Combined double-vortex efficient muddy water purification device

A purification device and double-swirl technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve high operating costs, large floor space, unfavorable energy conservation and environmental protection, etc. problems, to achieve the effect of improving work efficiency, saving space, and excellent water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The combined dual-swirl high-efficiency turbid water purification device of the present invention is a new design based on the structure of the applicant's original high-efficiency combined water purifier (Chinese patent ZL2011201302369).

[0029] The basic structure of the combined double-swirl high-efficiency turbid water purification device of the present invention is:

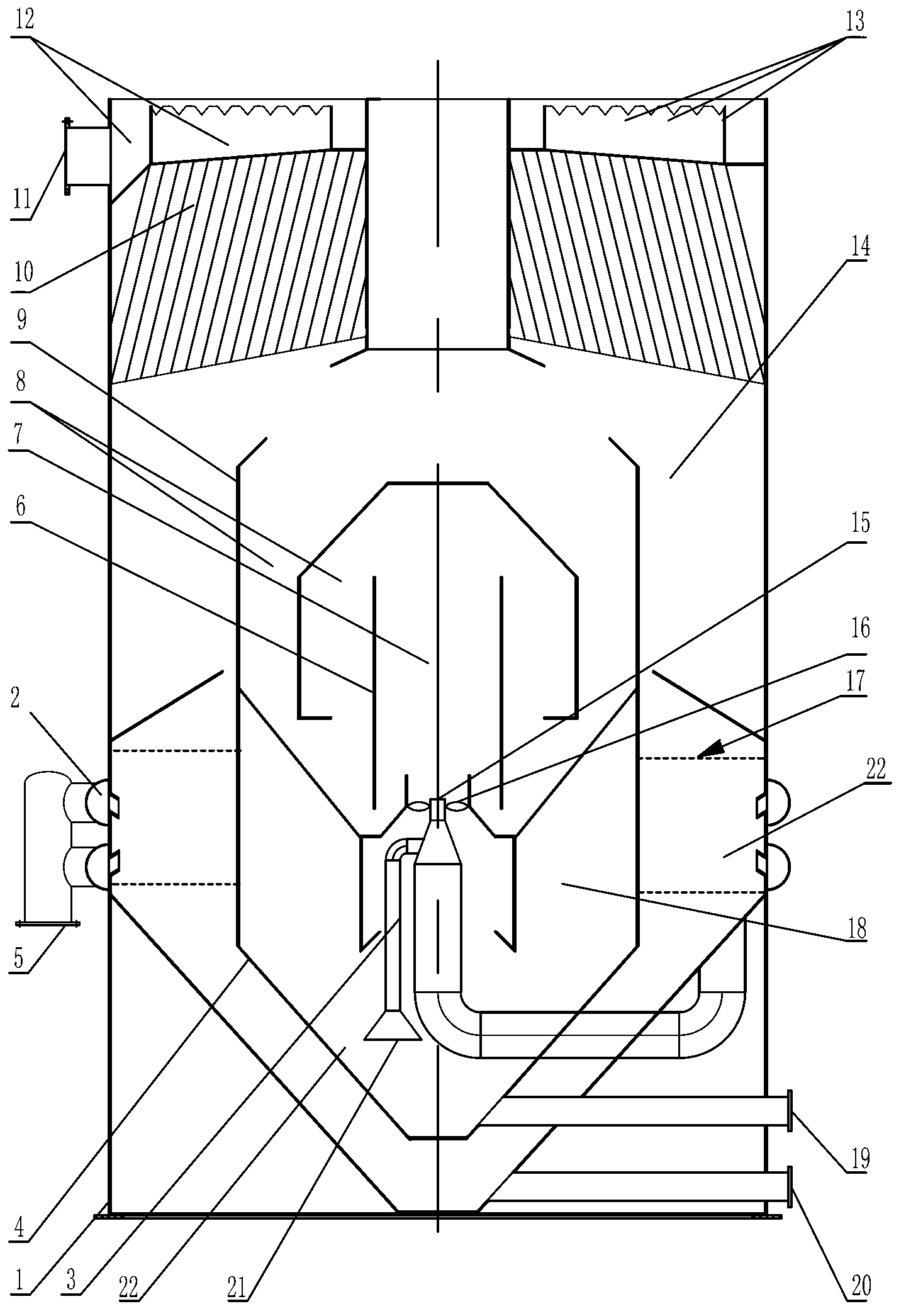

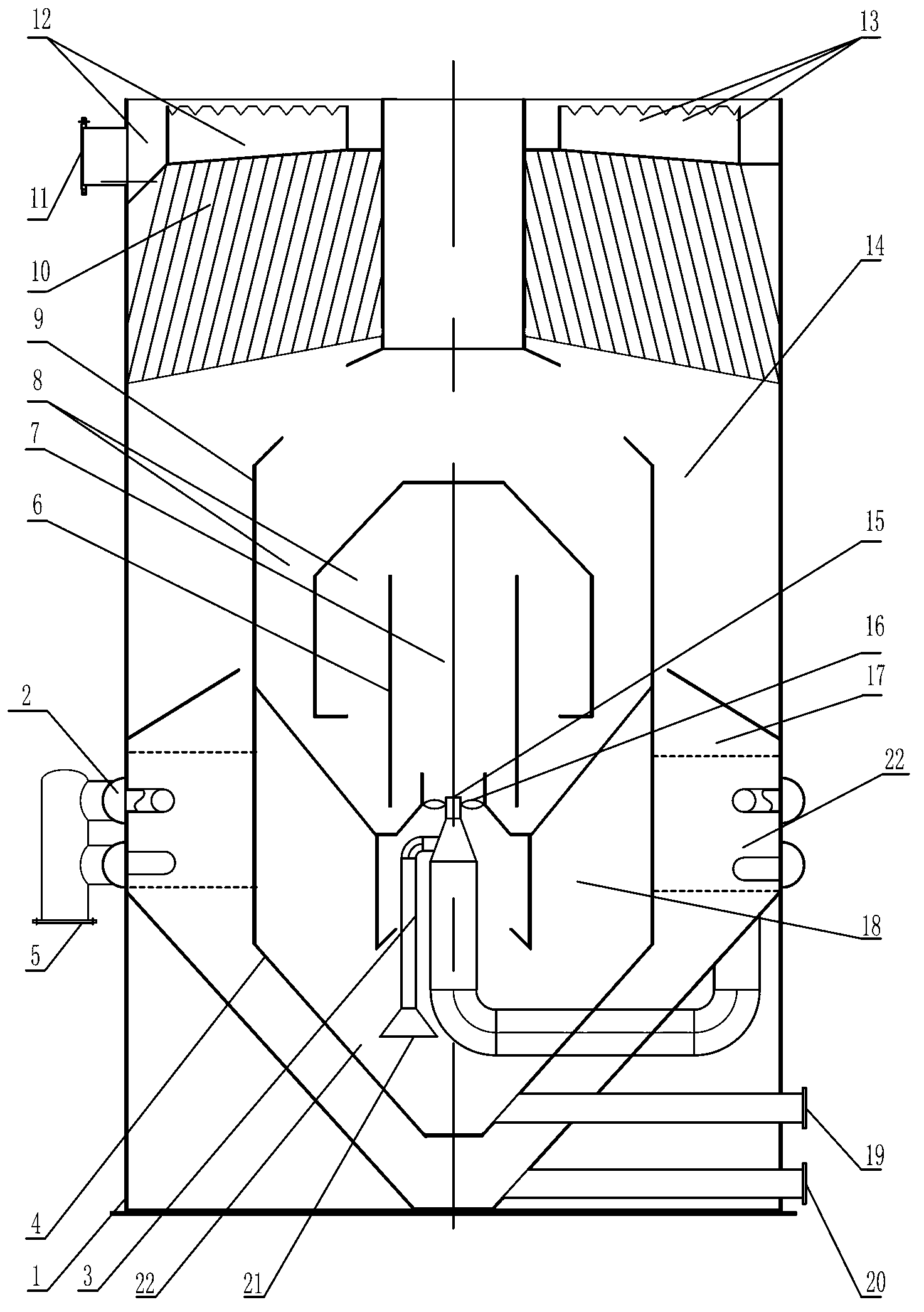

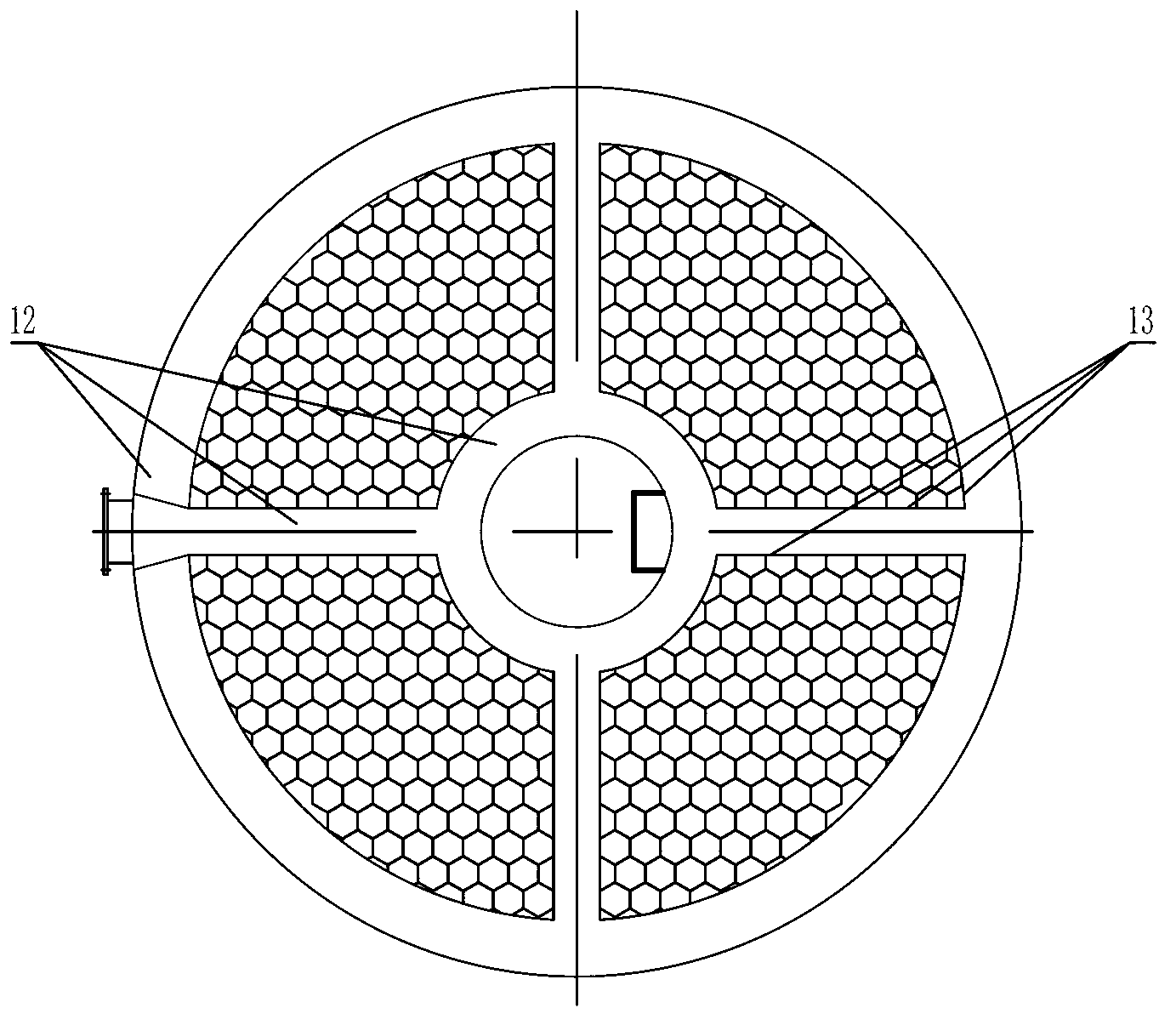

[0030] Such as Figure 1 to Figure 4 As shown, the present invention's combined double-swirl high-efficiency turbid water purification device is a vertical independent tank body 1, which is provided with a water inlet 5, a water outlet 11, a mud discharge port 19 and a sludge discharge port 20. In this purification device tank From bottom to top, there are sludge accumulation area, mixing area, propulsion reaction area, clarification and sedimentation area, inclined tube sedimentation area and water outlet unit.

[0031] A sludge discharge port 20 and a sludge discharge port 19 are respectively open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com