Improved heat-setting machine

A heat-setting machine and shell technology, which is used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of different bonding effects of cotton layers, affecting product quality, and increasing the amount of viscose fiber. To achieve the effect of rapid, balanced and stable heating, good heat setting effect, and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

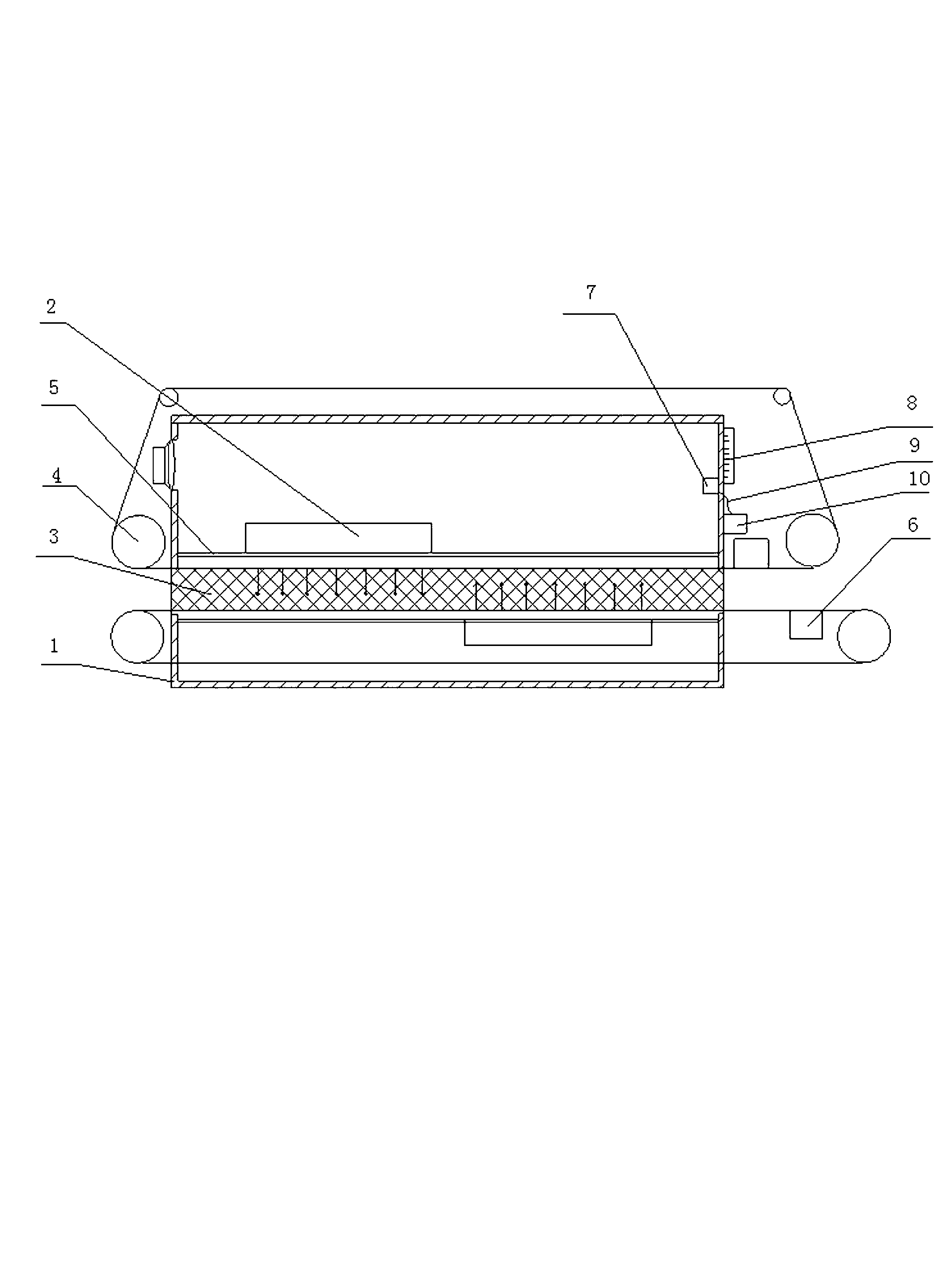

[0012] Such as figure 1 As shown, an improved heat setting machine of the present invention includes a thermal insulation shell 1, a blowing and suction slot 2 arranged in the thermal insulation shell 1, and a conveyor belt 3 for clamping the cotton layer, and the conveyor belt 3 is a Teflon mesh belt , the conveyor belt 3 is driven by the transmission roller 4, the blowing and suction air groove 2 is set on the guide roller 5 in the shell, and can move left and right with the guide roller 5, and the cooling air that closely fits the conveyor belt is installed at the exit of the heat preservation shell 1 Groove 6, thermal insulation shell 1 is provided with infrared drying device 7, and the outer side of thermal insulation shell 1 is provided with thermometer 8, and infrared drying device 7 is connected with the temperature adjustment switch 10 that is located at the outside of thermal insulation shell 1 through wire 9. The upper and lower sides of the conveyor belt 3 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com