CO2 absorbent and preparation method thereof

An absorbent and a certain amount of technology, applied in the field of CO2 absorbent and its preparation, can solve the problem of low metal oxide capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

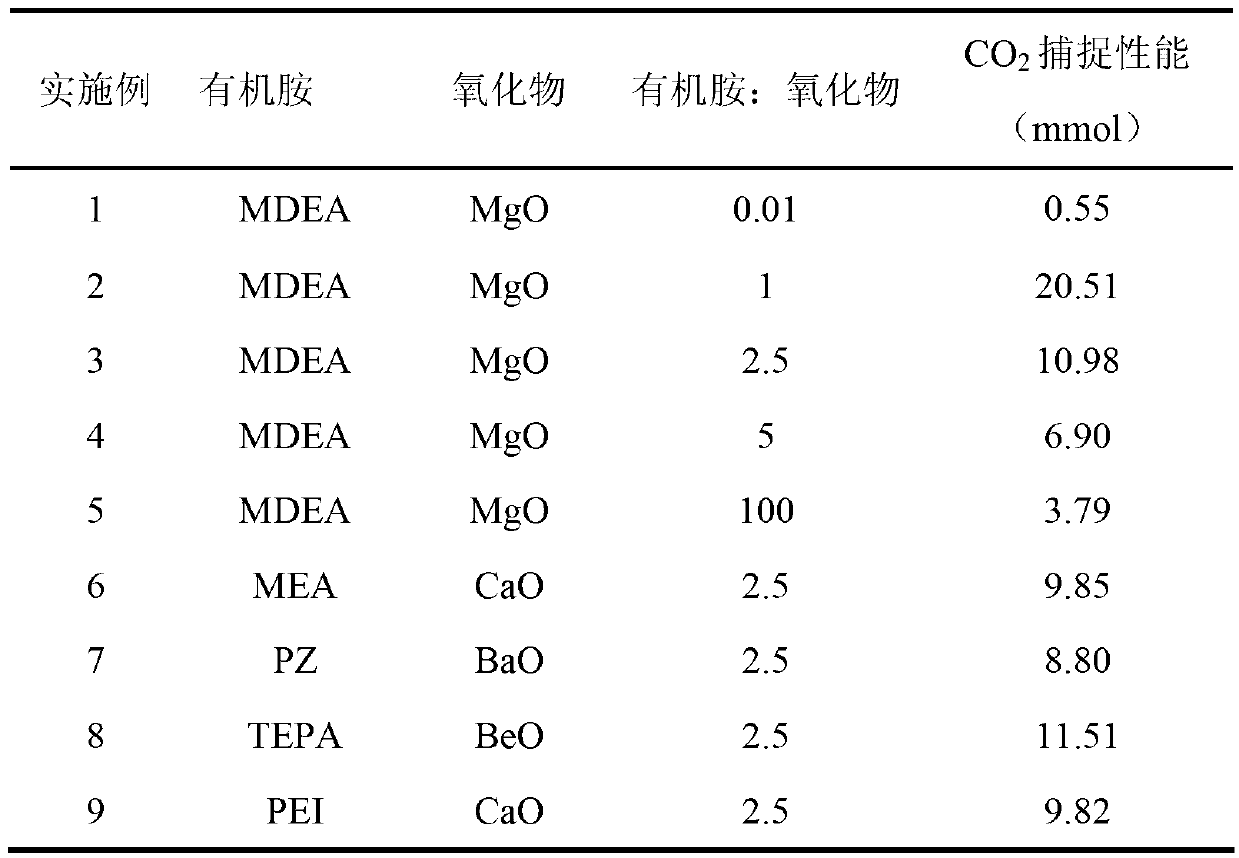

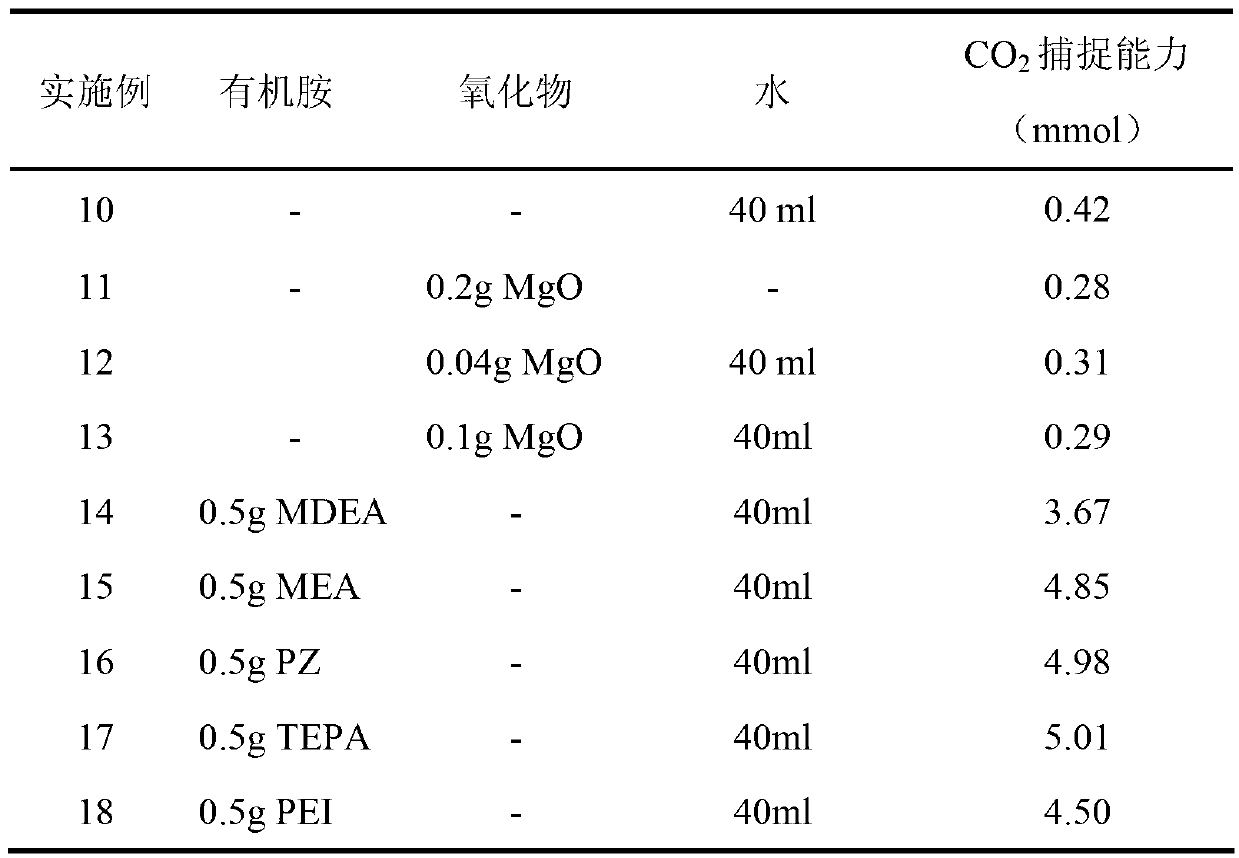

[0015] Preparation of organic amine-metal oxide composite absorbent: Dissolve 0.05 g of organic amine N-methyldiethanolamine (MDEA) in 400 ml of water, then add 5 g of basic metal oxide magnesium oxide, ultrasonicate for 10 minutes, and evenly dissolve magnesium oxide Suspended and dispersed in MDEA aqueous solution to prepare MDEA-MgO composite absorbent.

