Novel method for extraction of tyrosine from hairs through one-step refining process

A refining method and tyrosine technology, applied in the field of tyrosine extraction, can solve the problems of polluting the environment, decreasing the yield of cystine, and affecting the production environment of the workshop, so as to reduce environmental pollution, shorten the production cycle, and increase the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

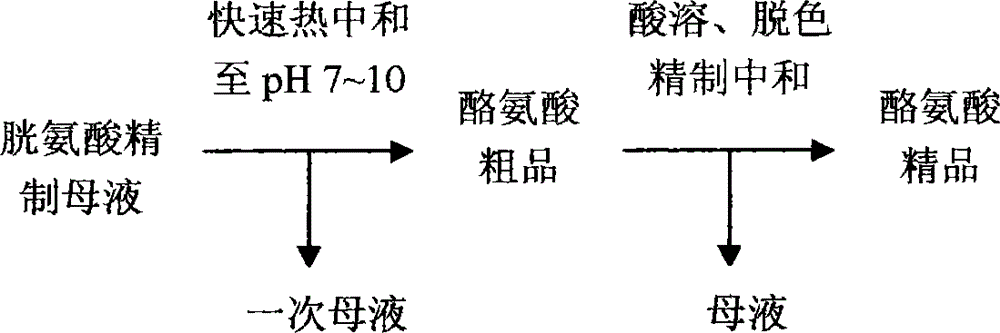

[0023] Take 2.5L of the refined mother liquor for extracting cystine from pig hair (equivalent to 1000g pig hair), heat it up to 60°C, quickly neutralize it with concentrated ammonia water to pH8.5 under stirring, and filter while it is hot. Precipitated as crude tyrosine. The filtrate is the primary mother liquor, which can be counter-neutralized to about pH 5 with hydrochloric acid, cooled and settled for one day, and filtered to recover cystine. Transfer the crude tyrosine into a beaker, add dilute hydrochloric acid until the crude product is completely dissolved, control the volume at 400mL, heat to 70-80°C, add 10g of activated carbon, stir for 0.5-2h to decolorize, filter and wash to obtain a decolorized solution. The volume is controlled at 500mL. Put the decolorizing solution in a beaker, slowly neutralize it with dilute ammonia water to pH 1.8 at 50-80°C, cool to 40°C, filter and wash to obtain 16.8g of tyrosine product. The light transmittance of the product is 95....

Embodiment 2

[0025] Take 2L of refined mother liquor (equivalent to 1000g chicken feathers) for extracting cystine from chicken feathers, heat up to 60°C, quickly neutralize to pH9.0 with concentrated ammonia water under stirring, and filter while hot. Precipitated as crude tyrosine. The filtrate is the primary mother liquor, which can be counter-neutralized to about pH 5 with hydrochloric acid, cooled and settled for one day, and filtered to recover cystine. Transfer the crude tyrosine into a beaker, add dilute hydrochloric acid until the crude product is completely dissolved, control the volume at 800mL, heat to 70-80°C, add 10g of activated carbon, stir for 0.5-2 hours to decolorize, filter, and wash to obtain a decolorized solution. The volume is controlled at 1000mL. Put the decolorizing solution in a beaker, slowly neutralize it with dilute ammonia water to pH 2.0 at 50-80°C, cool to 40°C, filter and wash to obtain 24.3g of finished tyrosine. The light transmittance of the product ...

Embodiment 3

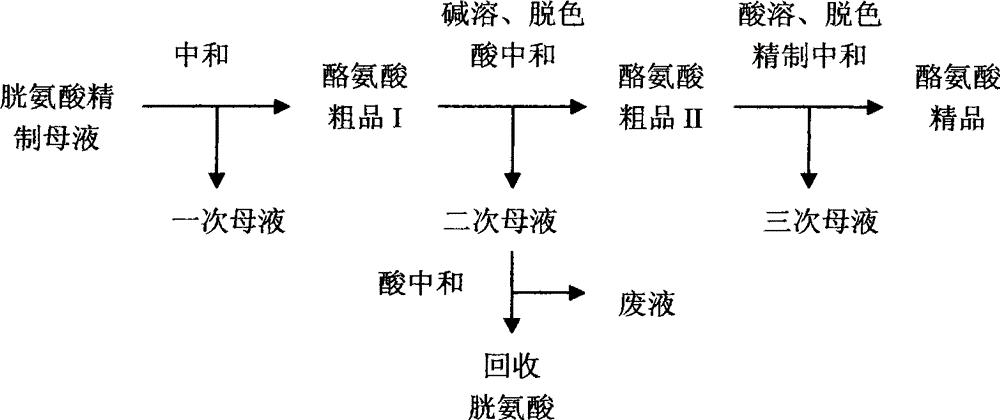

[0026] Embodiment 3 (comparative example)

[0027] Take 2.5 L of refined mother liquor (equivalent to 1000 g of pig hair) for extracting cystine from pig hair, neutralize it with concentrated ammonia water to pH 4.8, let it settle for two days, and filter. The filtrate is the primary mother liquor, and the precipitate is the crude tyrosine I. Transfer the crude tyrosine I into a beaker, add 200mL of water, raise the temperature to 60°C, add 30% NaOH solution at the same time until the crude product dissolves, control the volume at 300mL, add 5g of activated carbon, and stir at 50-60°C for 0.5 ~2h, filter and wash. Put the decolorized solution in a beaker, slowly neutralize it to pH9.0 with 6mol / L hydrochloric acid at 50-60°C, and filter. The precipitate is the crude tyrosine II, and the filtrate is the secondary mother liquor, which can be further neutralized with hydrochloric acid to about pH5, cooled and settled for one day, and filtered to obtain cystine. Transfer the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com