Safety protection device for special iron core ejector rod welding machine

A safety protection device, welding machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of poor safety performance, easy to hurt operators, etc., to achieve improved safety performance, ingenious structural design, avoidance of safety effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

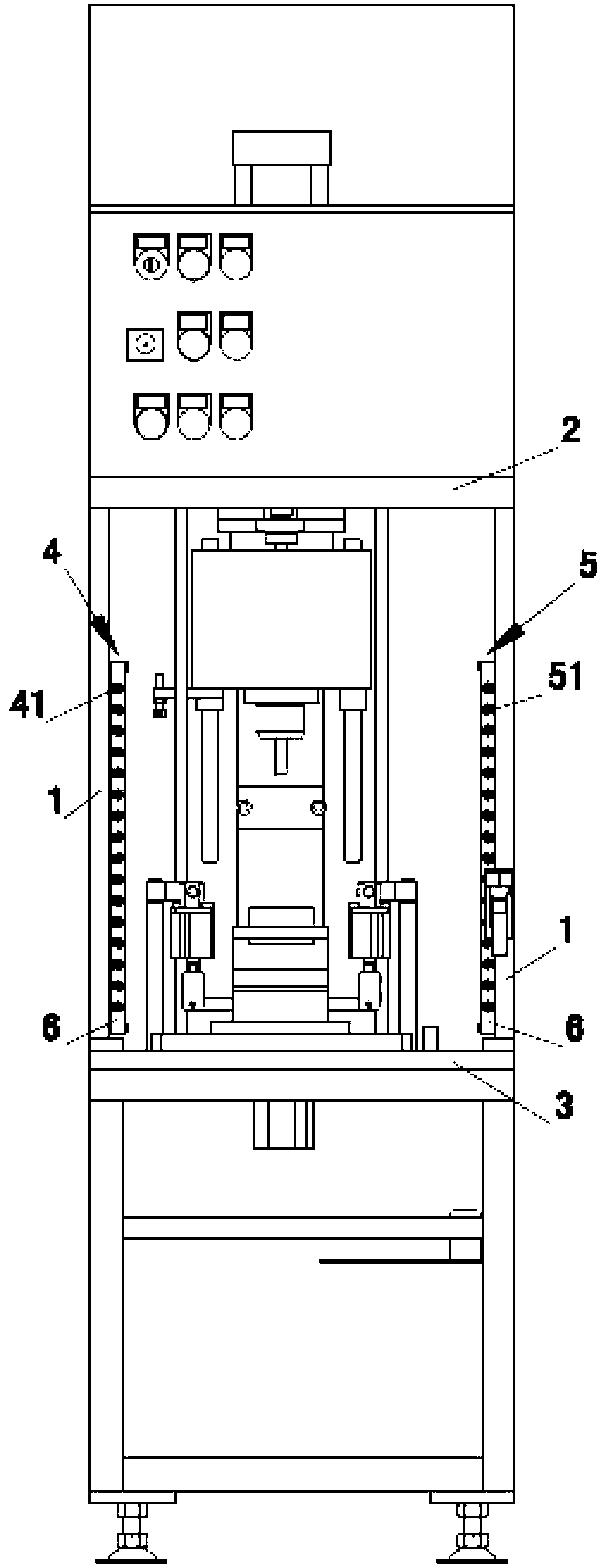

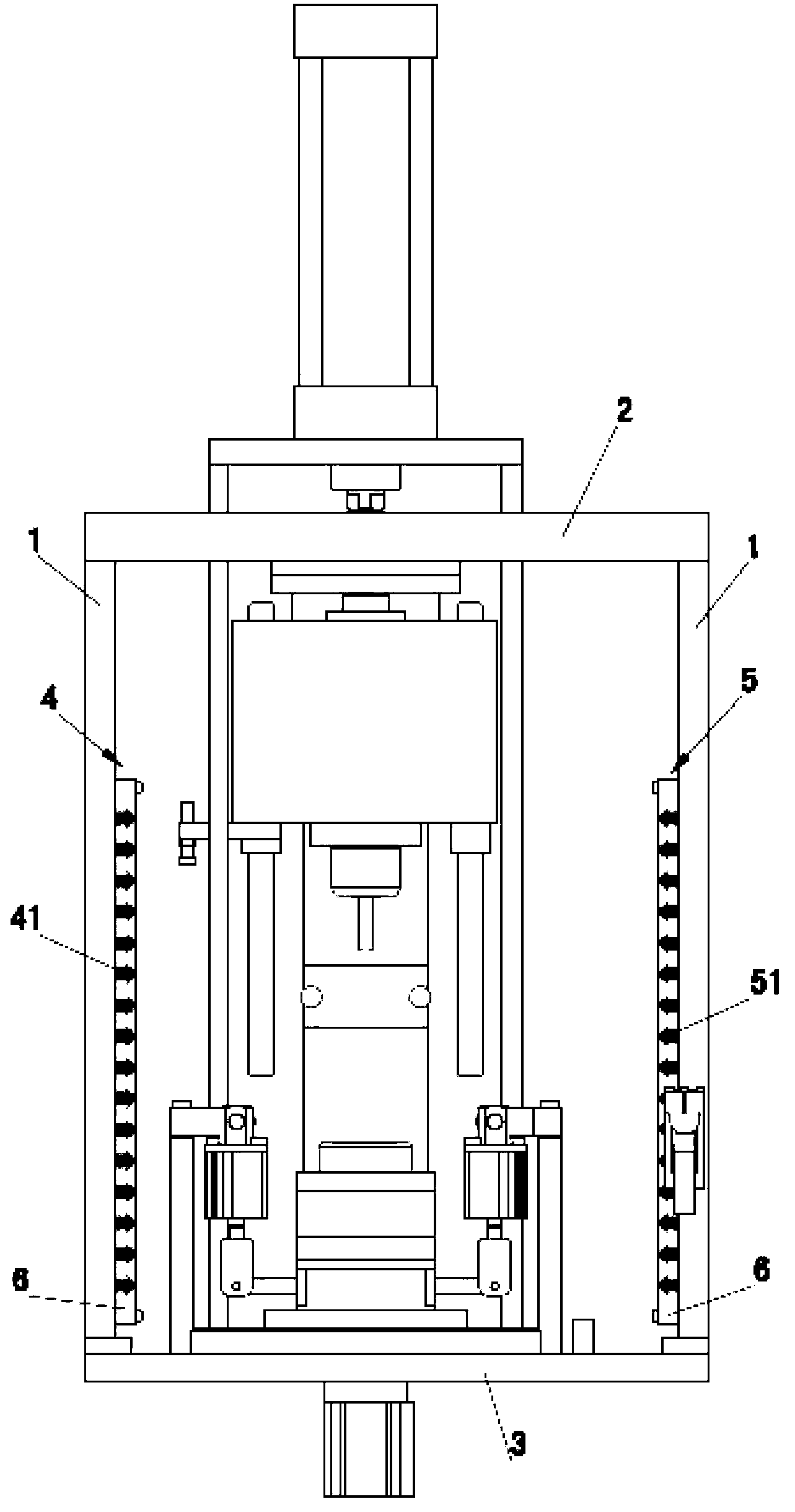

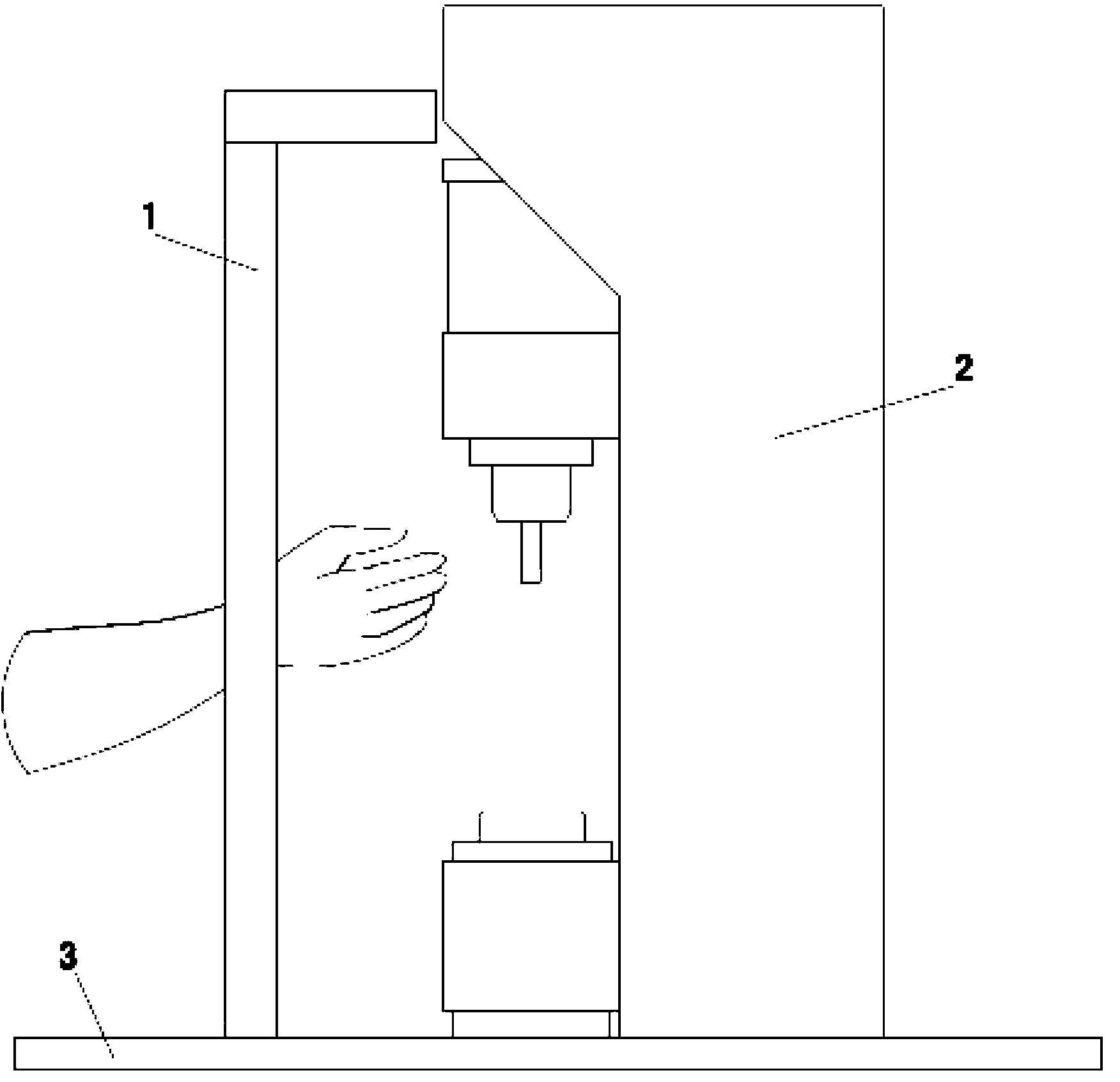

[0018] like Figure 1~3 The present invention will be further described below in conjunction with the accompanying drawings and embodiments: a safety protection device for a special welding machine for iron core mandrels, the safety protection device includes a safety light curtain and a light curtain bracket 1, and the light curtain bracket 1 There are two, which are symmetrically arranged on both sides in front of the workbench 3 of the welding machine frame 2. The safety light curtain is arranged on the light curtain support 1 and is connected with the welding head of the welding machine.

[0019] The safety light curtain includes a light emitter 4 and a light receiver 5, the light emitter 4 is arranged on a light curtain support 1, and the light receiver 5 is arranged on another light curtain support 1 opposite to the light curtain support 1 , and make the light receiver 5 opposite to the light emitter 4 .

[0020] The light emitter 4 includes a strip-shaped plate 6 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com