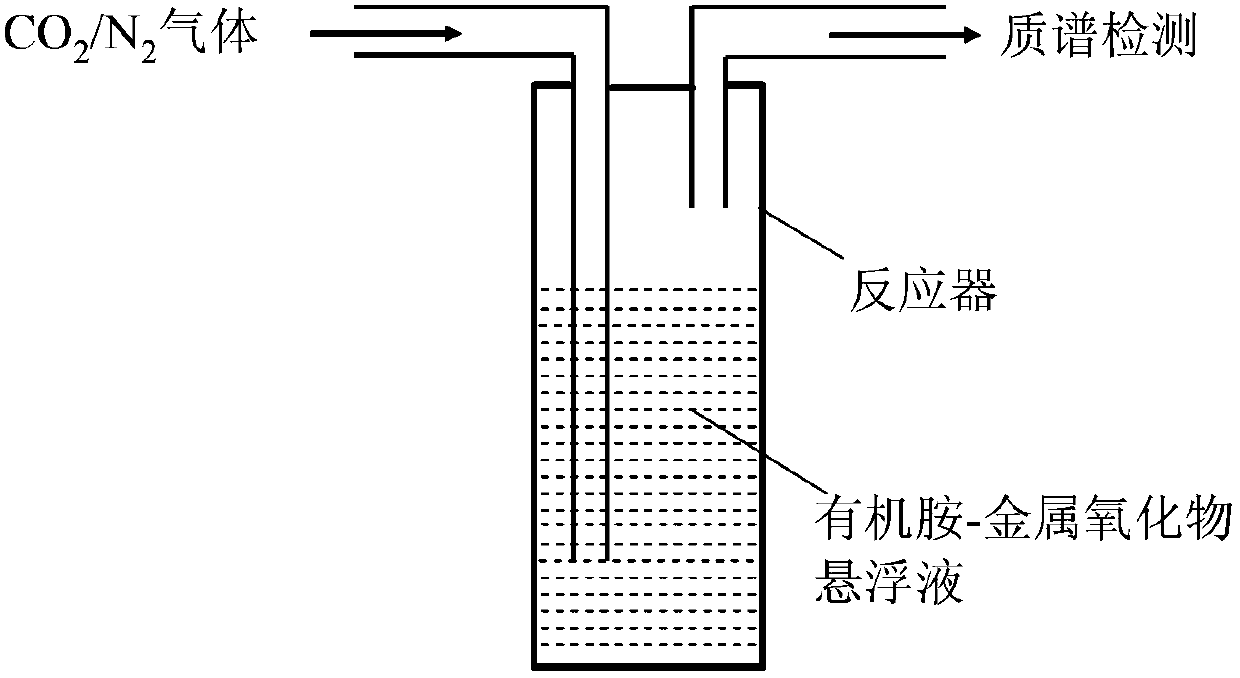

[0016] In a 50ml glass reactor, the CO 2 For the capture capacity test, 40.5ml of the above-mentioned composite absorbent is loaded into a glass reactor, and the absorption temperature is controlled at 25°C. CO was introduced into the reactor 2 and N 2 , CO 2 The flow rate is 5ml / min, N 2 The flow rate is 45ml / min. CO 2 and N 2 After mixing, it enters the reactor, and the gas reaction product is analyzed by mass spectrometry after being absorbed by the absorbent. Absorbent captures CO 2 The capabilities can be seen in Table 1. The flow chart of the reaction device is attached figure 1 .

Embodiment 2

[0018] Preparation of organic amine-metal oxide composite absorbent: Dissolve 5 g of organic amine N-methyldiethanolamine (MDEA) in 400 ml of water, then add 5 g of basic metal oxide magnesium oxide, and ultrasonicate for 10 minutes to uniformly dissolve magnesium oxide Suspended and dispersed in MDEA aqueous solution to prepare MDEA-MgO composite absorbent.

[0019] In a 50ml glass reactor, the CO 2 For the capture capacity test, 40.5ml of the above-mentioned composite absorbent is loaded into a glass reactor, and the absorption temperature is controlled at 25°C. CO was introduced into the reactor 2 and N 2 , CO 2 The flow rate is 5ml / min, N 2 The flow rate is 45ml / min. CO 2 and N 2 After mixing, it enters the reactor, and the gas reaction product is analyzed by mass spectrometry after being absorbed by the absorbent. Absorbent captures CO 2 The capabilities can be seen in Table 1. The flow chart of the reaction device is attached figure 1 .

Embodiment 3

[0021] Preparation of organic amine-metal oxide composite absorbent: Dissolve 5 g of organic amine N-methyldiethanolamine (MDEA) in 400 ml of water, then add 2 g of basic metal oxide magnesium oxide, stir for 10 minutes, and dissolve magnesium oxide evenly Suspended and dispersed in MDEA aqueous solution to prepare MDEA-MgO composite absorbent.

[0022] In a 50ml glass reactor, the CO 2 For the capture capacity test, 40.5ml of the above-mentioned composite absorbent is loaded into a glass reactor, and the absorption temperature is controlled at 25°C. CO was introduced into the reactor 2 and N 2 , CO 2 The flow rate is 5ml / min, N 2 The flow rate is 45ml / min. CO 2 and N 2 After mixing, it enters the reactor, and the gas reaction product is analyzed by mass spectrometry after being absorbed by the absorbent. Absorbent captures CO 2 The capabilities can be seen in Table 1. The flow chart of the reaction device is attached figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com