Tunnel or roadway excavating method under weak and broken complicated geological conditions

A technology for complex geological conditions and tunnels, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as advance support, and achieve the effects of fewer procedures and equipment, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

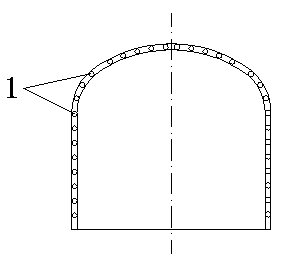

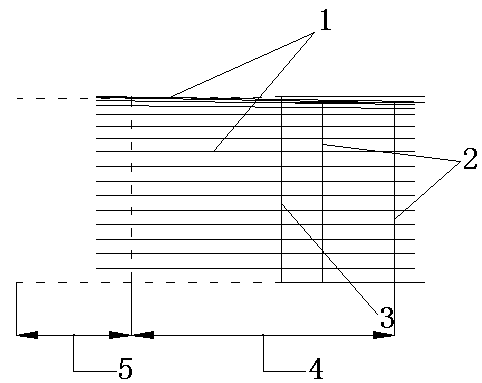

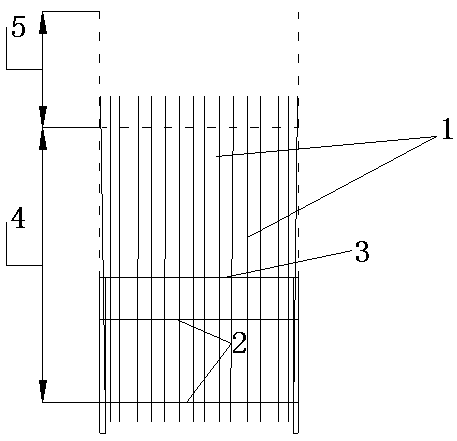

[0023] (1) Preparatory work: including clearing the pumice, leveling the working face 3, checking the rock mass of the working face 3, reasonably arranging the distance between the self-drilling steel drill 1, determining the reasonable length of the steel drill 1, estimating the amount of steel drill 1, and selecting the appropriate steel drill Arch frame 2, before operation, ensure that materials and equipment are in place, and prefabricated concrete pads.

[0024] (2) Self-drilling steel drill 1 operation: Arrange the construction sequence of self-drilling steel drill 1, work continuously clockwise along the working surface, and control the camber angle of steel drill 1 to 4 o The length of the steel drill 1 passes through the muddy rock layer 4 and enters the stable rock formation 5. The steel drill 1 will be extended when drilling, and the length of a single steel drill 1 is 4m; Construction, self-drilling steel brazing 1 is no longer taken out after construction, and the...

Embodiment 2

[0029] (1) Preparatory work: including cleaning pumice, leveling the working face 3, checking the rock mass of the working face 3, reasonably arranging the distance between the self-drilling drill rod 1, determining the reasonable length of the drill rod 1, estimating the amount of the drill rod 1, and selecting the appropriate steel Arch frame 2, before operation, ensure that materials and equipment are in place.

[0030] (2) Self-drilling drill rod 1 operation: Arrange the construction sequence of self-drilling drill rod 1, work continuously counterclockwise along the working surface, and control the camber angle of drill rod 1 to 2 o , the length of the drill rod 1 passes through the weak and broken zone 4, and enters the stable rock formation 5. When the drill rod 1 is drilled, it will be extended, and the length of a single drill rod 1 is 4m; Construction, self-drilling drill rod 1 is no longer taken out after construction, and every drill rod 1 exposed length gets 350mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com