Bridge maintenance overhead working equipment lifting device

A technology of operating equipment and lifting devices, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of unrealizable, short construction period, high cost, etc., and achieve the effect of simple and reasonable structure, safe operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0024] For the convenience of understanding, the direction along the bridge is defined as the longitudinal direction, and the direction across the bridge is defined as the transverse direction.

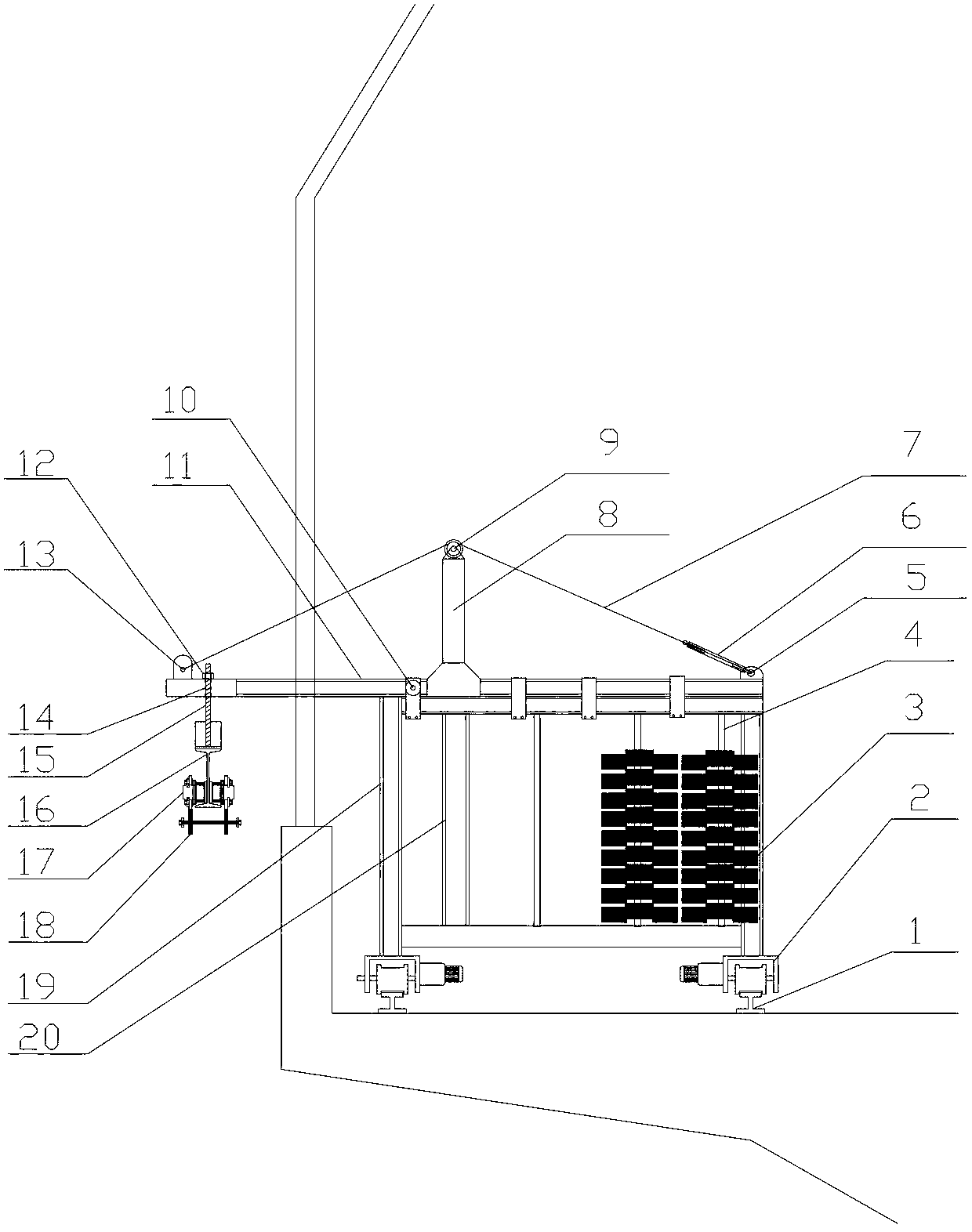

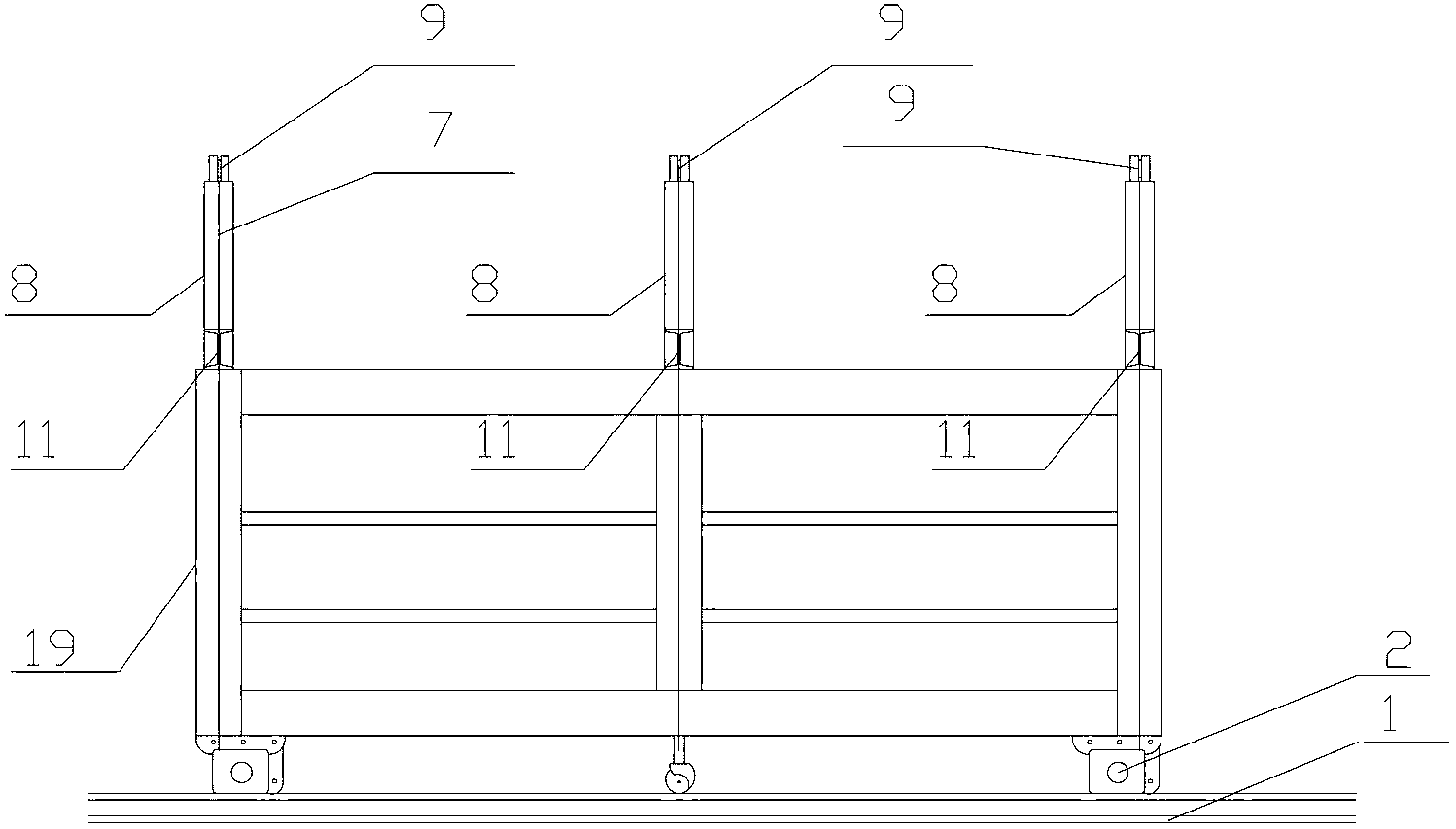

[0025] Such as figure 1 Shown is the self-propelled suspension mechanism passing lamp post device of the bridge inspection and maintenance equipment of the present invention. The vehicle frame on the vehicle frame walking dolly 2. Wherein, the vehicle frame includes a front bracket 20 close to the inner side of the bridge guardrail and a counterweight bracket 4 away from the inner side of the bridge guardrail, and a corresponding number of counterweights 3 are installed on the counterweight bracket 4 according to the weight of the actually installed height-climbing operation equipment to keep the system stable . Three suspension steel arms 11 are hinged equidistantl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com