Mold stripping and lifting tool device for drum

The technology of a spreader and a fixing device, which is applied in the field of the spreader device of the mixing drum, can solve the problems of unsuitability to production needs, wire rope loss, etc., and achieve the effects of convenient control, large usable space, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

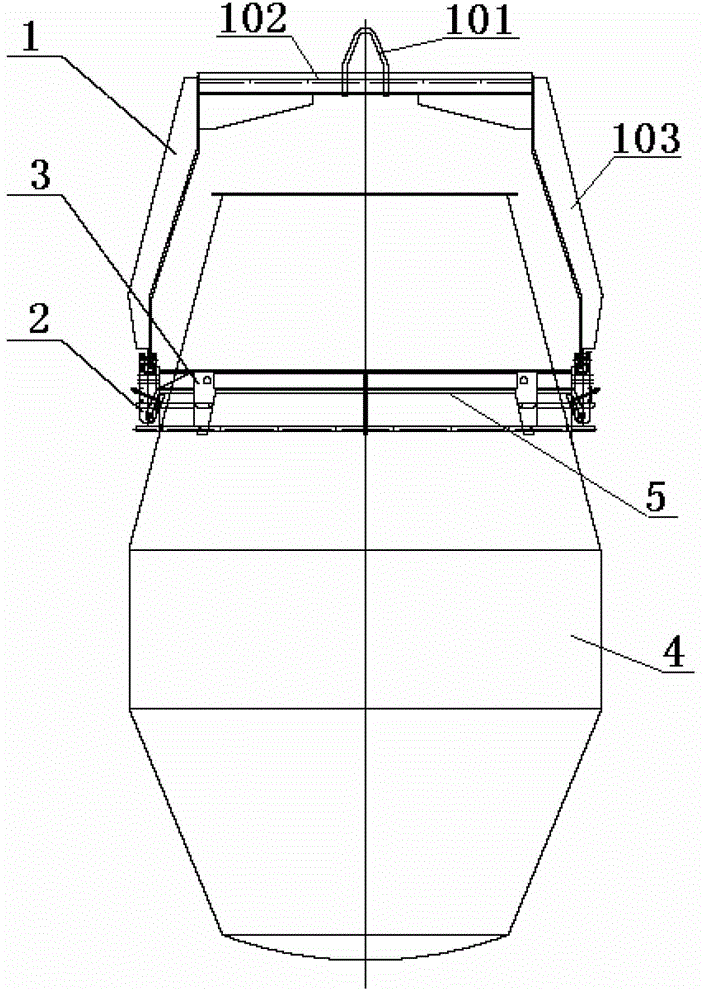

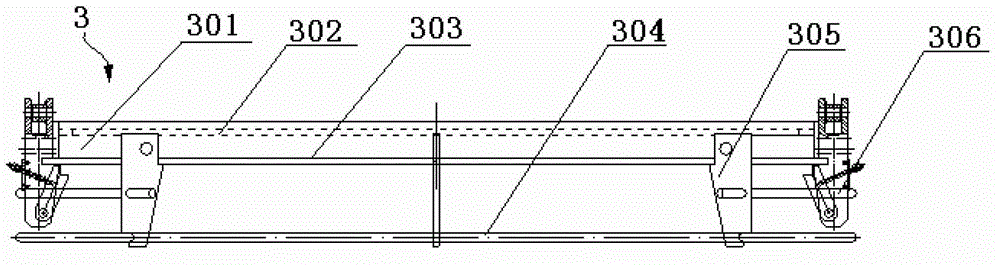

[0030] Such as figure 1 As shown, the mixing cylinder ejection spreader device of the present invention includes a boom 1, a bolt fixing device 2 and a main body structure 3;

[0031] Such as figure 1 , Figure 5 As shown, the boom 1 is a gantry boom, and a suspension ring 101 is provided at the center of its upper part; The suspension ring 101 is fixedly arranged at the center of the shoulder pole 102 . The lower ends of the brackets on the left and right sides of the boom are respectively welded with bushings 104 , the bushings 104 at the lower ends of the boom are inserted into the upper opening of the base 201 , and are fixedly connected with the base 104 through the second pin 8 .

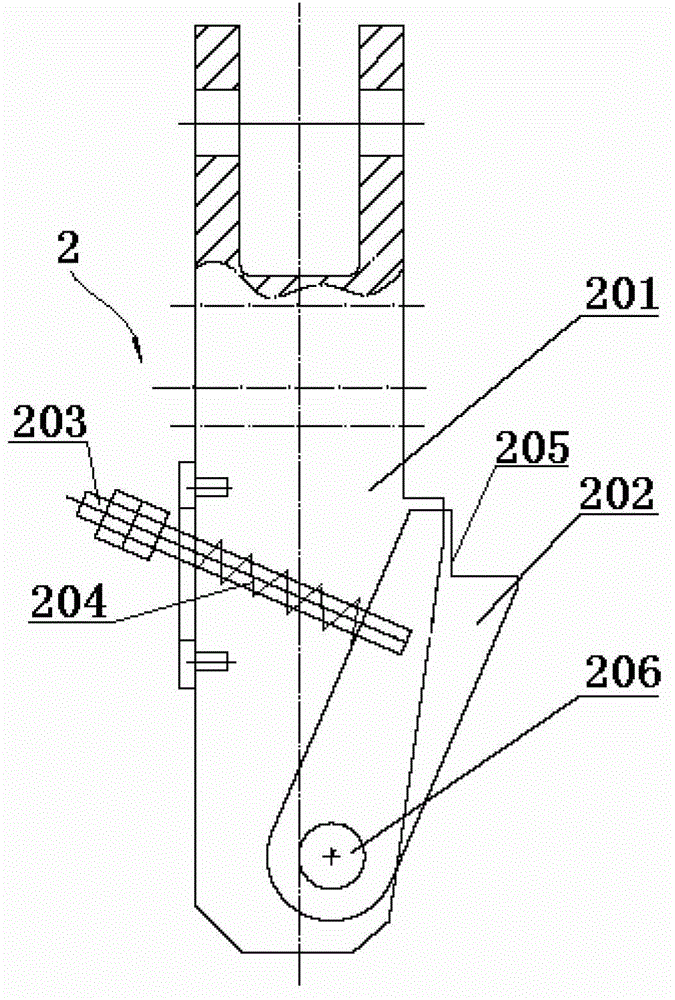

[0032] Such as figure 2 As shown, the locking tongue fixing device 2 is symmetrically connected to the lower ends of both sides of the boom respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com