Production process of collagen yoghourt

A collagen yogurt and production process technology, applied in the field of collagen yogurt production technology, can solve the problems of unguaranteed quality and safety, great influence of growth environment pollution, and failure to meet safety performance, etc., to achieve enhanced beauty and health care effects , strong nutritional complementarity and functional coordination, and the effect of high beauty and health care value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

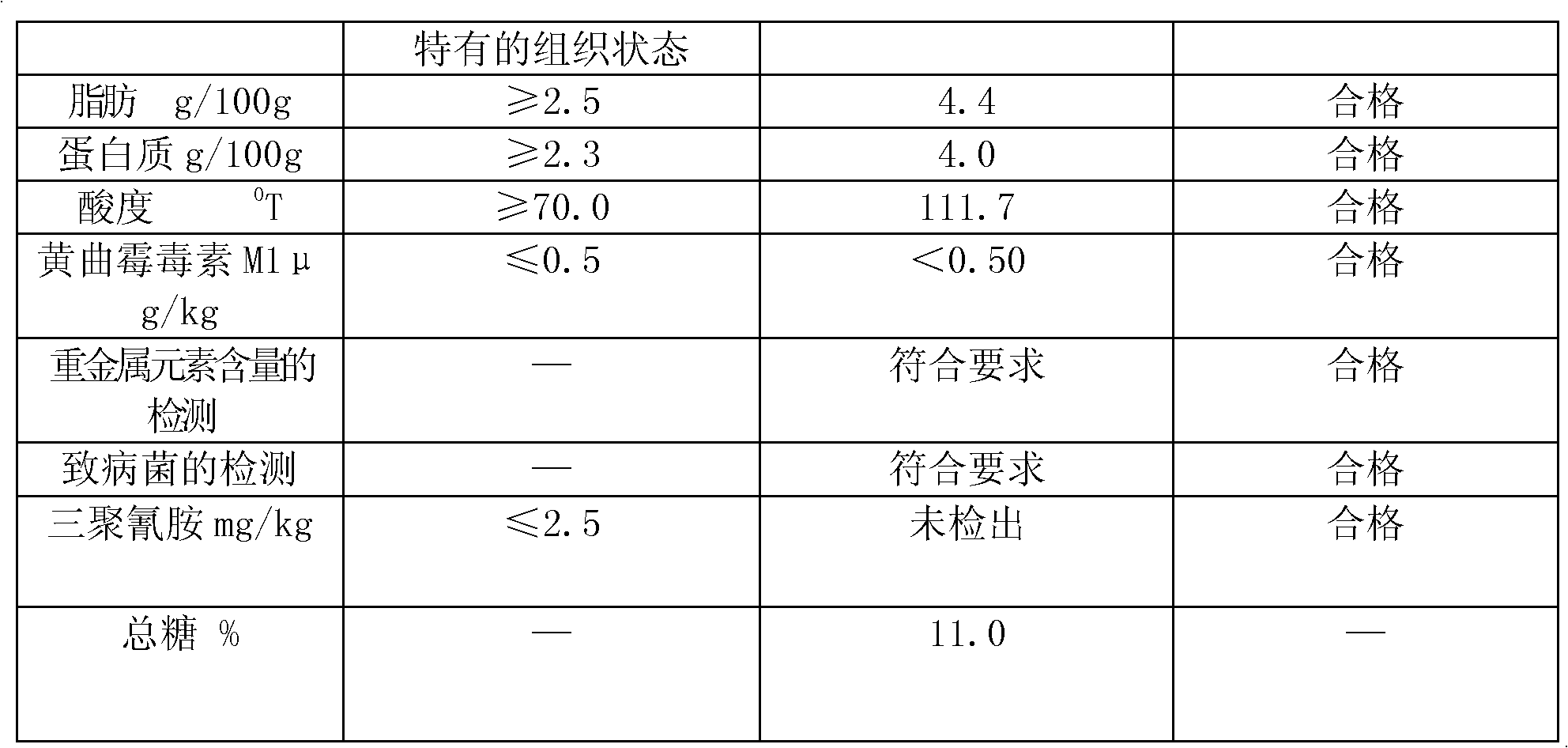

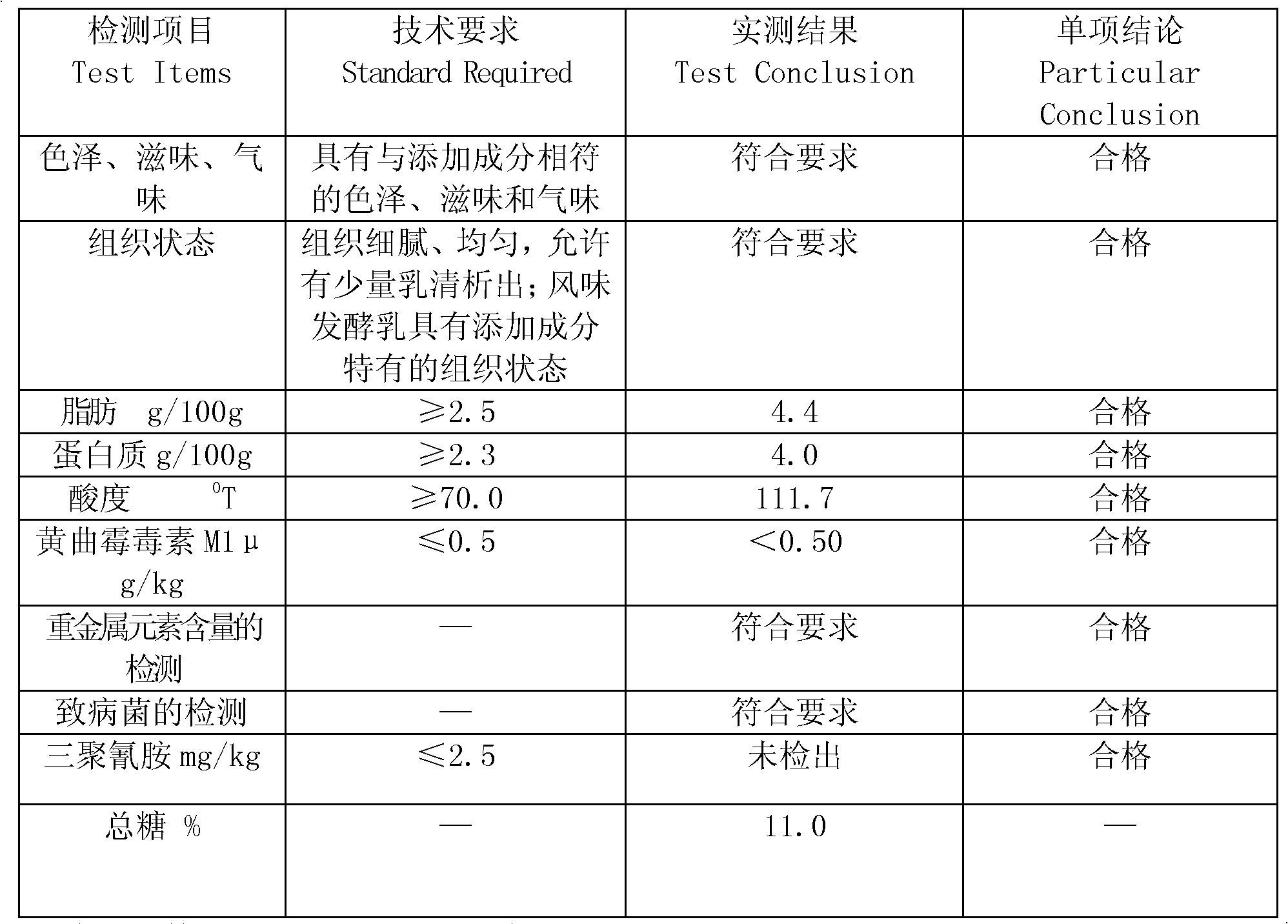

Embodiment 1

[0041] Check and accept the raw milk (i.e. carry out alcohol test, acidity test, specific gravity test, fat content test, and melamine test on the milk) to meet the corresponding standards, and filter, purify, cool and store the qualified raw milk. The raw milk is preheated by a heat exchanger, poured into a mixing tank, adding collagen accounting for 1% of milk weight and 6.5% white sugar accounting for milk weight, stirring and mixing evenly. The mixture of collagen and white sugar is pumped into the plate heat exchanger to preheat to 70°C, and homogenized by a high-pressure homogenizer. The first stage of homogenization pressure is 18MPa, and the second stage is 5MPa. After homogenization Put the material into the sterilizer for sterilization. The sterilization condition is controlled at 95°C for 5 minutes. The sterilized material is pumped into the vacuum concentration tank, concentrated to a solid content of 22%, and the concentrated milk is pumped into the yogurt fermenta...

Embodiment 2

[0047] Check and accept the raw milk (i.e. carry out alcohol test, acidity test, specific gravity test, fat content test, and melamine test on the milk) to meet the corresponding standards, and filter, purify, cool and store the qualified raw milk. The raw milk is preheated by a heat exchanger, poured into a mixing tank, adding collagen accounting for 1% of the milk weight and white sugar accounting for 7% of the milk weight, stirring and mixing evenly. The mixture of collagen and white sugar is pumped into the plate heat exchanger to preheat to 70°C, and homogenized by a high-pressure homogenizer. The first stage of homogenization pressure is 18MPa, and the second stage is 5MPa. After homogenization Put the material into the sterilization tank for sterilization. The sterilization condition is controlled at 90°C for 5 minutes. The sterilized material is pumped into the vacuum concentration tank, concentrated to a solid content of 20%, and the concentrated milk is pumped into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com