Preparation method of metal-organic frame material La-BDC adsorbing CO2 and modified product of metal-organic frame material La-BDC

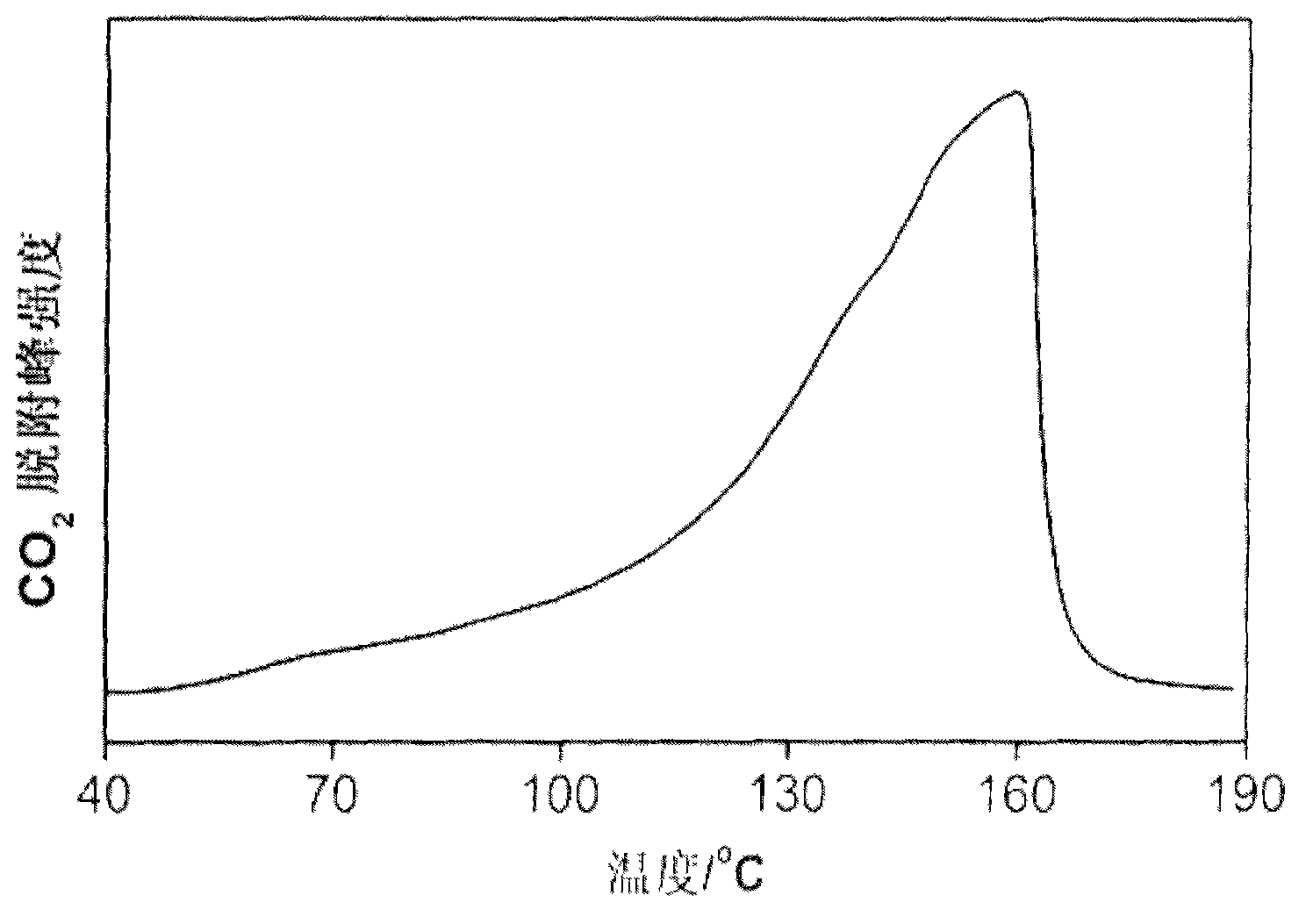

An organic framework and metal technology, applied in the field of preparation of metal-organic framework materials La-BDC and its modified products, can solve the problems of small adsorption amount of metal-organic framework materials, obvious harm to human body, and inability to achieve efficient gas adsorption , achieve good industrial application prospects, large adsorption capacity, and solve the effect of low-pressure adsorption with small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0030] a. Add 3.409g La(NO 3 ) 2 Dissolve in 30ml deionized water, stir and dissolve to form solution A;

[0031] b. Dissolve 0.28g NaOH in 50ml deionized water, after stirring and dissolving, add the calculated amount of 1,4-phthalic acid (H 2 BDC), after vigorously stirring and dissolving, solution B is formed;

[0032] c. At room temperature, add solution A to solution B dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0033] d. At 160°C, the mixed solution of solution A and solution B was crystallized for 24 hours to obtain a solid product;

[0034] e. Wash the solid product obtained in step d with deionized water until the pH of the washing water is close to 7, and then raise the temperature of the solid product washed with deionized water to 180 °C at a heating rate of 5 °C / min in a muffle furnace. ℃ for 6 hours to obtain the metal-organic framework material La-BDC.

preparation example 2

[0036] a. Add 3.409g La(NO 3 ) 2Dissolve in 30ml deionized water, stir and dissolve to form solution A;

[0037] b. Dissolve 0.392g KOH in 50ml deionized water, stir and dissolve, then add the calculated amount of 1,4-phthalic acid (H 2 BDC), after vigorously stirring and dissolving, solution B is formed;

[0038] c. At room temperature, add solution A to solution B dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0039] d. At 170°C, the mixed solution of solution A and solution B was crystallized for 24 hours to obtain a solid product;

[0040] e. Wash the solid product obtained in step d with deionized water until the pH of the washing water is close to 7, and then raise the temperature of the solid product washed with deionized water to 190 °C at a heating rate of 5 °C / min in a muffle furnace. ℃, kept for 5 hours, and the metal-organic framework material La-BDC was obtained.

preparation example 3

[0042] a. Add 3.409g La(NO 3 ) 2 Dissolve in 30ml deionized water, stir and dissolve to form solution A;

[0043] b. Add 0.371g Na 2 CO 3 Dissolve in 50ml deionized water, stir and dissolve, add the calculated amount of 1,4-phthalic acid (H 2 BDC), after vigorously stirring and dissolving, solution B is formed;

[0044] c. At room temperature, add solution A to solution B dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0045] d. At 180°C, the mixed solution of solution A and solution B was crystallized for 18 hours to obtain a solid product;

[0046] e. Wash the solid product obtained in step d with deionized water until the pH of the washing water is close to 7, and then raise the temperature of the solid product washed with deionized water to 190 °C at a heating rate of 5 °C / min in a muffle furnace. The temperature was kept at ℃ for 5 hours, and the metal-organic framework material La-BDC was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com