Shaking table for pre-concentrating vanadium by performing ore dressing on vanadium-containing stone coal

A pre-concentration, vanadium stone technology, applied in the field of shaking table, can solve the problems of poor sorting effect, low recovery rate, low concentrate grade, etc., and achieve good sorting effect, high concentrate grade, and associated minerals. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

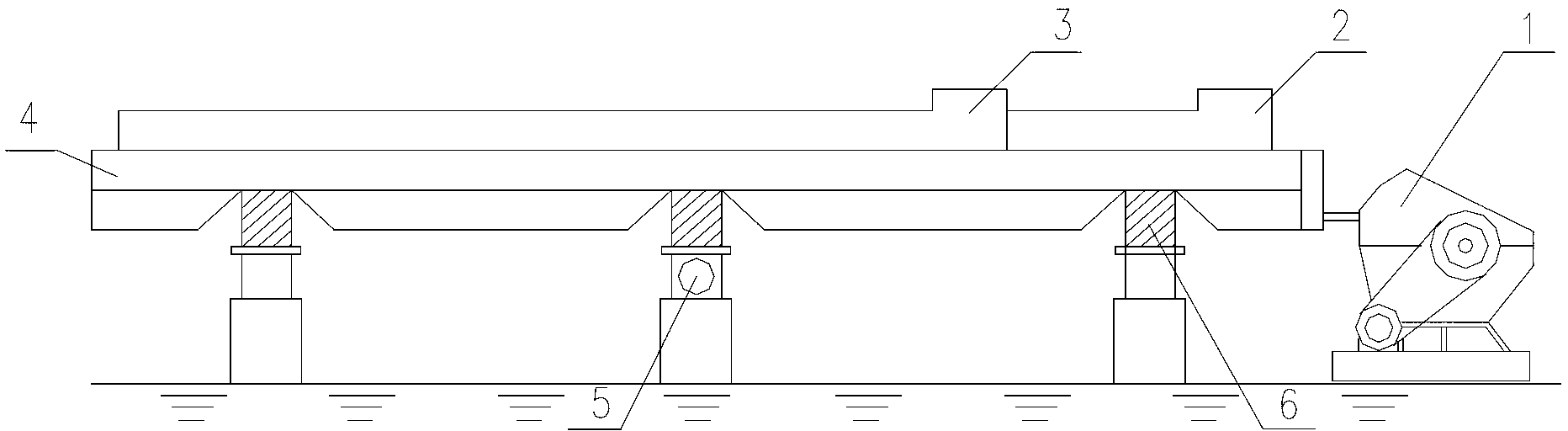

[0028] A shaking bed used for vanadium-containing stone coal beneficiation to pre-enrich vanadium. like figure 1 As shown, the shaker consists of a bed surface 4 , a support mechanism 6 , a slope adjustment mechanism 5 and a transmission mechanism 1 . The bed surface 4 is installed on the supporting mechanism 6, there are three supporting mechanisms 6, and the supporting mechanisms 6 are parallel to each other.

