Quick construction device for inner wall of arch crown oil tank

A vaulted oil tank and rapid technology are applied in the field of rapid construction devices for the inner wall of a vaulted oil tank, which can solve the problems of waste of scaffolding labor costs, large volume of steel oil tanks, low labor efficiency, etc., so as to improve construction efficiency and reduce quantity , the effect of improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

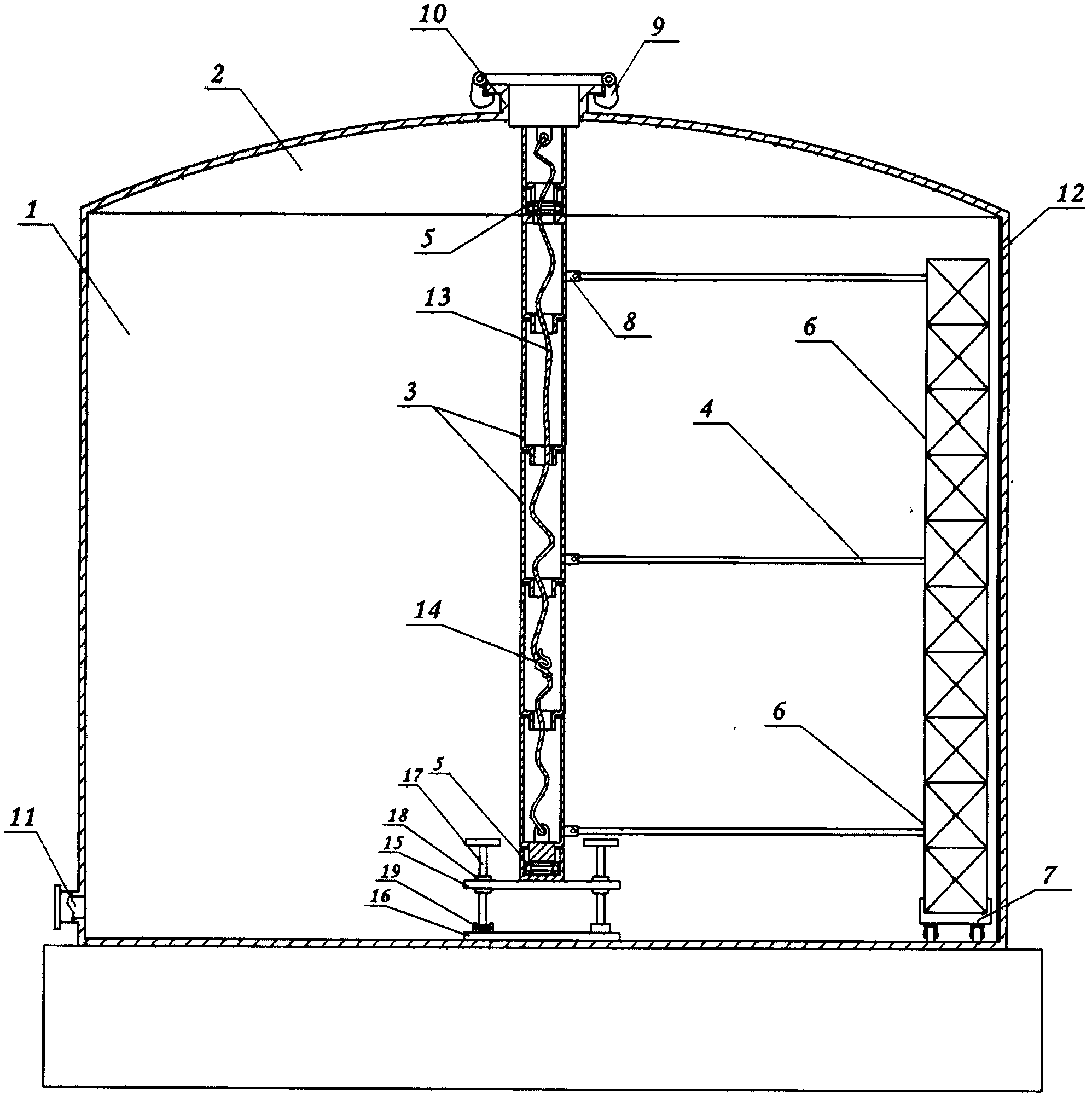

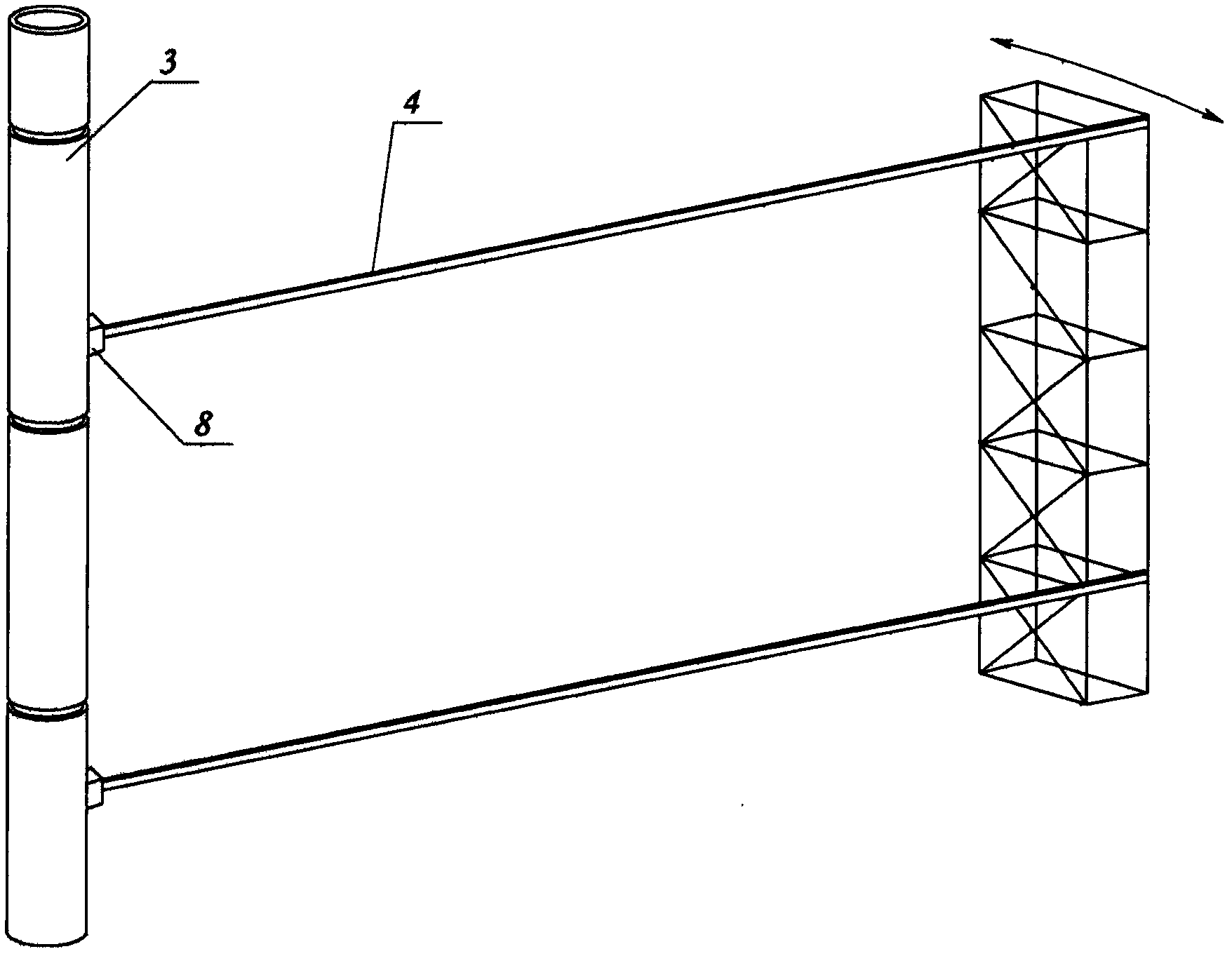

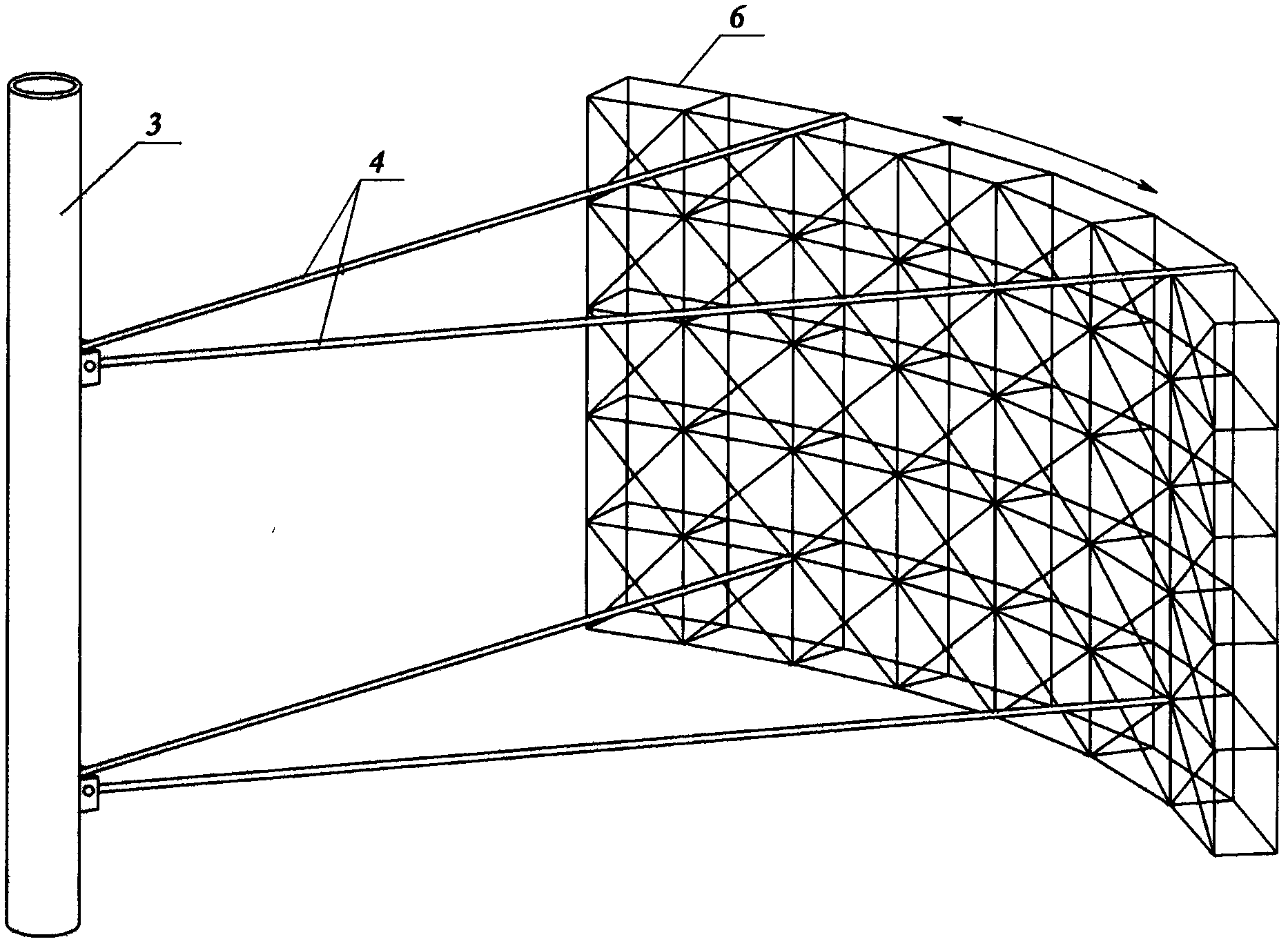

[0020] Embodiment 1: see figure 1 , The oil tank body 1 is fixed on the base 9. The upper part of the oil tank 1 includes a dome 2, a manhole 10 is arranged in the center of the dome 2, and the outer edge of the manhole 10 is set as a flange. There is a combined column 3 through the suit in the manhole. In the oil tank 1, a support frame 6 corresponding to the height of the inner wall of the oil tank is also provided. The lowermost layer of the support frame 6 is provided with a universal wheel and a brake mechanism 7. The support frame 6 is as follows: figure 2 Vertical single-row structure, the four corners of the lower end are respectively equipped with universal wheels and brake mechanisms; or the support frame 6 is as image 3 A combination of multiple single-row structures, the combination bracket is consistent with the radian of the inner wall of the oil tank, and a plurality of universal wheels and brake mechanisms are sequentially installed at the lower end of the ...

Embodiment 2

[0023] Example 2: see Figure 4 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the connecting rod adopts a sleeve telescopic connecting rod 4, and the butt joint of the sleeve is fixed by tightening screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com