Method for top lift installation of inner tank and outer tank of double-wall storage tank

An installation method and a tank roof technology are applied in the construction field of manufacturing and installing large and medium-sized double-wall storage tanks. The effect of improving the construction period and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

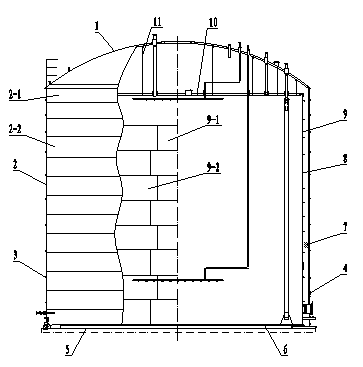

[0037] see figure 1 , the double-wall storage tank is composed of an inner tank and an outer tank, and an insulating layer 7 is arranged between the inner and outer tanks. The inner tank and the outer tank of the double-wall storage tank are made of different metal materials. They are assembled and welded by a certain number of wall strip plates into the inner tank wall cylinder 9 and the outer tank wall cylinder 2, and then the inner tank wall cylinder 9, The outer tank wall cylinder 2 is welded with the inner tank bottom plate 6 and the outer tank bottom plate 5 respectively, and the inner tank roof 10 with a flat ceiling structure is arranged on the top of the inner tank wall cylinder body 9 , and an arched structure is arranged on the top of the outer tank wall cylinder body 2 The top of the outer tank 1. The inner tank roof 10 of the double-walled storage tank is suspended, and is suspended on the outer tank roof 1 by a suspender 11;

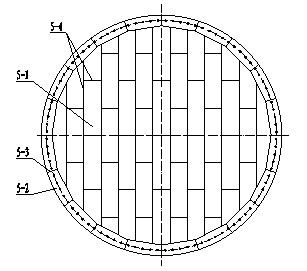

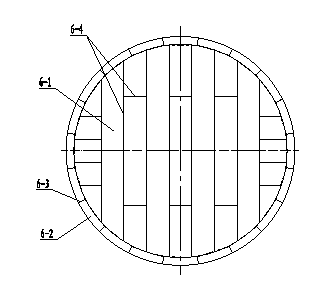

[0038] see Figure 2 to Figure 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com