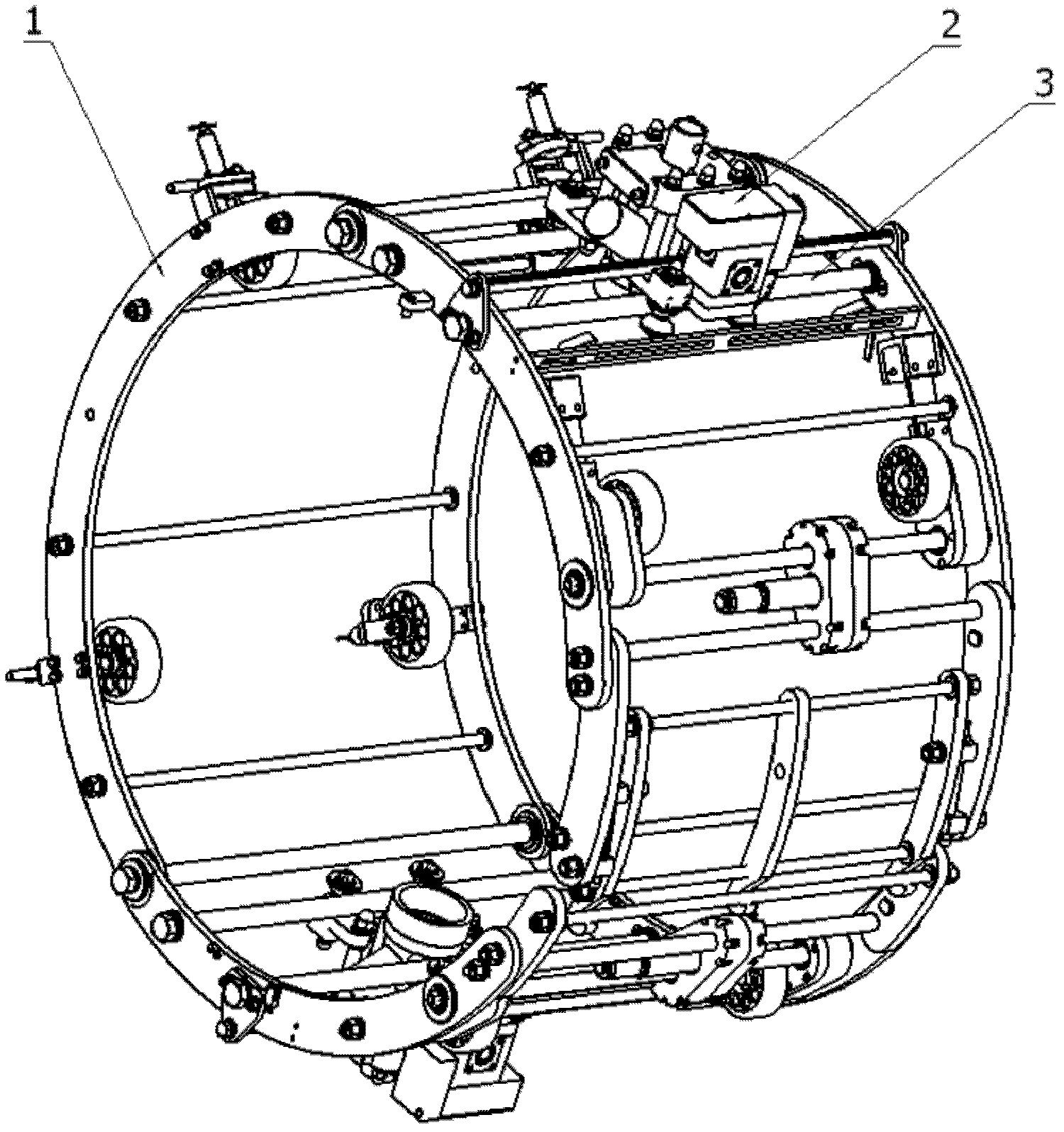

Clamping positioning mechanism for V-shaped wheel of airtight automatic de-rusting machine for pipeline repaired port

A technology of clamping and positioning and derusting machine, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of reducing the service life of pipes, environmental pollution, waste of sand materials, etc., and achieves prolonging service life, simple mechanism structure, The effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

