Door/window rubber sealing strip for anti-explosion safety inspection

A technology of rubber and seals, applied in adhesives, sealing devices, film/sheet adhesives, etc., can solve the problems of increased monitoring costs, etc., and achieve the effect of simple use and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

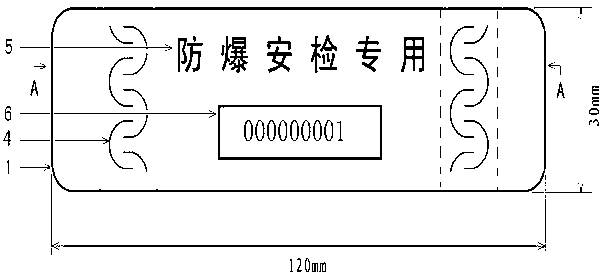

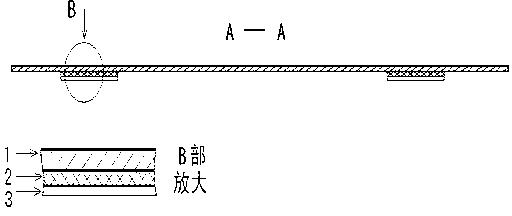

[0033] Embodiment 1: see figure 1 , figure 2 , the present invention is made up of door and window rubber seal rubber surface layer (1), rubber bonding layer (2) and antisticking layer (3) for explosion-proof security inspection, and its profile is that one side is long and is 120mm, and the other side is long and is the rectangle of 30mm. The rubber surface layer (1) is made of vulcanized rubber sheet with ethylene propylene diene monomer (EPDM) as the main material, and its thickness is 1 to 2 mm. Its production process is:

[0034] Use the usual rubber mixing method to mix each raw material into the required rubber compound, then press the rubber compound into a rubber sheet with a thickness that meets the requirements with a calender, and then vulcanize it at 143°C for 10 years with a flat vulcanizer. The vulcanized rubber sheet is produced in minutes, and finally cut with a cutter or punched into a rubber surface layer (1) with a mold. The rubber composition component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com