A kind of heat-processed white mushroom color-protecting agent and its application

A white mushroom and thermal processing technology, applied in the fields of application, food ingredient function, food science, etc., can solve problems such as residue, tank wall corrosion, and unfavorable human health, and achieve scientific formula, low browning degree, and color protection effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

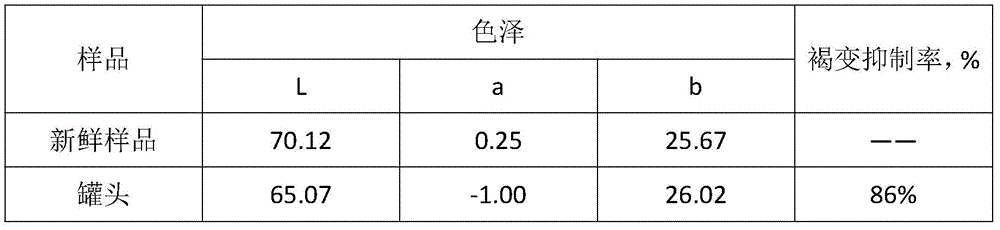

[0023] Embodiment 1 Application of color-protecting agent of the present invention in canned white mushroom

[0024] After the fresh white mushrooms are harvested, cut off the muddy root stalks, wash and slice them, and immediately immerse them in the color-protecting solution for color-protecting treatment. The formula of the color-protecting solution is 3% calcium ascorbate, 0.5% calcium propionate, and 0.8% sodium chloride , 0.1% L-cysteine, 0.02% disodium ethylenediaminetetraacetate, color protection conditions: soaking treatment at 20°C for 15min, solid-liquid ratio 1:8, then blanching at 100°C for 1 minute, cooling and draining Dry, weigh, add soup to cans, sterilize and cool (10′-30′-10′ / 121°C, that is, raise the temperature to 121°C in 10 minutes, keep warm for 30 minutes, cool down in 10 minutes), and put it in a 37°C incubator In 3 days, measure the sample browning inhibition rate (R) and color and luster (L, a and b value), the result is as shown in table 1 (fresh s...

Embodiment 2

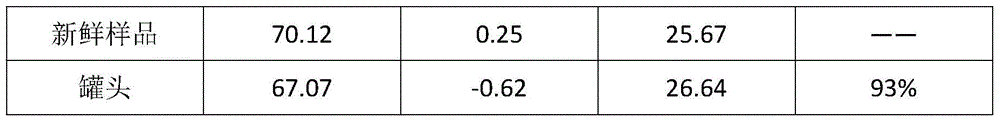

[0027] Embodiment 2 Application of color-protecting agent of the present invention in canned white mushroom

[0028] After the fresh white mushrooms are harvested, cut off the muddy root stalks, wash and slice them, and immediately immerse them in the color-protecting solution for color-protecting treatment. The formula of the color-protecting solution is 4% calcium ascorbate, 1.5% calcium propionate, and 1.2% sodium chloride , 0.2% L-cysteine, 0.02% disodium ethylenediaminetetraacetate, color protection conditions: soaking at 25°C for 25min, solid-liquid ratio 1:12, then blanching at 100°C for 1 minute, cooling and draining, Weighing, canning and adding soup, sterilizing and cooling (10′-30′-10′ / 121°C), placed in a 37°C incubator for 3 days, and measuring the browning inhibition rate (R) and color (L, a and b value), the results are shown in Table 2.

[0029] Table 2 Color and browning degree of canned white mushrooms

[0030]

[0031]

Embodiment 3

[0032] Embodiment 3 Application of color-protecting agent of the present invention in white mushroom drying

[0033] After the fresh white mushrooms are harvested, cut off the stalks with mud, wash and slice them, and immediately immerse them in the color-protecting solution for color-protecting treatment. The formula of the color-protecting solution is 5% calcium ascorbate, 2% calcium propionate, and 1.5% sodium chloride , 0.3% L-cysteine, 0.03% disodium ethylenediaminetetraacetate, color protection conditions: soaking treatment at room temperature for 30 minutes, solid-to-liquid ratio 1:15, then blanch at 100°C for 1 minute, cool and drain , dried with hot air at 50°C for 10 hours, cooled and packaged, and placed in a 37°C incubator for 3 days to measure the browning inhibition rate (R) and color (L, a and b values) of the sample. The results are shown in Table 3.

[0034] Table 3 Color and browning degree of dried white mushroom

[0035]

[0036] The canned white mushro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com