Carbonized wood production process

A production process, carbonized wood technology, applied in the direction of charcoal burning/combustion, etc., can solve the problems of high cost, low utilization rate, unfavorable promotion, etc., and achieve the effect of low cost of use, simple equipment, and simple carbonization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

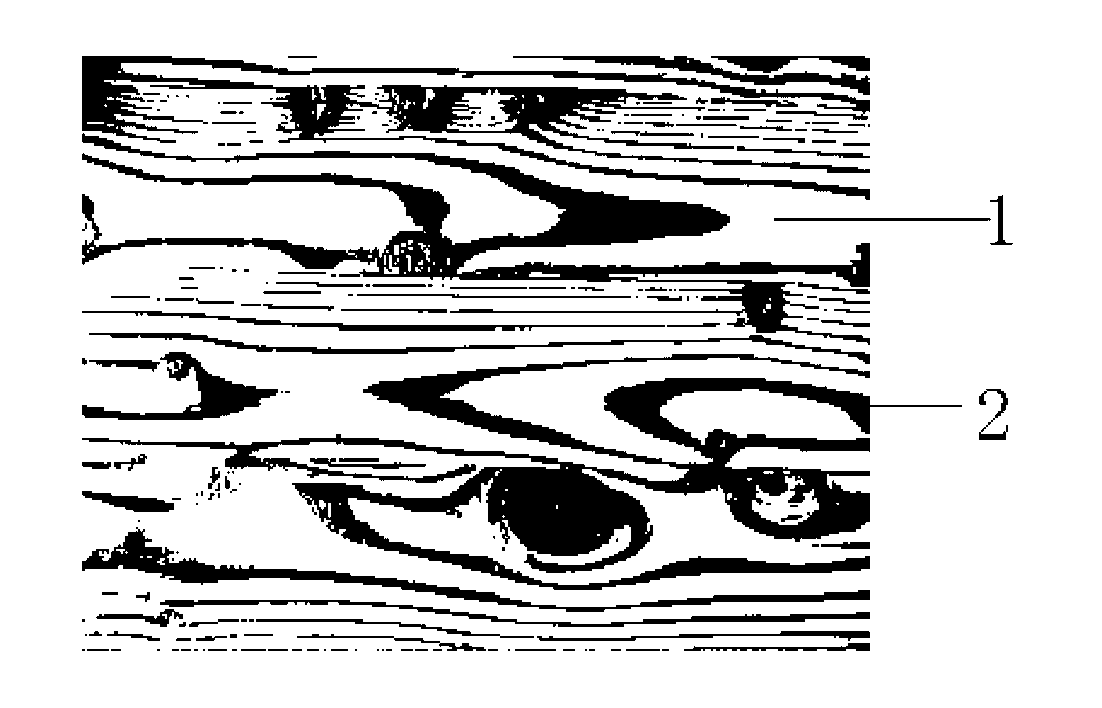

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Treat the wood into the shape and size used for decoration or furniture. Use an oxygen flame spray gun to spray fire carbonization on the wood surface. This carbonization is shallow carbonization on the wood surface. After carbonization, the soft part of the wood surface is severely carbonized and the texture The hard part has a low degree of carbonization. Use sandpaper or a sander to lightly sand the surface of the carbonized wood. The severely carbonized area will show a depression 1 after grinding, while the hard part of the wood has a low degree of carbonization and will be convex relative to the depression 1 after grinding. If the wood surface is protruding 2, the natural texture of the wood surface is preserved, and the wood surface presents a three-dimensional texture. which is:

[0017] A manufacturing process of carbonized wood, comprising the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com