Lactobacillus-fermented and zinc gluconate-strengthened lactobacillus beverage and production process thereof

A zinc gluconate, lactic acid bacteria beverage technology, applied in dairy products, applications, milk preparations and other directions, can solve the problems of large investment in production equipment, no lactic acid bacteria beverages, and limited product marketing, etc., to achieve technical convenience, regulate intestinal bacteria. group effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further illustrate the lactic acid bacteria fermented and fortified zinc gluconate lactic acid bacteria beverage and the production process of the present invention, the test data are now given.

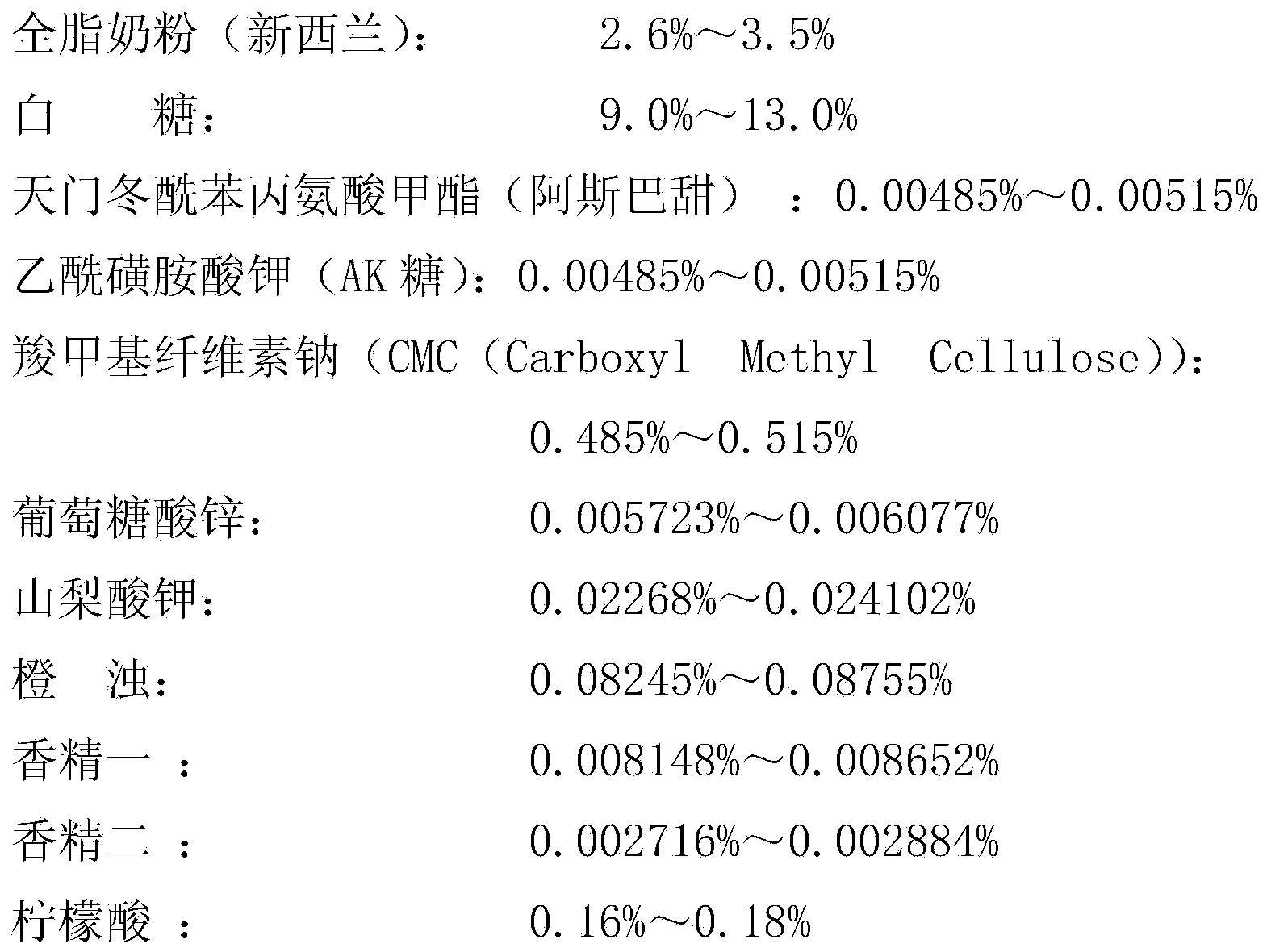

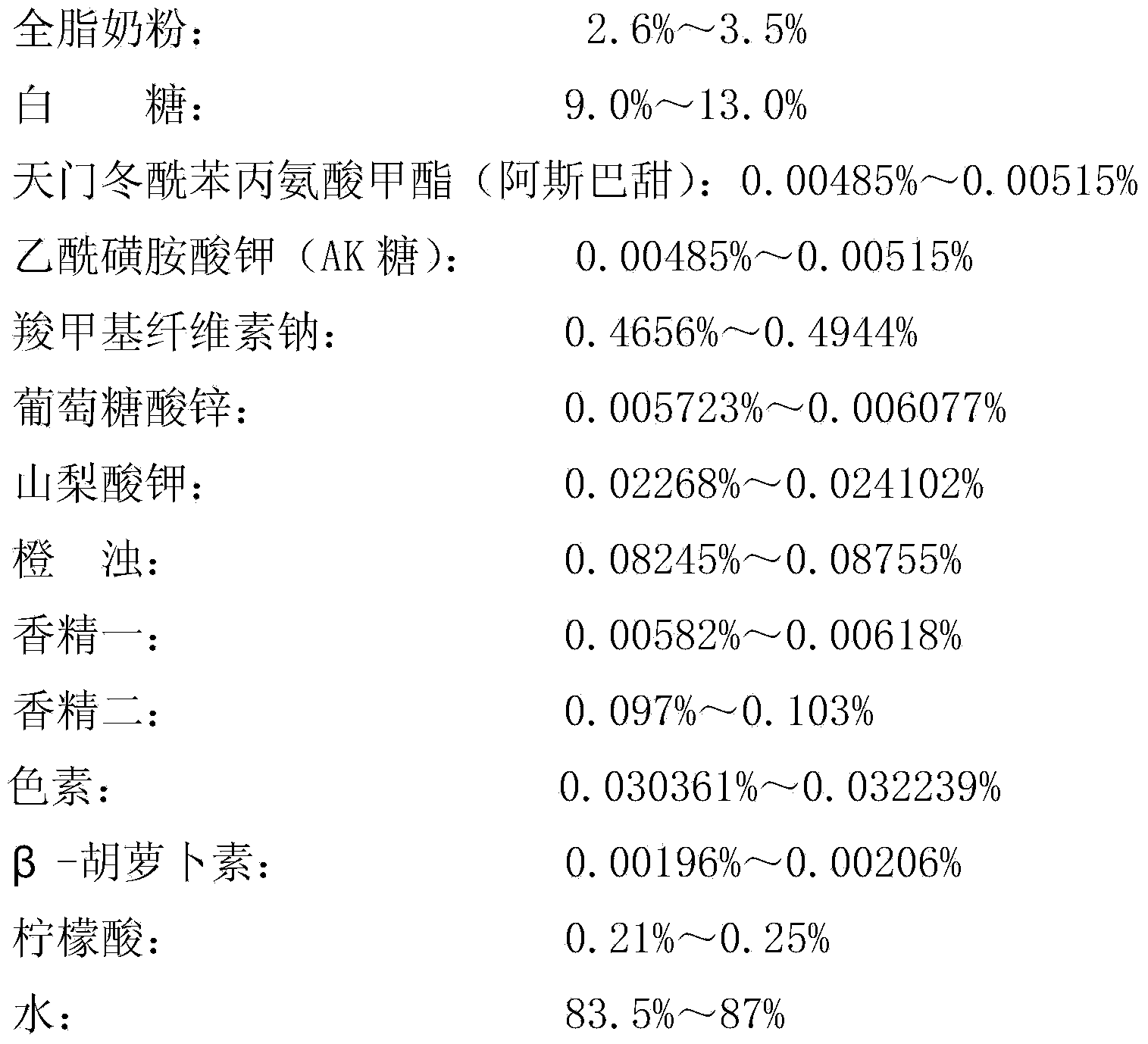

[0066] A kind of lactic acid bacteria fermented and strengthened zinc gluconate lactic acid bacteria beverage is manufactured, and the original taste type strengthened zinc gluconate lactic acid bacteria beverage comprises by weight:

[0067]

[0068] The amount of citric acid added is calculated according to the following formula:

[0069] W=(W 1 ×A 1 %-W 2 ×A 2 %)×0.78

[0070] W: weight of citric acid added (㎏)

[0071] W 1 : The total weight of the designed and produced finished product (㎏)

[0072] A 1 : The acidity of the designed and produced finished product is 0.43% to 0.45% in terms of lactic acid

[0073] A 2 : Ripe fermented milk acidity (as lactic acid %)

[0074] W 2 : The total weight of fermented milk (㎏), which is W 1 ×22.1%

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com