Non-detaching cleaning device for enclosed cover of rotary drum drier

A drum drying and cleaning device technology, which is applied in the direction of drying solid materials, cleaning methods using liquids, drying, etc., can solve problems such as hindering dried products, and achieve the effects of simple structure, reliable operation, and clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

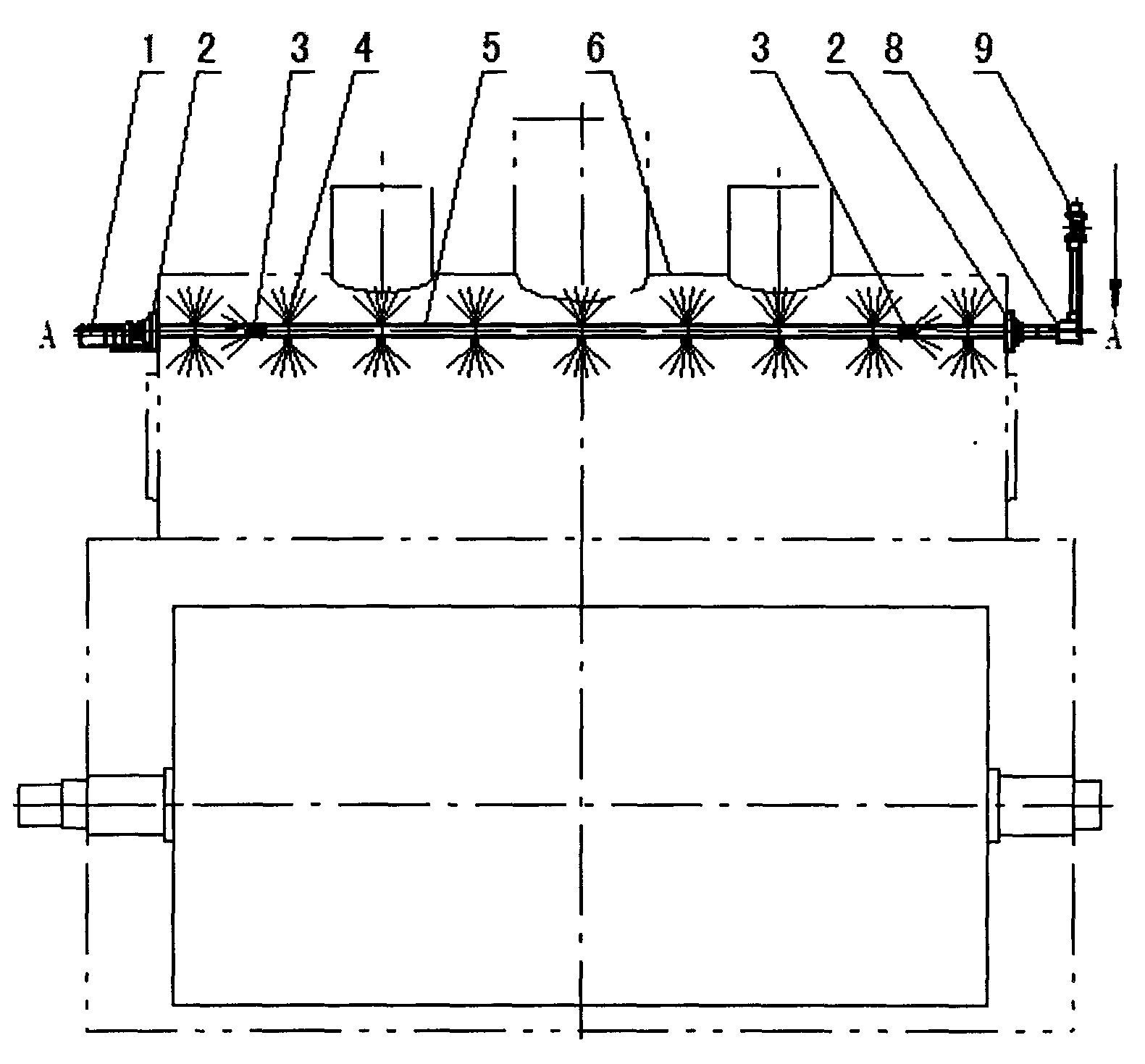

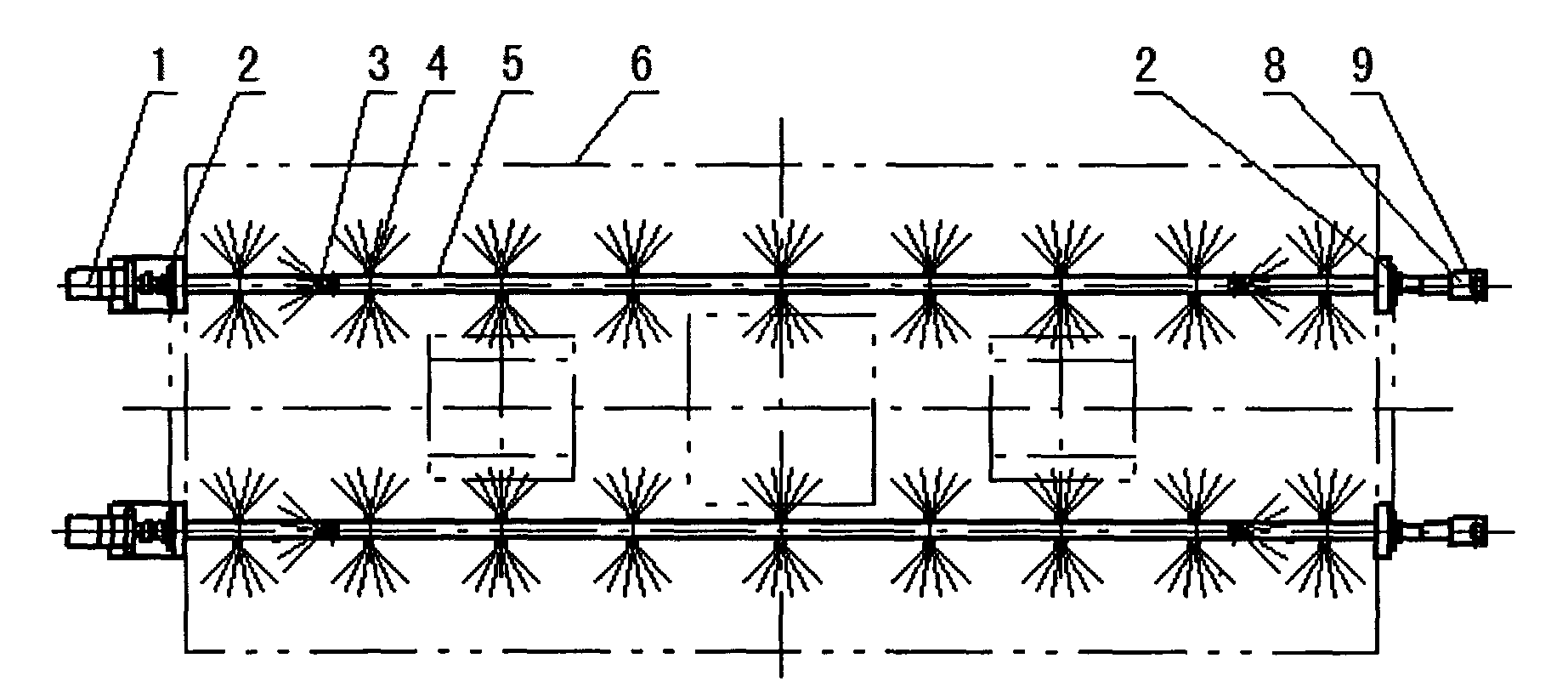

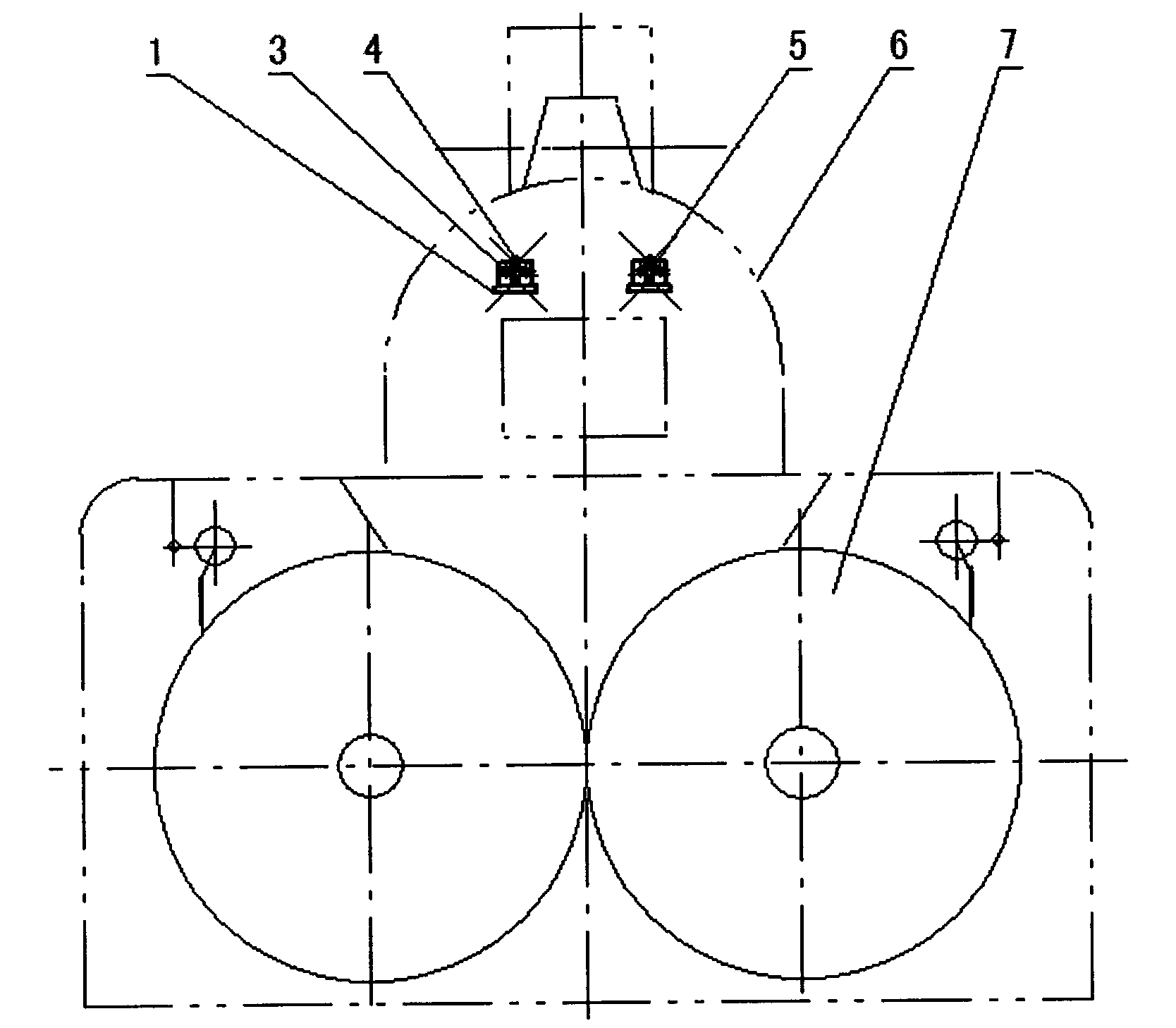

[0022] Example 1 figure 1 , figure 2 and image 3 Shown is the embodiment of the present invention installed on the hood of a double drum dryer:

[0023] The non-dismantling machine cleaning device of the two sets of drum dryer airtight covers takes the center line of the side of the airtight cover (6) as the symmetrical center, and is horizontally arranged on the upper part of the airtight cover (6). Two sets of bearing housings (2) of the machine cleaning device are respectively fixedly installed on the outsides of the wall panels at both ends of the airtight cover (6). 7) The axis lines are parallel; one end of the tubular shaft (5) is a solid shaft, and this end is connected with the fixed motor deceleration transmission device (1) installed on the outer upper part of the end wall panel of the airtight cover (6); the tubular shaft (5) The other end outside the bearing seat (2) is connected with the rotary joint (8); the pressurized cleaning solution used for the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com