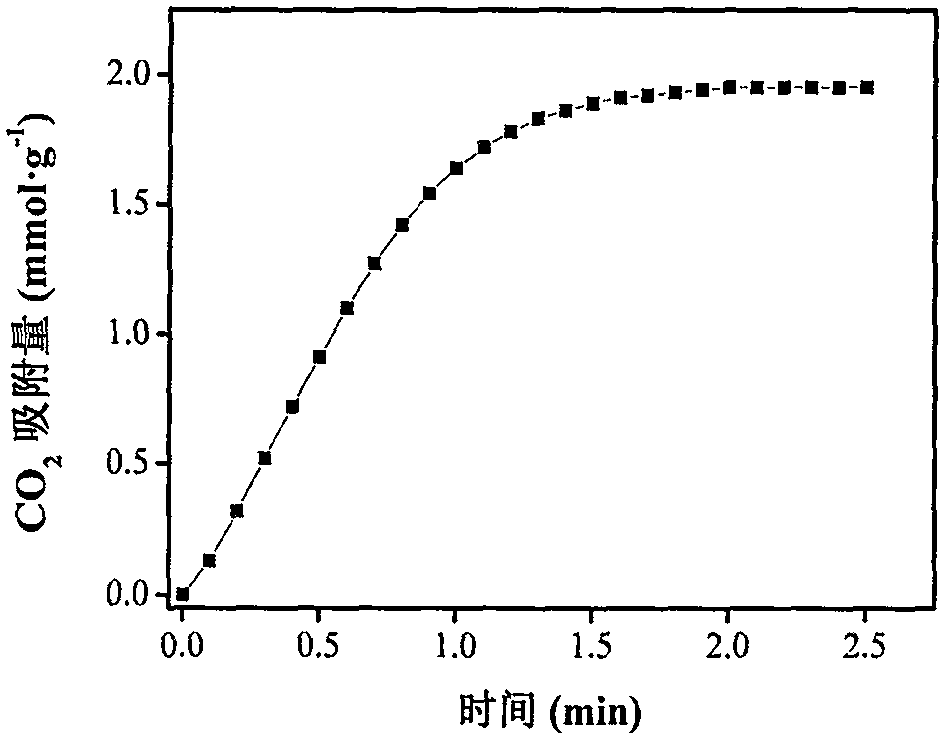

Preparation and modification method of ZrO2 as oxide for adsorbing CO2

A technology of oxides and CO2, applied in chemical instruments and methods, zirconia, separation methods, etc., can solve problems such as high energy consumption, difficult regeneration of amine solution, and high corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0027] a. Dissolve 1.5g polyethylene glycol and 0.9g sodium hydroxide in 80ml deionized water, add 3.22g ZrOCl 2 ·8H 2 O, stirred for 6h to obtain a reaction liquid;

[0028] b. The resulting reaction liquid was hydrothermally treated in a PTFE-lined kettle at 110°C for 24 hours, washed with water, and finally dried in a drying oven at 130°C for 24 hours to obtain the oxide ZrO 2 powder.

preparation example 2

[0030] a. Dissolve 1.5g polyethylene glycol and 0.9g sodium hydroxide in 80ml deionized water, add 2.415g ZrOCl 2 ·8H 2 O, stirred for 5h to obtain a reaction liquid;

[0031] b. The resulting reaction liquid was hydrothermally treated in a PTFE-lined kettle at 110°C for 24 hours, washed with water, and finally dried in a drying oven at 130°C for 24 hours to obtain the oxide ZrO 2 powder.

preparation example 3

[0033] a. Dissolve 1.5g polyethylene glycol and 0.9g sodium hydroxide in 80ml deionized water, add 1.61g ZrOCl 2 ·8H 2 O, stirred for 4h to obtain a reaction liquid;

[0034] b. The resulting reaction liquid was hydrothermally treated in a PTFE-lined kettle at 110°C for 24 hours, washed with water, and finally dried in a drying oven at 130°C for 24 hours to obtain the oxide ZrO 2 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com