an adsorbed co 2 The preparation and modification method of the solid material zr-cn

A solid material and modification technology, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve problems such as low energy consumption, small adsorption capacity, and high adsorption-desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0029] a. Dissolve 8mmol potassium ferrocyanide in 80ml deionized water to form solution A1;

[0030] b. Add 4 mmol of zirconium oxychloride octahydrate to the A1 solution, and stir at 30° C. for 3 h to obtain the first solid product;

[0031] c. washing the obtained first solid product with deionized water until the solution is neutral;

[0032] d. The washed first solid product was dried at 30° C. for 12 hours, and then dried in a vacuum oven at 80° C. for 6 hours to obtain the solid material Zr-CN.

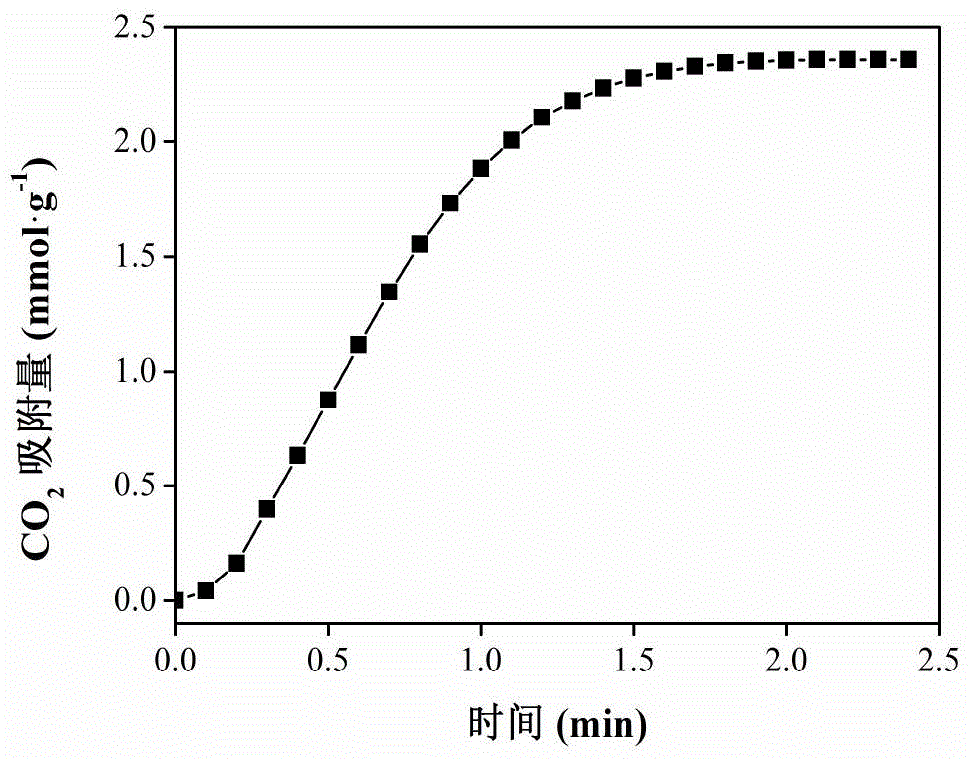

[0033] According to the obtained solid material Zr-CN of embodiment 1 to CO 2 The curve of the adsorption capacity with time is shown in the appendix figure 1 As shown, it can be seen from the figure that the Zr-CN to CO 2 The adsorption increases with time, and the maximum adsorption capacity is 2.35mmol·g -1 .

preparation example 2

[0035] a. Dissolve 8mmol potassium ferrocyanide in 80ml deionized water to form solution A1;

[0036] b. Add 8 mmol of zirconium oxychloride octahydrate to the A1 solution, and stir at 30°C for 4 hours to obtain the first solid product;

[0037] c. washing the obtained first solid product with deionized water until the solution is neutral;

[0038] d. The washed first solid product was dried at 40° C. for 18 hours, and then dried in a vacuum oven at 80° C. for 7 hours to obtain the solid material Zr-CN.

preparation example 3

[0040] a. Dissolve 8mmol potassium ferrocyanide in 80ml deionized water to form solution A1;

[0041] b. Add 12 mmol of zirconium oxychloride octahydrate to the A1 solution, and stir at 30° C. for 5 h to obtain the first solid product;

[0042] c. washing the obtained first solid product with deionized water until the solution is neutral;

[0043] d. The washed first solid product was dried at 50° C. for 24 hours, and then dried in a vacuum oven at 80° C. for 8 hours to obtain the solid material Zr-CN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com