Constant-current drive circuit used for LED (Light Emitting Diode) lamp

A LED lamp, constant current drive technology, applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problems of complex structure and high cost of LED lamp drive circuit, achieve good application prospects, low production cost, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

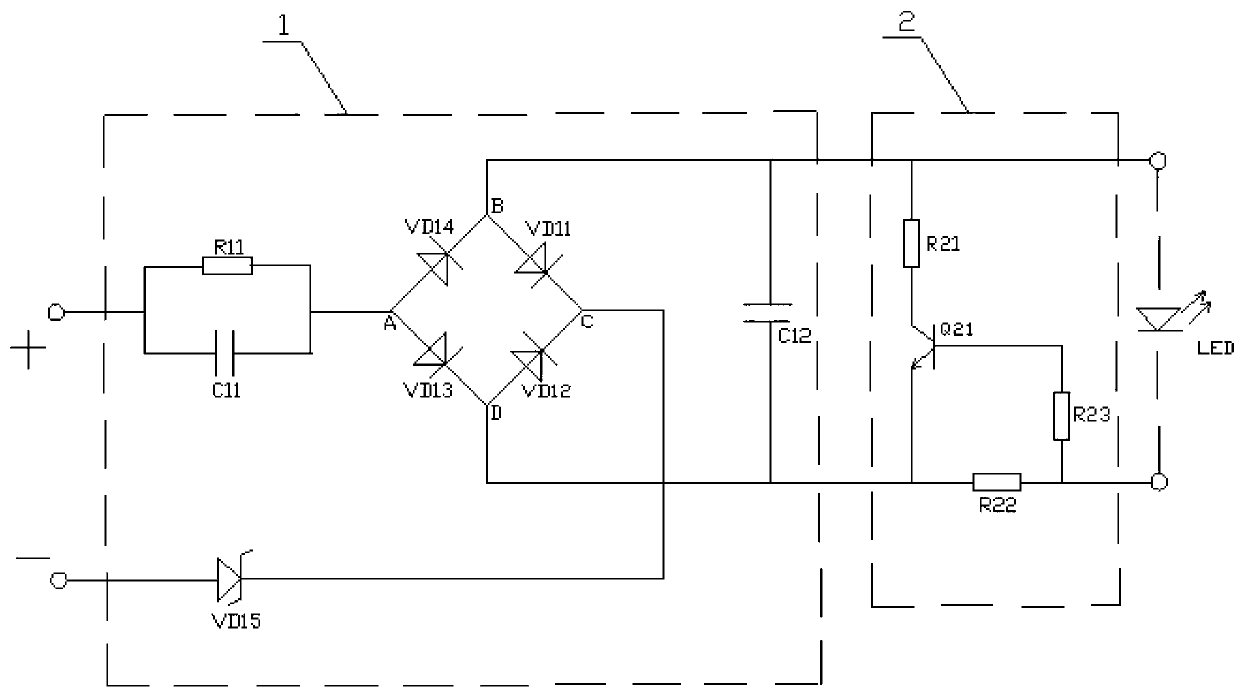

[0012] A constant current drive circuit for LED lights, such as figure 1 Shown: It includes the resistance-capacitance step-down circuit 1, which uses the capacitive reactance generated by the capacitor at the frequency of the AC signal to limit the maximum operating current of the LED lamp of the load, so as to ensure that the LED lamp will not burn out, and also includes the constant current circuit 2, which is connected to the Between the resistance-capacitance step-down circuit 1 and the LED lamp of the load, the current of the LED lamp can be kept constant, so as to prevent the LED lamp from burning out due to unstable external voltage.

[0013] Among them, the constant current circuit 2 is composed of a triode Q21 and three resistors R21, R22, and R23. One end of the resistor R21 and the current sampling resistor R22 are respectively connected to the anode and cathode of the output end of the RC step-down circuit 1, and the other end of the resistor R21 It is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com