Efficient household ventilating fan with motor forced ventilation and integral heat dissipation structure

A technology of overall heat dissipation and forced ventilation, applied to electrical components, cooling/ventilation devices, components of pumping devices for elastic fluids, etc., to reduce energy consumption, facilitate repair and maintenance, and increase air volume and air pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

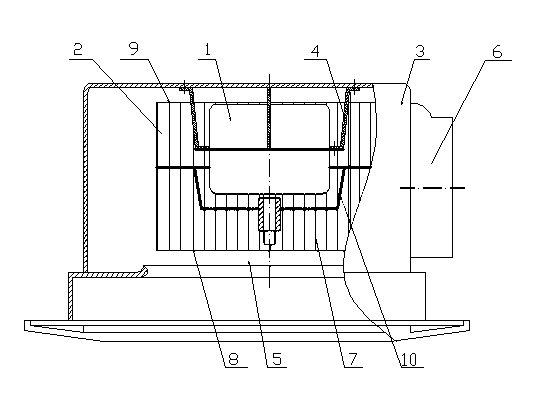

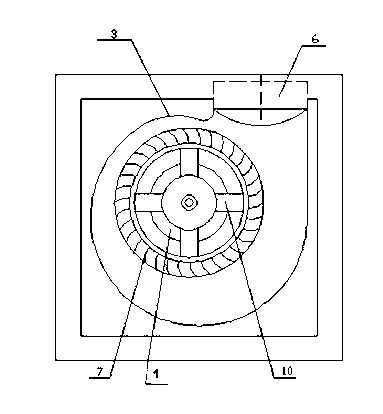

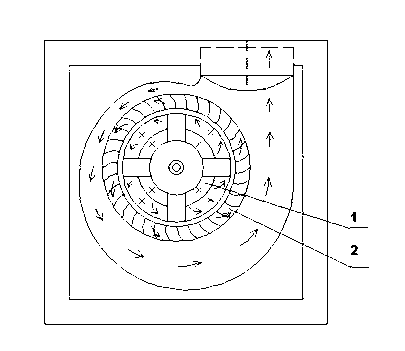

[0017] Such as Figure 1 to Figure 3 As shown, the present invention has a household ventilating fan with a motor integral forced ventilation heat dissipation structure including a motor 1, a wind wheel 2, a volute 3 and a base 10, and the rotating shaft of the wind wheel 2 and the motor 1 is fixed together through the base 10, and the motor 1 It is fixedly connected with the volute 3 and completely placed inside the volute 3 .

[0018] The base 10 is a wind wheel base, which can be cross-shaped, rice-shaped, "*"-shaped, etc., and can also be directly opened on the base 10, so that the air sucked from the air inlet of the household ventilation fan can smoothly enter the motor. 1 and the area between the blades, forming the airflow over the surface of the motor.

[0019] In the present invention, if the upper surface of the upper blade fixed ring 9 of the wind wheel 2 is arranged at a position not lower than the upper surface of the motor 1, or the lower surface of the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com