Anhydrous dyeing process and production line of high-end environment-friendly PU leather base cloth

A technology of waterless dyeing and leather base fabric, applied in the field of textile dyeing and finishing, can solve the problems of unsatisfactory dyeing method of PU leather base fabric, low product quality, low production efficiency, etc., to achieve changes in the production environment, high product quality, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

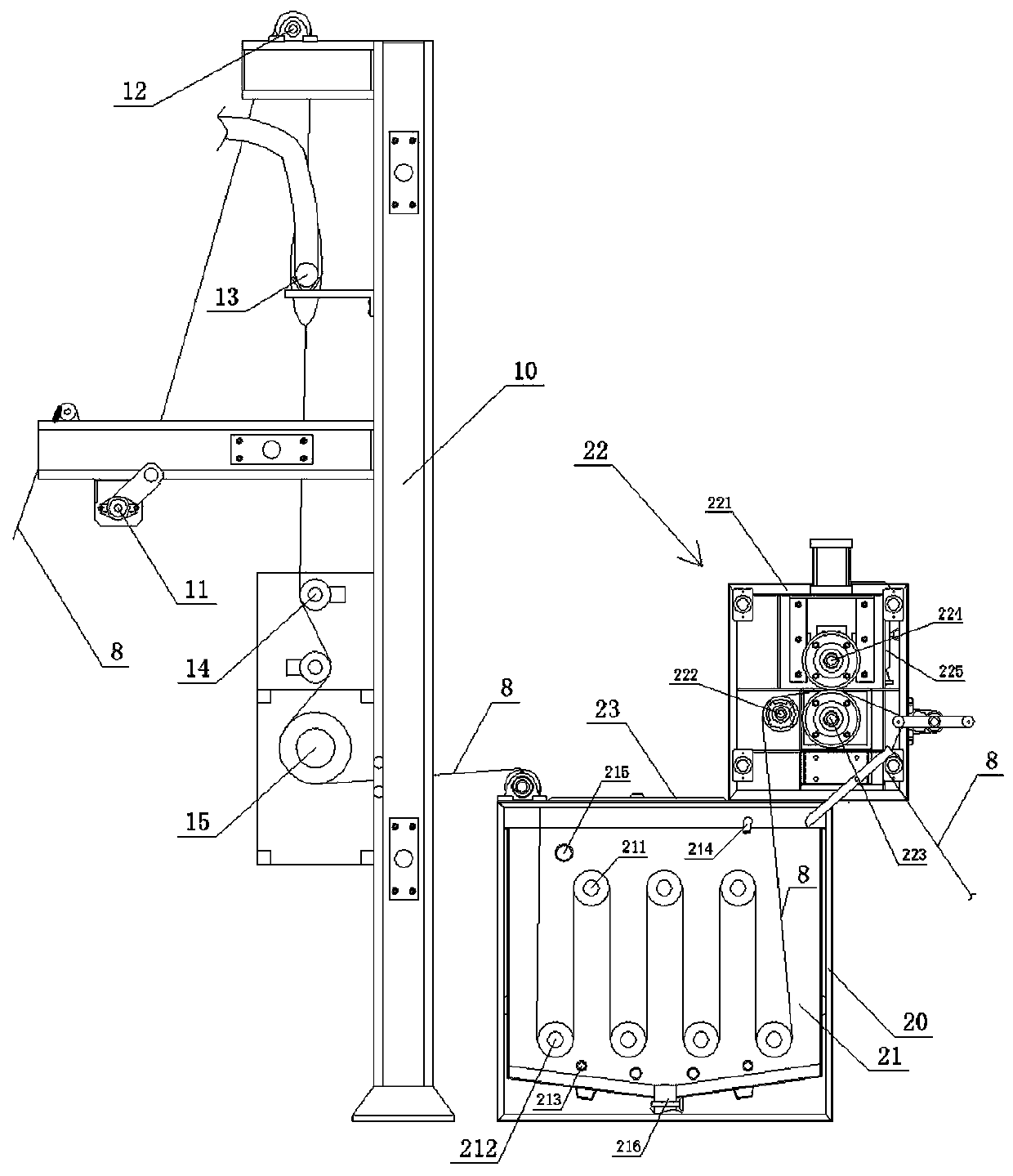

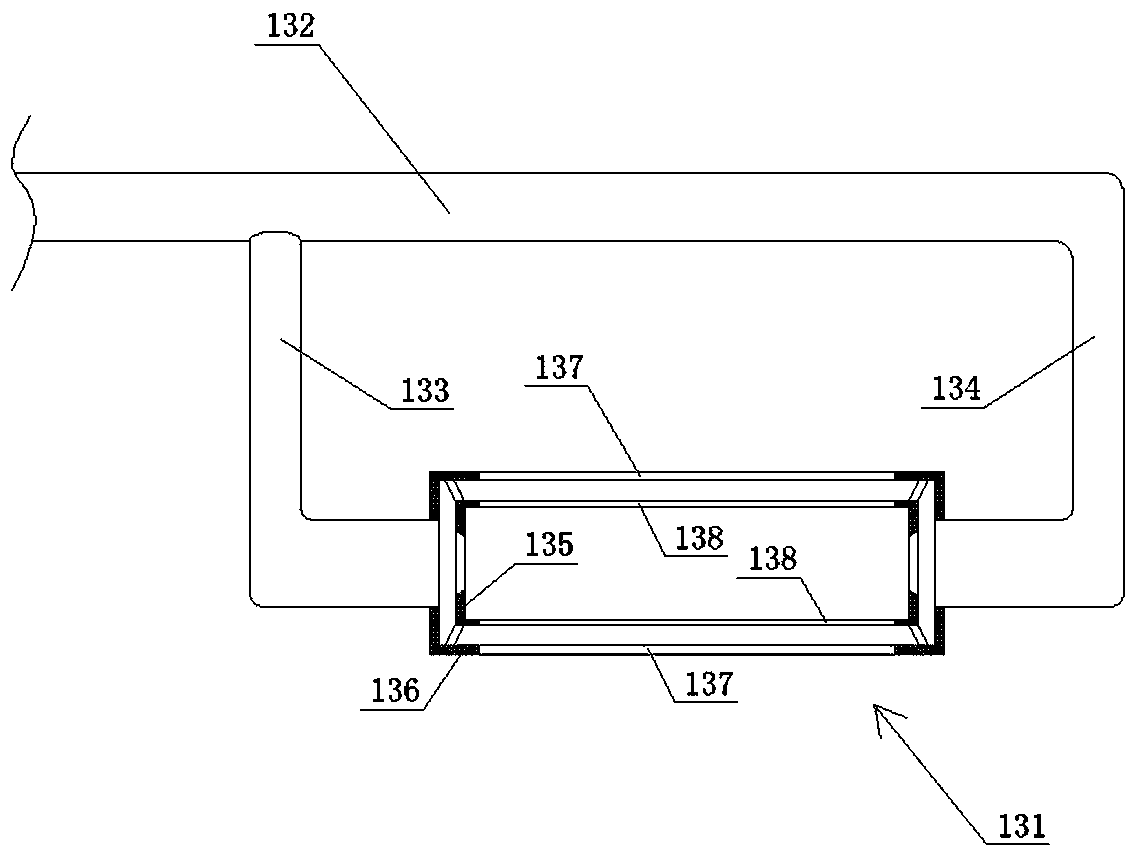

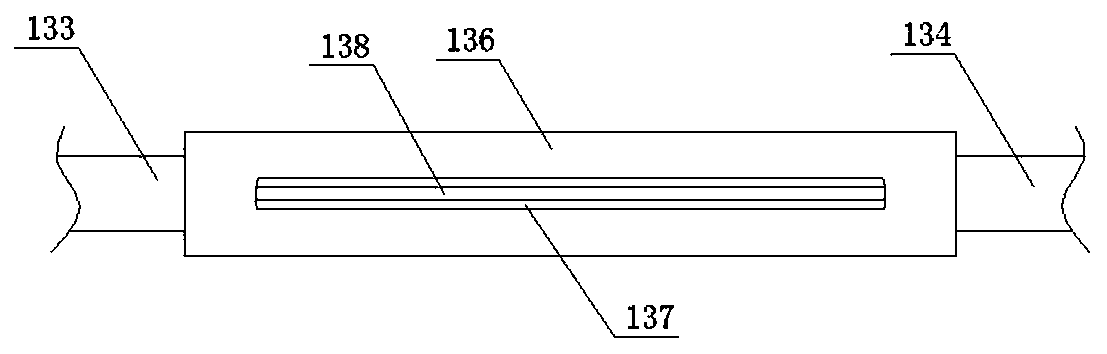

[0038] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0039] High-end environmentally friendly PU leather base fabric anhydrous dyeing process, which includes gray fabrics successively and continuously through the following steps: a) Cloth feeding, the folded and stacked gray fabrics are fed into the cloth in open width; Perform fluff removal.

[0040] b) Desizing: remove the size on the gray cloth after the open width; carry out at least two continuous desizing treatments on the gray cloth after the open width, and after each desizing treatment, the gray cloth needs to be rolled by a roller Roll dry.

[0041] c) Water washing: the desized gray cloth is subjected to continuous water washing treatment; the desized gray cloth is subjected to at least two continuous water washing treatments, and the gray cloth needs to be rolled and dried after each water washing treatment.

[0042] d) drying, drying the washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com