Continuous hot-dip galvanized centrifugal cyclone slag removal device

A hot-dip aluminum and aluminum-zinc coating technology, which is applied in the hot-dip coating process, coating, metal material coating process, etc., can solve the problems of affecting the production efficiency of the unit, the adverse effect of the coating formability, and uneven spangles, etc., to achieve Excellent social and economic benefits, solve the problem of slag removal, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Introduce this embodiment in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementation example.

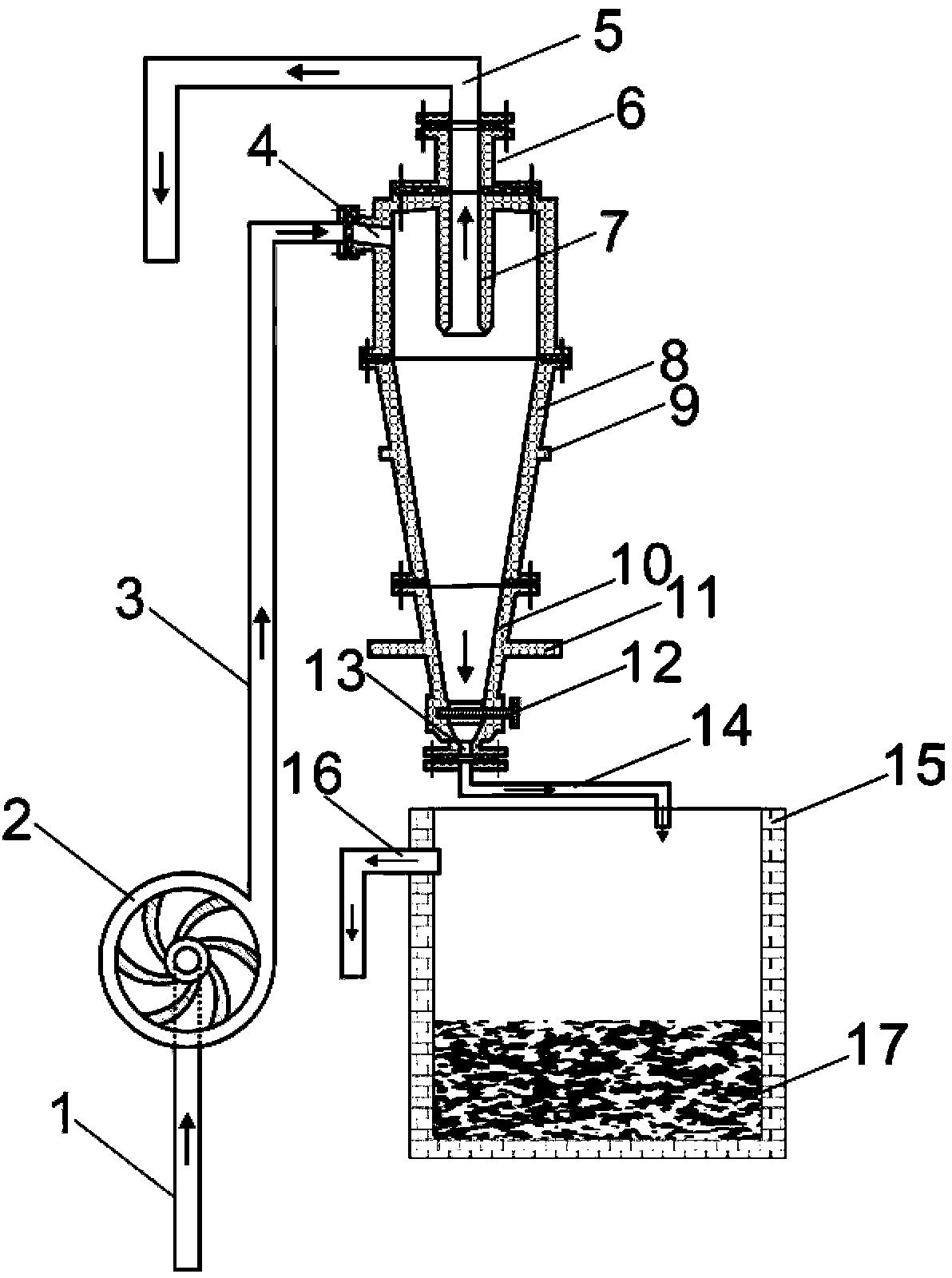

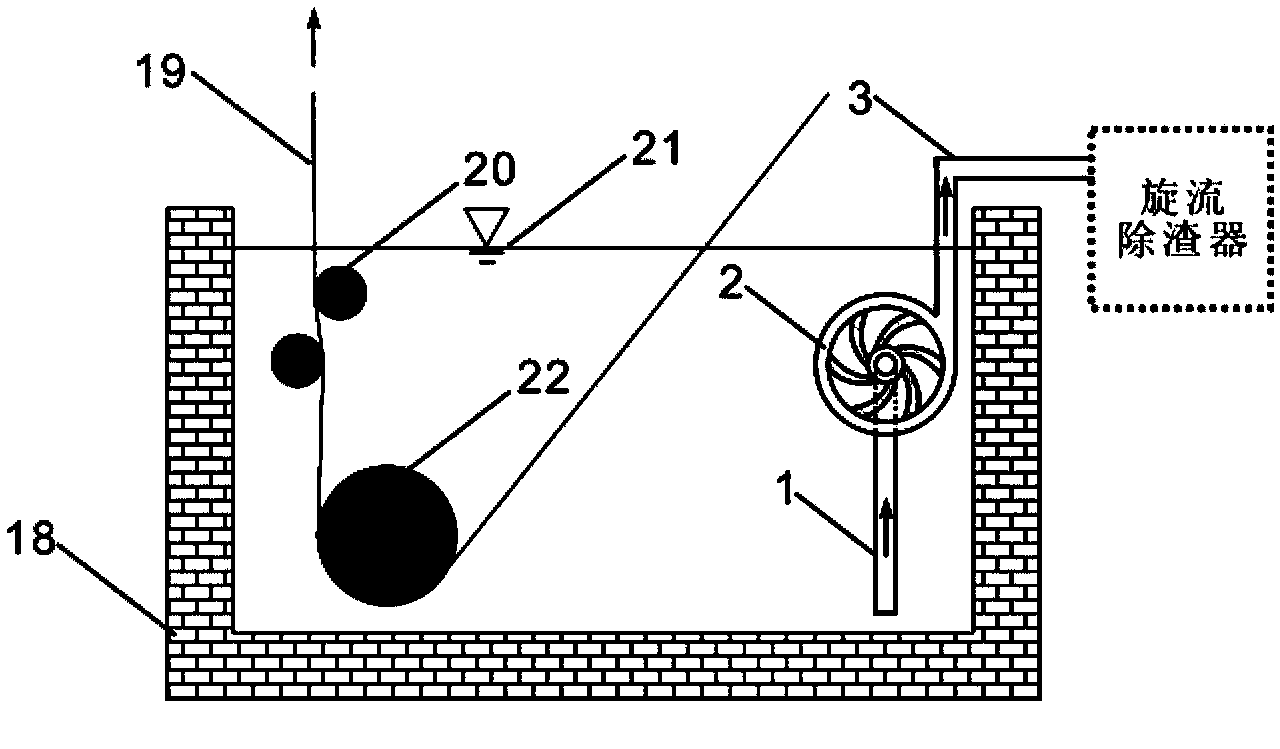

[0022] combine figure 1 with figure 2 As shown, the continuous hot-dip galvanized centrifugal cyclone slag removal device of the present invention includes a high-speed aluminum-zinc pump 2, a centrifugal cyclone inlet 4, a centrifugal cyclone top cover 6, a centrifugal cyclone main body 8, a centrifugal cyclone The device base 10, the aluminum-zinc slag collector 15, the aluminum-zinc liquid introduction pipe 1, the diversion pipe 3, the overflow pipe 5, the slag discharge pipe 14, etc., the reinforcing rib 9 is installed on the main body 8 of the centrifugal cyclone, and the centrifugal cyclone A centrifugal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com