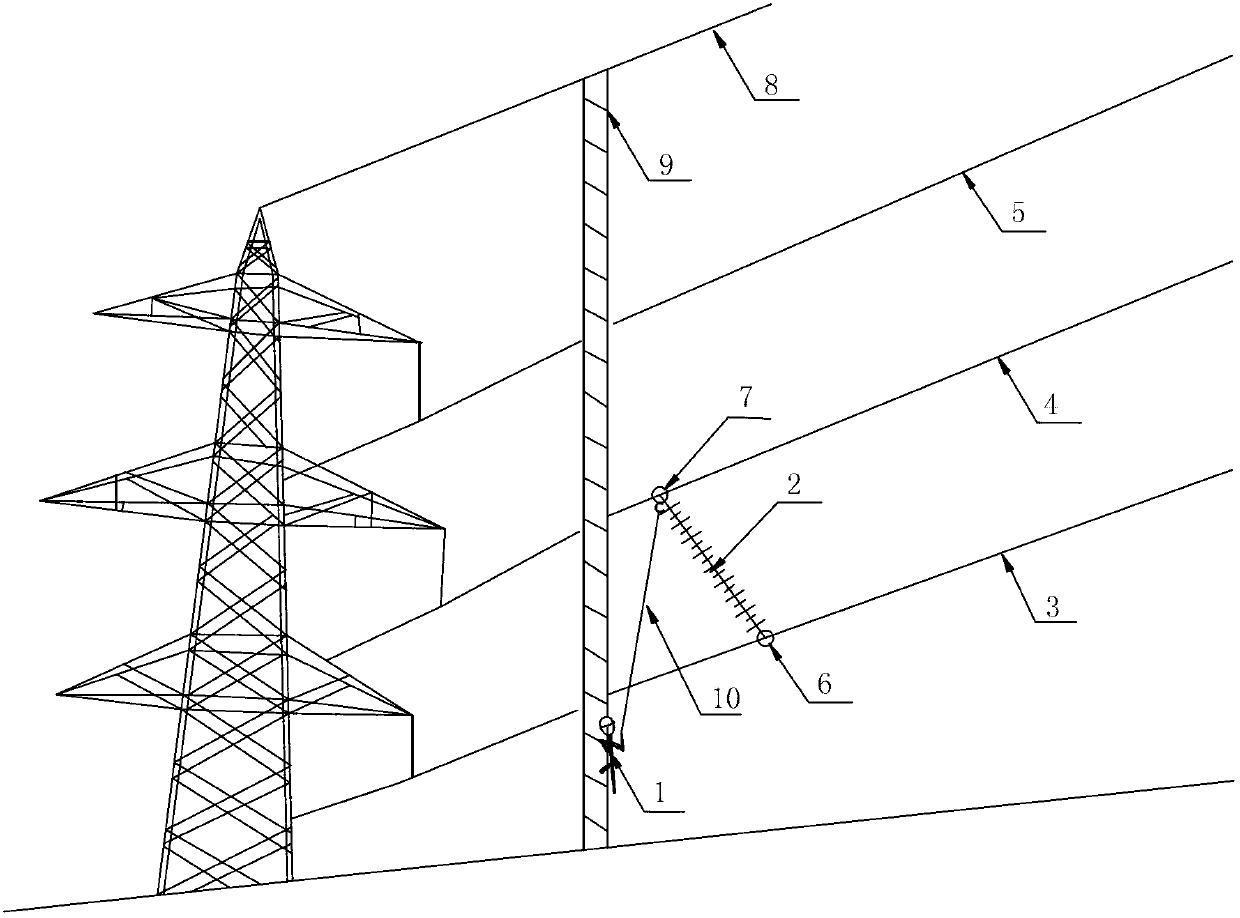

[0017] See figure 1 , is a schematic diagram of an embodiment of the live installation method of the anti-galling spacer bar on the 66 kV transmission line of the present invention. The live operator 1 first adopts the equipotential operation method to fix one end of the anti-galling spacer bar 2 on the lower conductor 3 of the transmission line, and then Then use the intermediate potential operation method to connect and fix the other end of the anti-galling spacer 2 with the middle conductor 4, so as to avoid the risk of a second equipotential operation by live workers and realize live installation. The specific operation steps are as follows:

[0018] 1) At the beginning of the operation, the ground operators carefully check the insulating rope to confirm that there is no damage or deformation; the ground operators use a 2500kV and above insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com