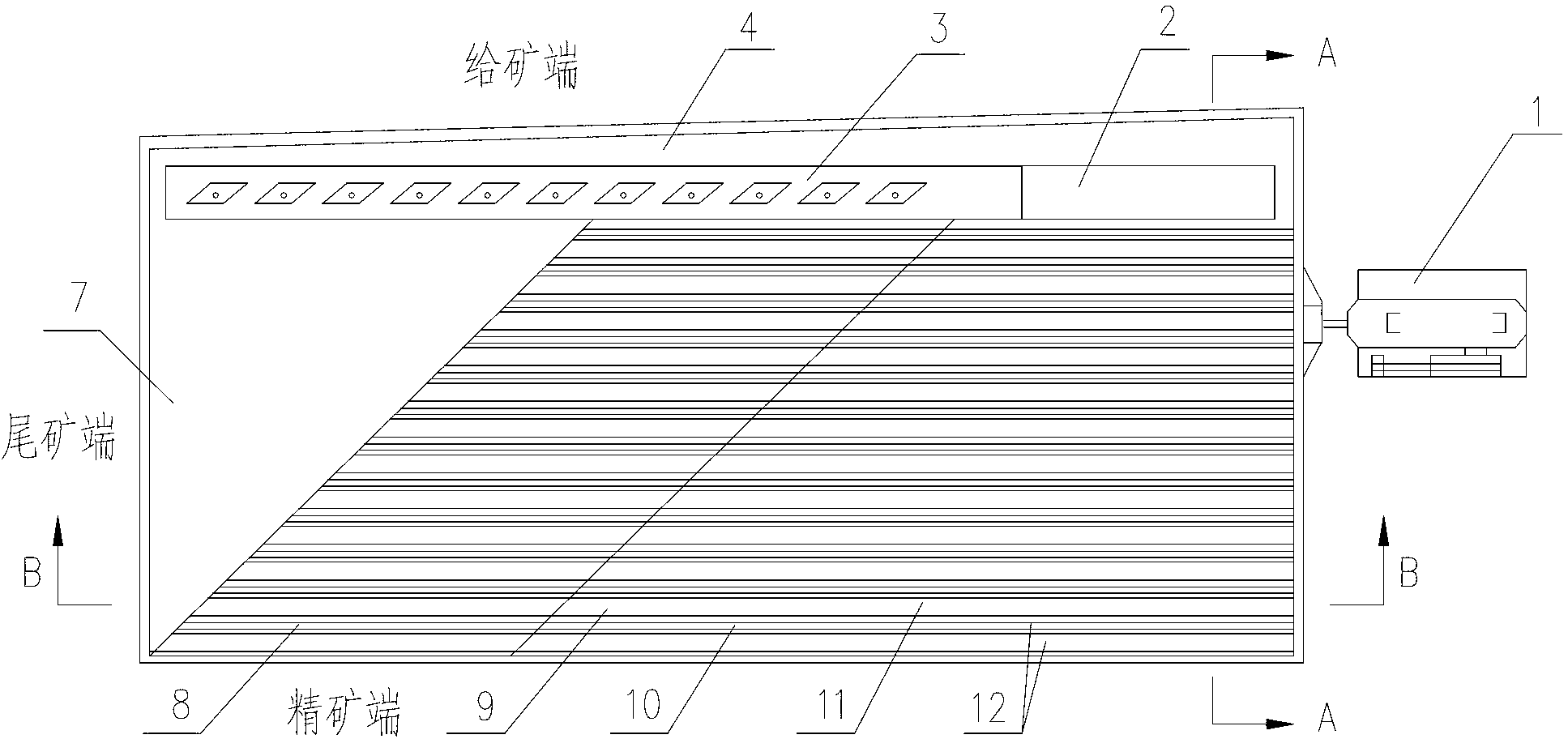

[0029] The bed surface 4 of this embodiment is as follows figure 2 As shown, it includes a roughing table 9, a checking table 8 and a sweeping table 7. On the bed surface 4, one end of the ore feeding groove 2 and the water feeding groove 3 is the ore feeding end, the end facing the ore feeding end is the concentrate end, and the end facing the transmission mechanism is the tailing end.

[0030] like figure 2 As shown, the sweeping bed 7 is located at the tailings end of the bed 4, the outline of the sweeping bed 7 is a right triangle, and the hypotenuse of the ...

Embodiment 2

[0036] A shaking bed used for vanadium-containing stone coal beneficiation to pre-enrich vanadium. Except the following technical parameters, all the other are the same as in Example 1:

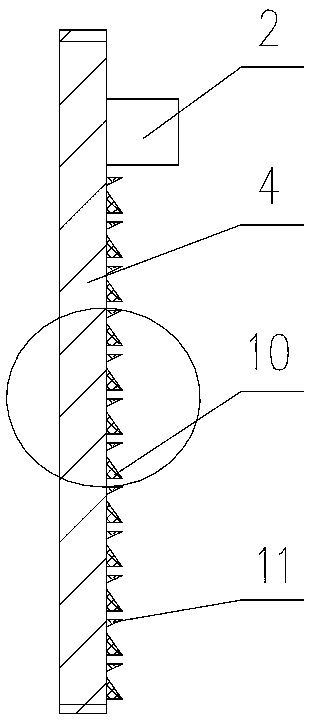

[0037]Both the roughing bed surface 9 and the reselecting bed surface 8 are equipped with 10-11 bed strip groups 12; the pinch-out angle of the bed surface 4 is 40-50 o The slope of the re-selected bed surface 8 is 1-1.5%; the slope of the steep slope bed 11 is 200-240%; the slope of the gentle slope 10 is 45-55%; the roughness of the sweeping bed 7 is 75-85 μm ; The roughness of the roughing bed surface 9 and the re-selecting bed surface 8 is 50-70 μm.

Embodiment 3

[0039] The utility model relates to a shaker for pre-enrichment of vanadium in vanadium-containing stone coal beneficiation. Except following technical parameter, all the other are with embodiment 1:

[0040] Both the rough selection bed surface 9 and the double selection bed surface 8 are equipped with 13~20 bed strip groups 12; the pinch-out angle of the bed surface 4 is 35~45° o The slope of the re-selected bed surface 8 is 1.5-2%; the slope of the steep slope bed 11 is 235-275%; the slope of the gentle slope 10 is 50-58%; the roughness of the sweeping bed 7 is 80-90 μm ; The roughness of the roughing bed surface 9 and the re-selecting bed surface 8 is 55-75 μm.

[0041] This specific embodiment is used in the process of vanadium-containing stone coal beneficiation and pre-enrichment of vanadium, so that the horizontal water flow will arouse a high-intensity eddy current when the roughing bed surface 9 crosses the steep slope bed strip 11, forming a relatively large ascend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com