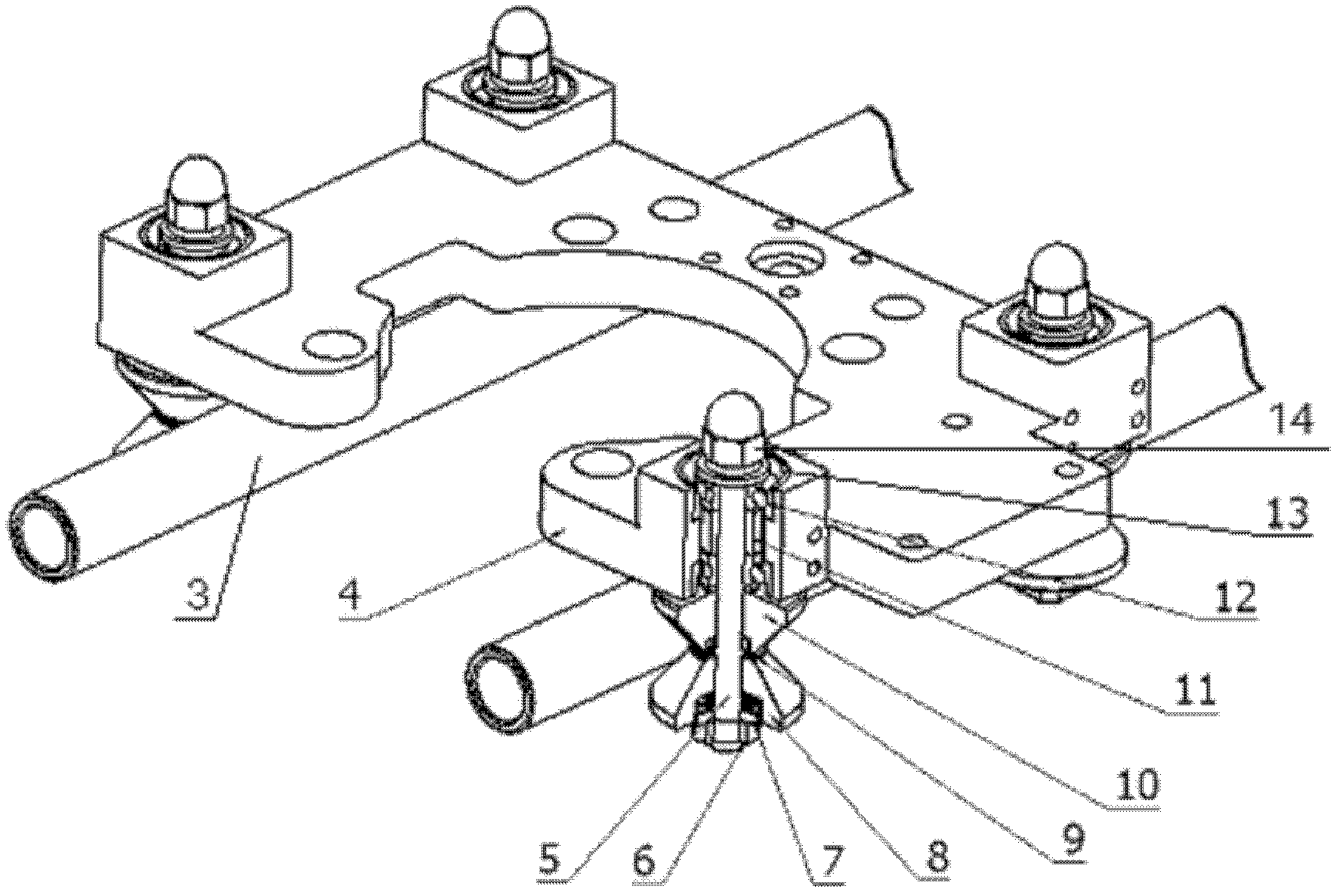

[0012] In the V-shaped wheel clamping and positioning mechanism, the upper conical wheel 10 and the lower conical wheel 8 are connected in series by the lower part of the clamping wheel shaft 5 to form a V-shaped wheel group, and the upper conical wheel 10 and the lower conical wheel 8 are provided. There is a butterfly spring 9; the upper part of the clamping wheel shaft 5 is connected to the bearing seat hole 13 on the bottom plate 4, and the bearing seat hole 13 is provided with a bearing retaining ring 11 and a bearing 12, and the two ends of the clamping wheel shaft 5 are provided with cap nuts 14, gaskets 7 and locking nut 6 lock; The V-shaped draw-in slot of the V-shaped wheel group fixed on the bottom plate 4 contacts and clamps with the guide light rod 3, and the guide light rod 3 is made of stainless steel tube, and the tapered wheel is made of polyoxymethylene.

[0013] The specific operation is as follows:

[0014] The bearing 12 and the bearing retaining ring 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com