Hydraulic vibratory hammer device and vibration excitation method thereof

A hydraulic vibration hammer and vibration exciter technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of gear planetary gears and crown gears that are easily damaged, large manpower and financial resources, and low life of vibration hammers. , achieve the effect of cost reduction, good applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in detail:

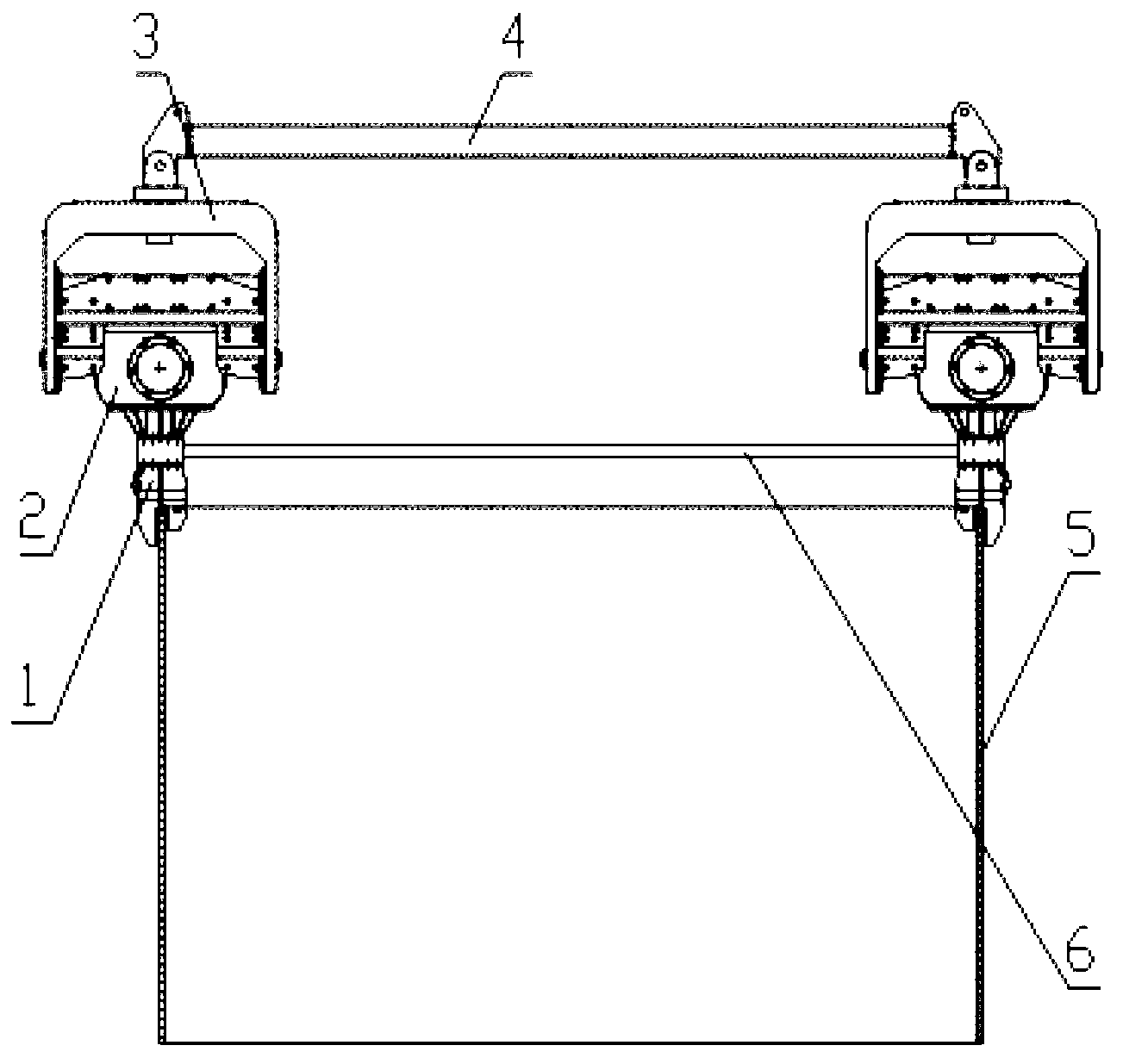

[0024] figure 1 The ZZYY160 type electric vibratory hammer device implemented for the present invention includes: a damping beam 3, an eccentric rotary vibrator 2 and a fixture 1, the damping beam 3 is connected with the eccentric rotary vibrator 2 through a pin shaft, and the eccentric rotary vibrator The device 2 is connected to the fixture (1) through a flange, and the eccentric rotary vibrator 2 has only one eccentric rotary system, that is, a motor or an electric motor drives an eccentric mass to rotate to generate vibration.

