Aluminum electrolytic bath anode current distribution-based online measuring device and measuring method thereof

An anode current and aluminum electrolytic cell technology, applied in the field of online measurement devices, can solve the problems that cannot truly reflect the distribution of the anode current of the electrolytic cell, and achieve the effects of short detection time, high measurement accuracy and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

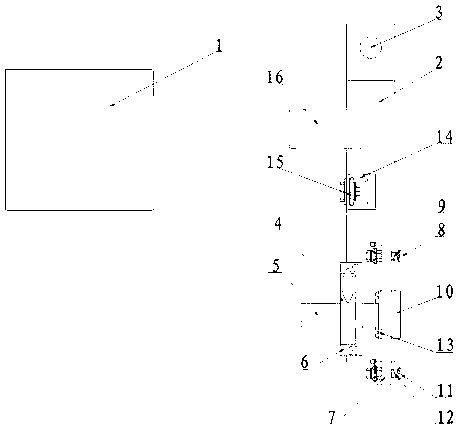

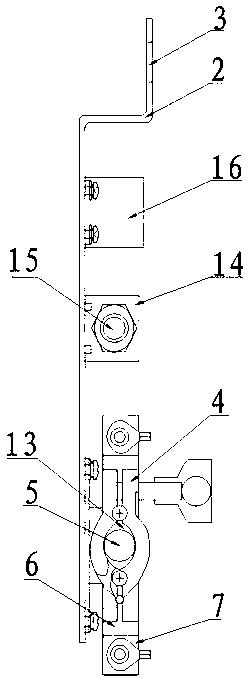

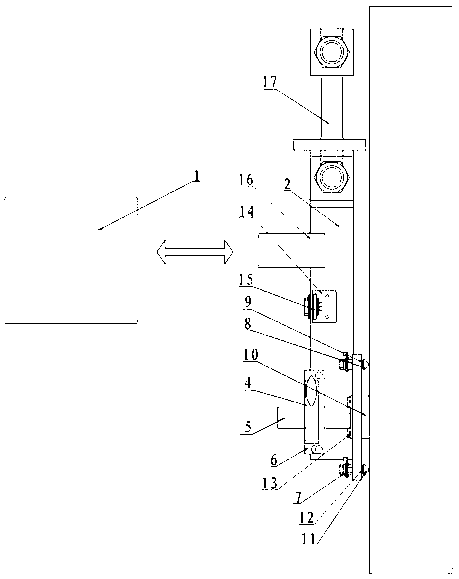

[0041] Such as Figure 1~4As shown, the present invention is used to measure the real-time distribution of the anode current of an aluminum electrolytic cell, which includes a control system 1, a substrate 2, a signal transmission device, a propulsion mechanism, a signal acquisition device, and an anode current collector 16, wherein the control system 1 uses For processing the collected signals to obtain the real-time current distribution of the anode guide rod, the control system 1 is the same as the control system in the background art, and it is a prior art, so it will not be described in detail. The control system 1 is connected with the anode current collector 16 through wireless communication, therefore, the anode current collector 16 can transmit signals to the control system 1 in the form of wireless transmission. The anode current collector 16 is installed on the base plate 2, and the base plate 2 is provided with a mounting hole 3, which matches the nut on the bus ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com