Method for synthesizing ester by using cutinase

A cutinase and reaction system technology, applied in the field of enzyme engineering, can solve the problems of high enzyme addition and low conversion rate of long-chain ester synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this example, the cutinase Tfu_0883 derived from Thermobifida fusca was used to catalyze the reaction.

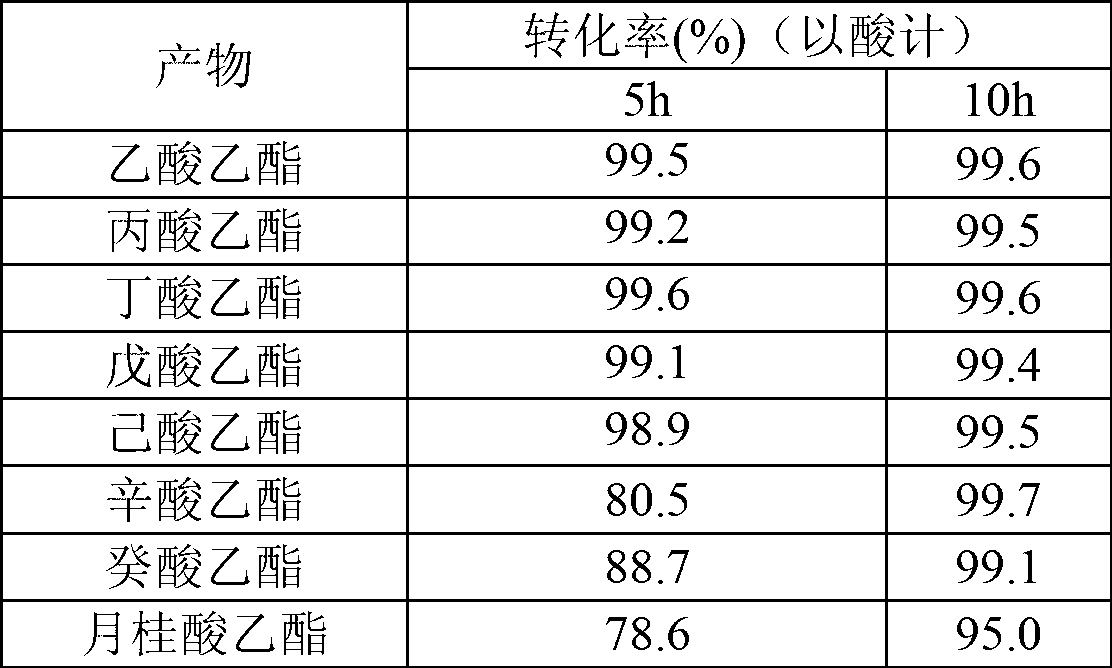

[0016] Organic reagents and substrate acids and alcohols are used for ester synthesis after removing water with 4A molecular sieve. Reaction conditions: 0.1M acid, 0.2M alcohol, 0.03% water added, 50°C, 150rpm, enzyme 30U / ml, reaction solvent isooctane, the specific results are shown in Table 1 and Table 2.

[0017] Table 1

[0018]

[0019]

[0020] Table 2

[0021]

Embodiment 2

[0023] In this example, the cutinase Tfu_0882 derived from Thermobifida fusca was used to catalyze the reaction.

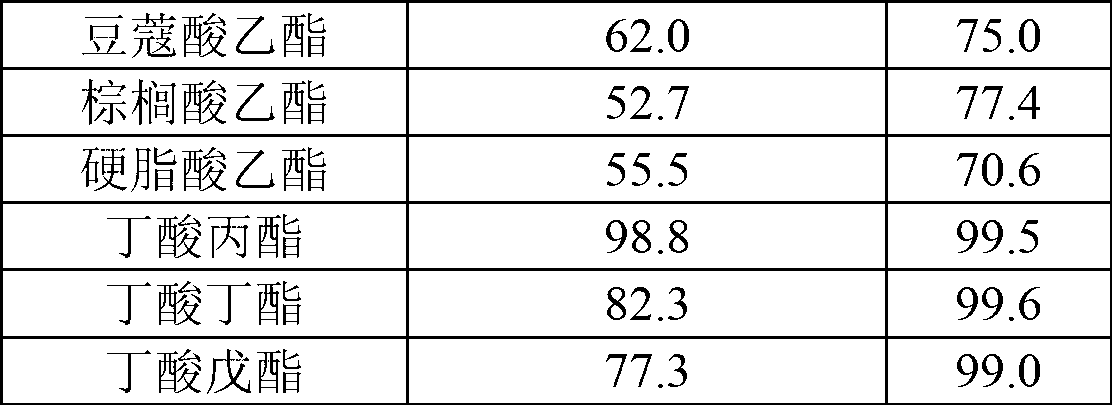

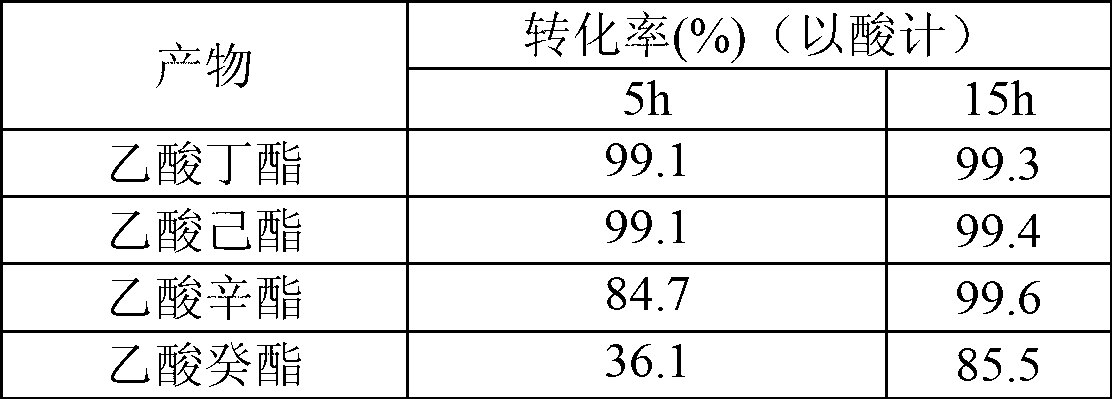

[0024] Reaction conditions: 0.15M acid, 0.3M alcohol, 0.05% water addition, 50°C, 150rpm, enzyme 40U / ml, reaction solvent isooctane, the specific results are shown in Table 3 and Table 4.

[0025] table 3

[0026]

[0027] Table 4

[0028]

Embodiment 3

[0030] In this example, the cutinase Tfu_0883 derived from Thermobifda fusca was used to catalyze the reaction.

[0031] Reaction conditions: 0.5M acid, 0.5M alcohol, 0.08% water added, 50°C, 150rpm, enzyme 60U / ml, reaction solvent isooctane. After reacting for 5h and 15h, the conversion rates of propyl butyrate were 92.8% and 91.5%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com