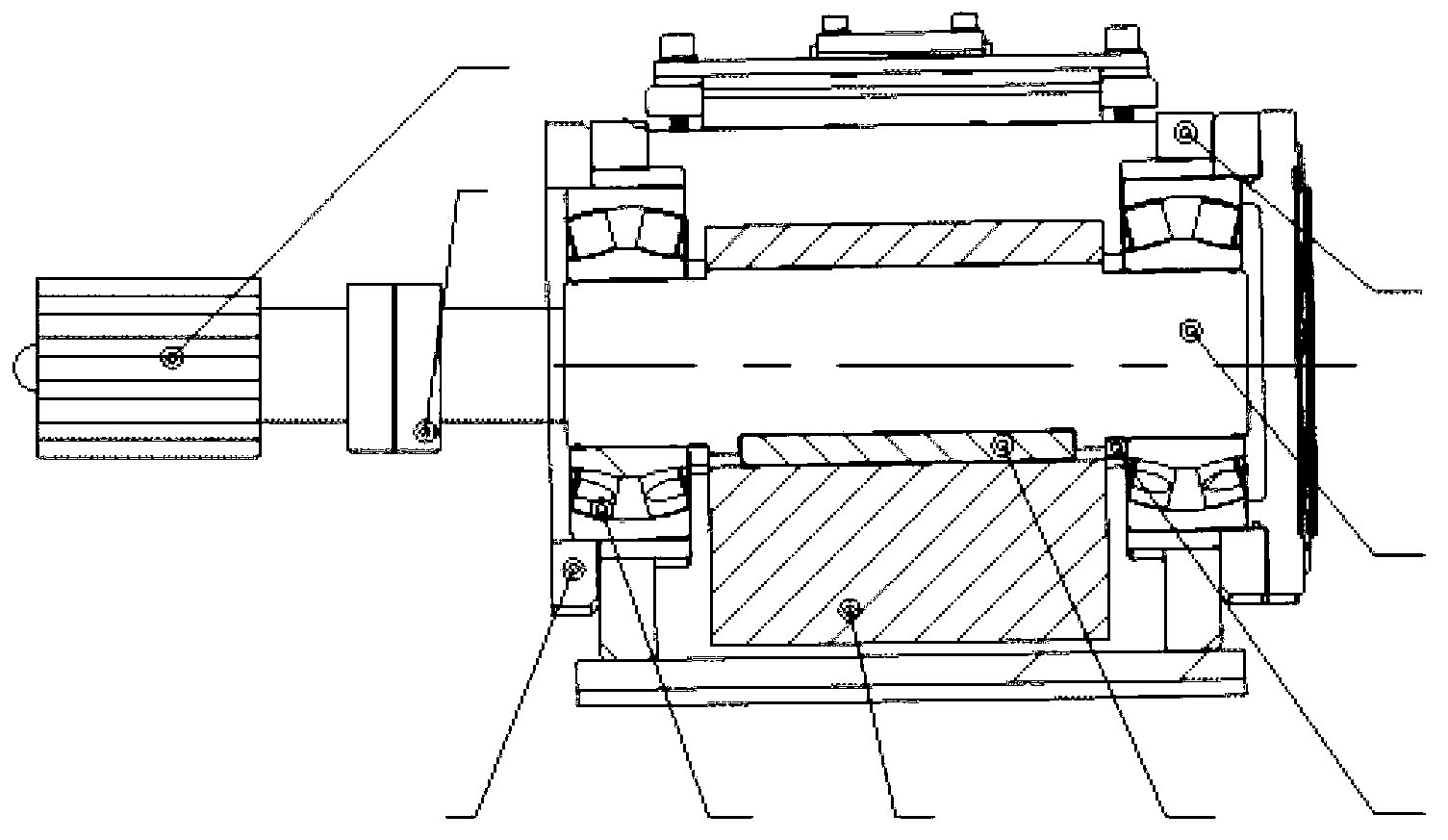

[0025] Such as figure 2 , the structure of the eccentric rotary vibrator 2 is as follows: the bearing seat 8 is fixed on the box body 14, the bearing 9 is installed on the bearing seat 8, the shaft 13 is interference fit with the bearing seat 8, and the eccentric block 10 is installed on the shaft through the flat key 11. 13, the sleeve 12 is used to posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com