Device and method for determining breathing heat of livestock open type mask

An open-circuit, livestock technology, applied in diagnostic recording/measurement, medical science, sensors, etc., can solve problems such as difficult to imitate natural air pressure, difficult to ensure normal natural breathing of livestock, etc., to achieve the effect of small disturbance of livestock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

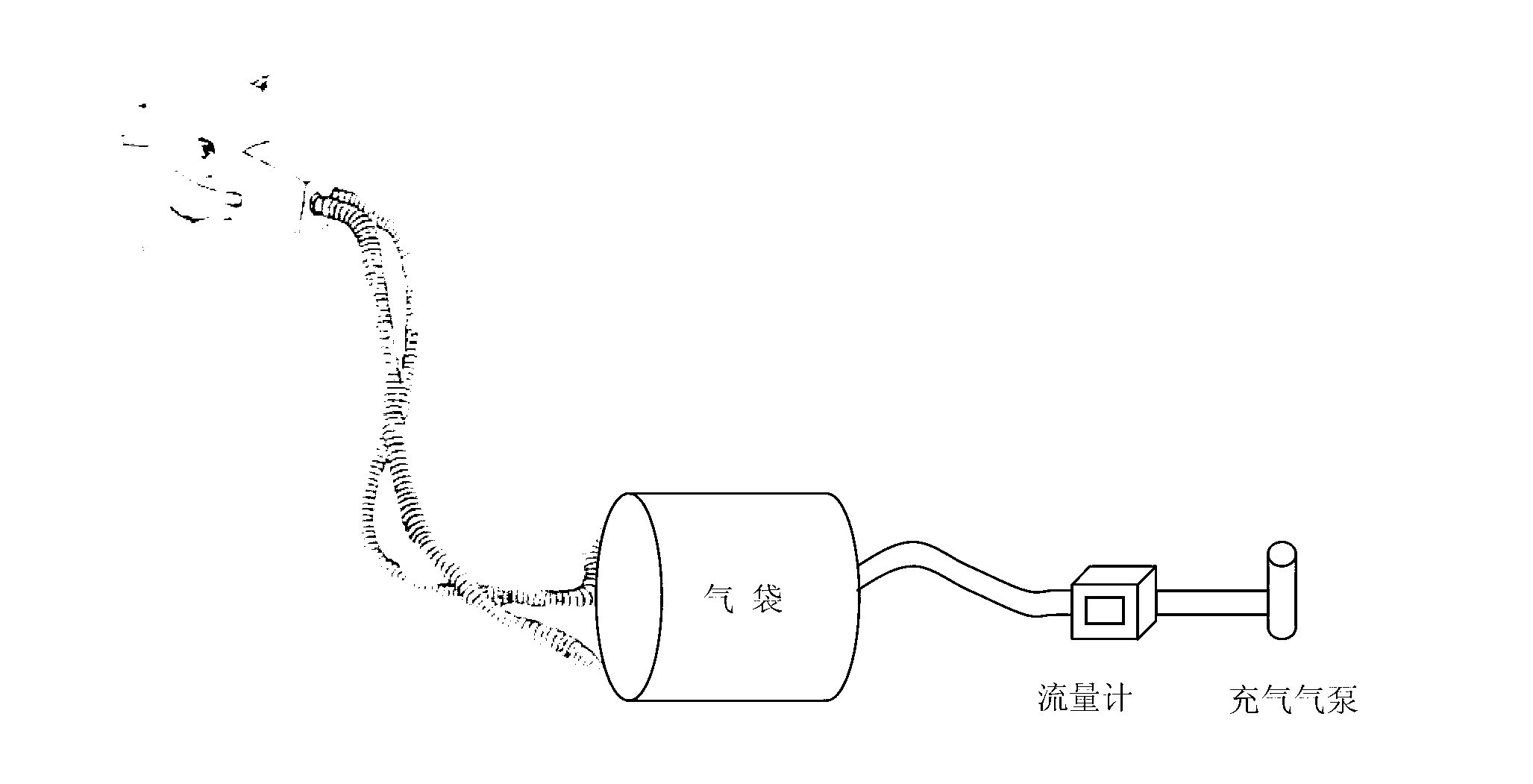

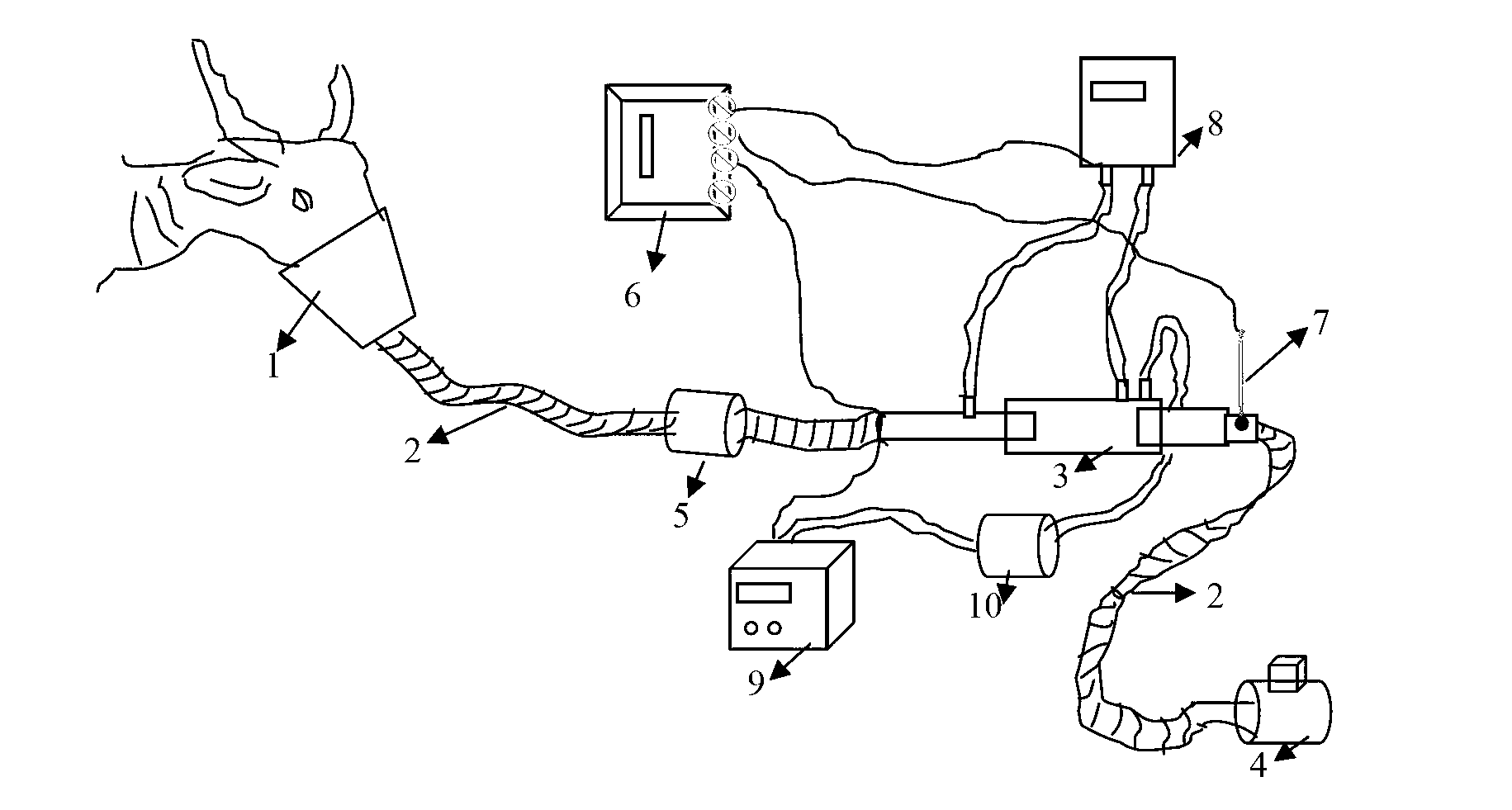

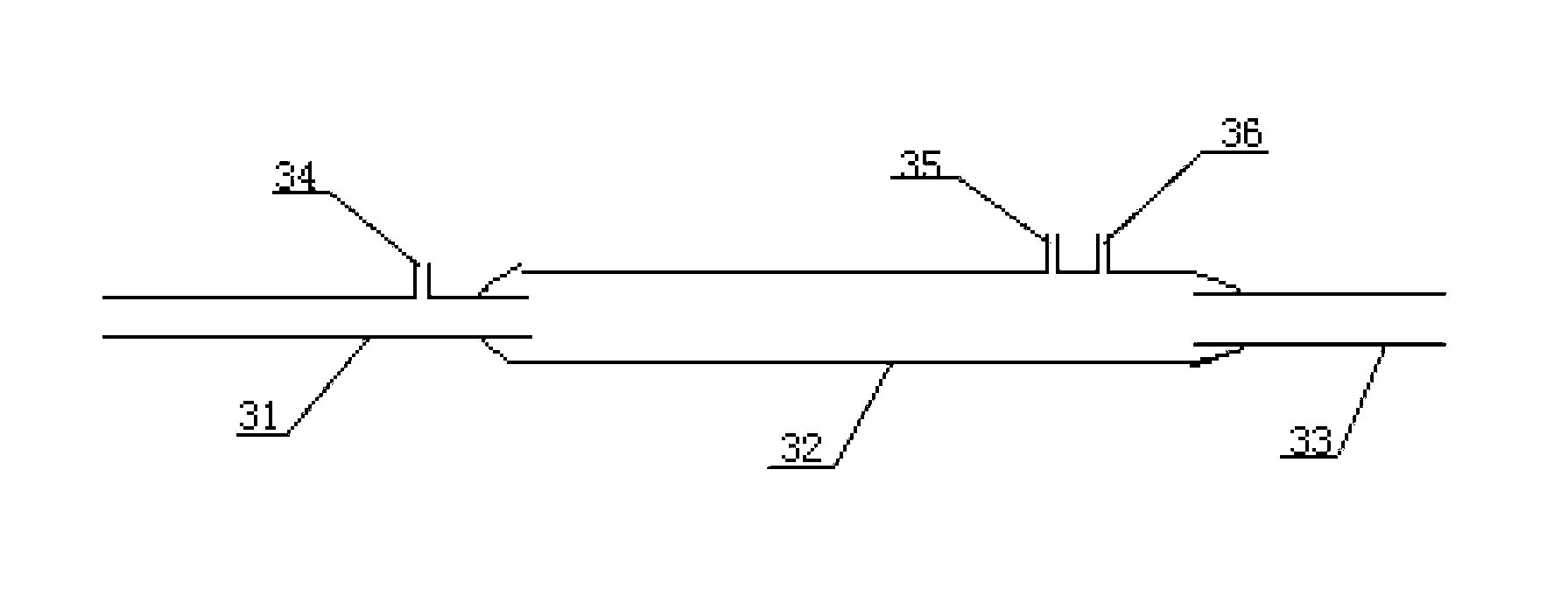

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a livestock open-circuit mask respiratory calorimetry device includes a breathing mask 1, and the breathing mask 1 is provided with inhalation and exhalation pipelines, and the inhalation and exhalation pipelines are one The pipeline