Energy-saving environment-friendly mold releasing agent for production of aerated concrete

An energy-saving, environment-friendly, mold-releasing technology, applied in ceramic molding machines, manufacturing tools, lubricating compositions, etc., can solve the problems of reducing air quality in workshops, cracking of aerated concrete walls, and falling off of veneer, reducing production cost, realize waste utilization, and improve the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

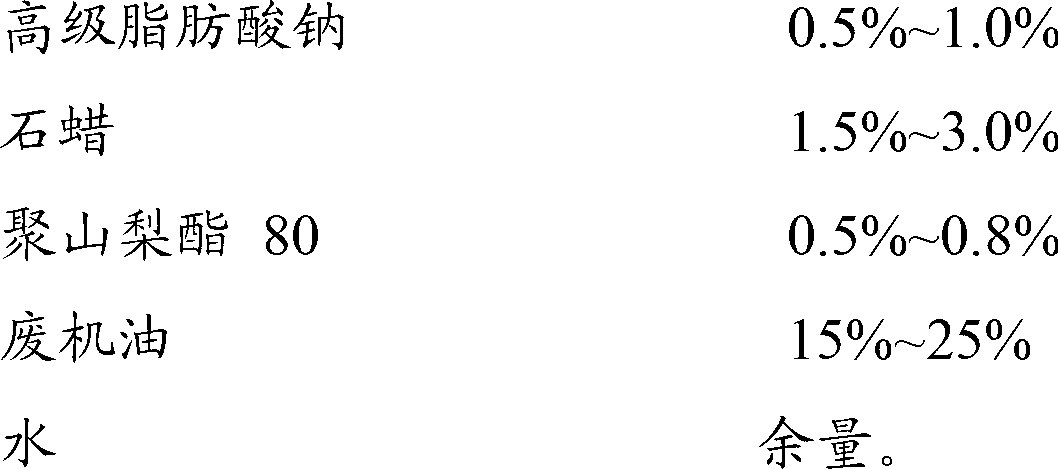

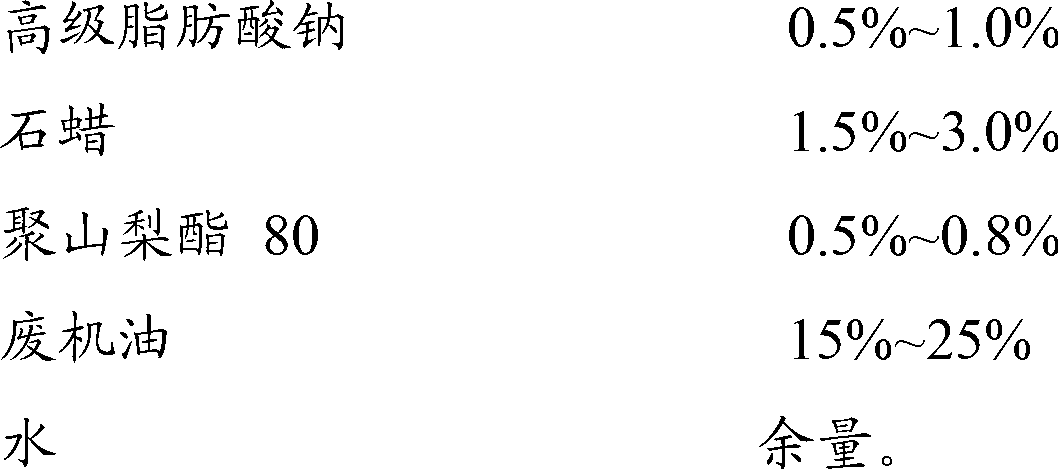

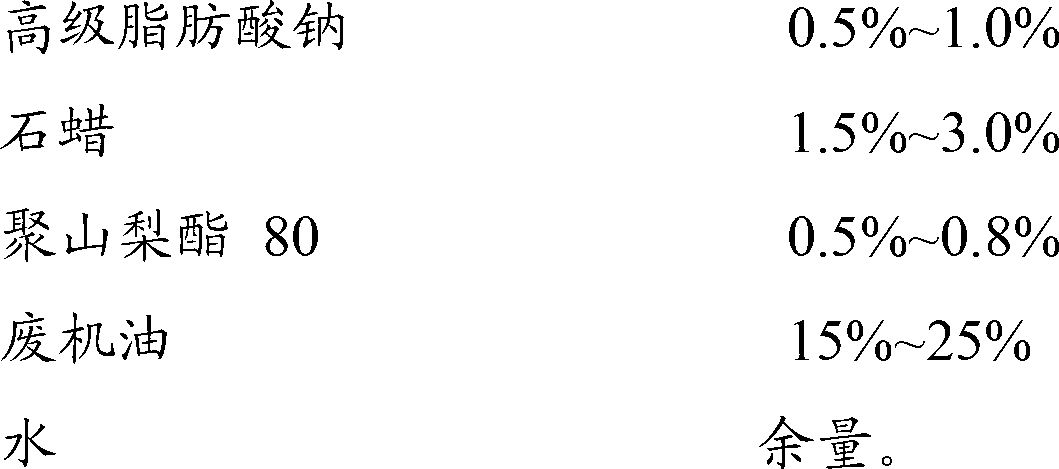

[0017] Under high-speed stirring at 70-100°C, add 0.5 kg of higher fatty acid sodium, 1.5 kg of paraffin, 0.5 kg of polysorbate 80, and 15 kg of waste engine oil to 82.5 kg of water; and add an appropriate amount of preservatives and stabilizers at high speed After stirring for 3 minutes, it becomes a light yellow emulsion.

Embodiment 2

[0019] Under high-speed stirring at 70~100°C, add 1 kg of higher fatty acid sodium, 3 kg of paraffin, 0.8 kg of polysorbate 80, and 25 kg of waste engine oil to 70.2 kg of water; and add an appropriate amount of preservatives and stabilizers at high speed After stirring for 3 minutes, it becomes a light yellow emulsion.

Embodiment 3

[0021] Under high-speed stirring at 70-100°C, add 0.7 kg of higher fatty acid sodium, 2 kg of paraffin, 0.7 kg of polysorbate 80, and 20 kg of waste engine oil to 76.3 kg of water; and add an appropriate amount of preservatives and stabilizers at high speed After stirring for 3 minutes, it becomes a light yellow emulsion.

[0022] The present invention has the following characteristics:

[0023] 1. High efficiency: firstly, the present invention has the characteristics of erosion resistance and autoclave resistance, and both the scoured surface and the autoclaved curing surface of the mold can be completely demoulded during the pouring process; secondly, it solves the problem of aerated concrete walls caused by oily blocks Serious engineering problems such as body cracking, hollowing, and peeling of the finish layer have been eliminated, and the product qualification rate has been improved.

[0024] 2. Environmental protection and energy saving: the main component of the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com