also includes an exchanger 3, and the exchanger 3 includes a high-pressure diameter pipe 31 and a low-pressure diameter pipe 32. The high-pressure diameter pipe 31 is arranged on one end of the low-pressure diameter pipe 32 and communicates with the low-pressure diameter pipe 32; The diameter pipe 31 is provided with the inlet connection end 34 of the pressure difference measuring instrument, and the low pressure diameter pipe 32 is provided with the air outlet connection end 35 of the pressure difference measuring instrument; The air pump 4 is connected; the breathing mask 1 is connected with the high-pressure diameter pipe 31 of the exchanger 3 through the flexible ...

Embodiment 2

[0028] Embodiment 2: Same as Embodiment 1, the pipe diameter of the low-pressure diameter pipe of the described exchanger is 42 mm, and the pipe diameter of the high-pressure diameter pipe of the described exchanger is 18 mm. The distance between the gas input pipe of the differential pressure measuring instrument and the gas output pipe of the differential pressure measuring instrument is 25 cm. The flow rate of the sealed pump is 1mL / min, and the power is 50HZ.

Embodiment 3

[0029] Embodiment 3: Same as Embodiment 1, except that the diameter of the low-pressure diameter pipe of the described exchanger is 46 mm, and the pipe diameter of the high-pressure diameter pipe of the described exchanger is 25 mm. The distance between the gas input pipe of the differential pressure measuring instrument and the gas output pipe of the differential pressure measuring instrument is 40 cm. The flow rate of the sealed pump is 4mL / min, and the power is 60HZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com