Method and system for controlling air quantity of main draft fan of sintering machine

A main exhaust fan and air volume control technology, applied in the field of sintering technology, can solve problems such as inability to ensure sintering quality, high power consumption and loss, and deviation of the sintering end from a fixed position, etc., so as to save money, save power, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

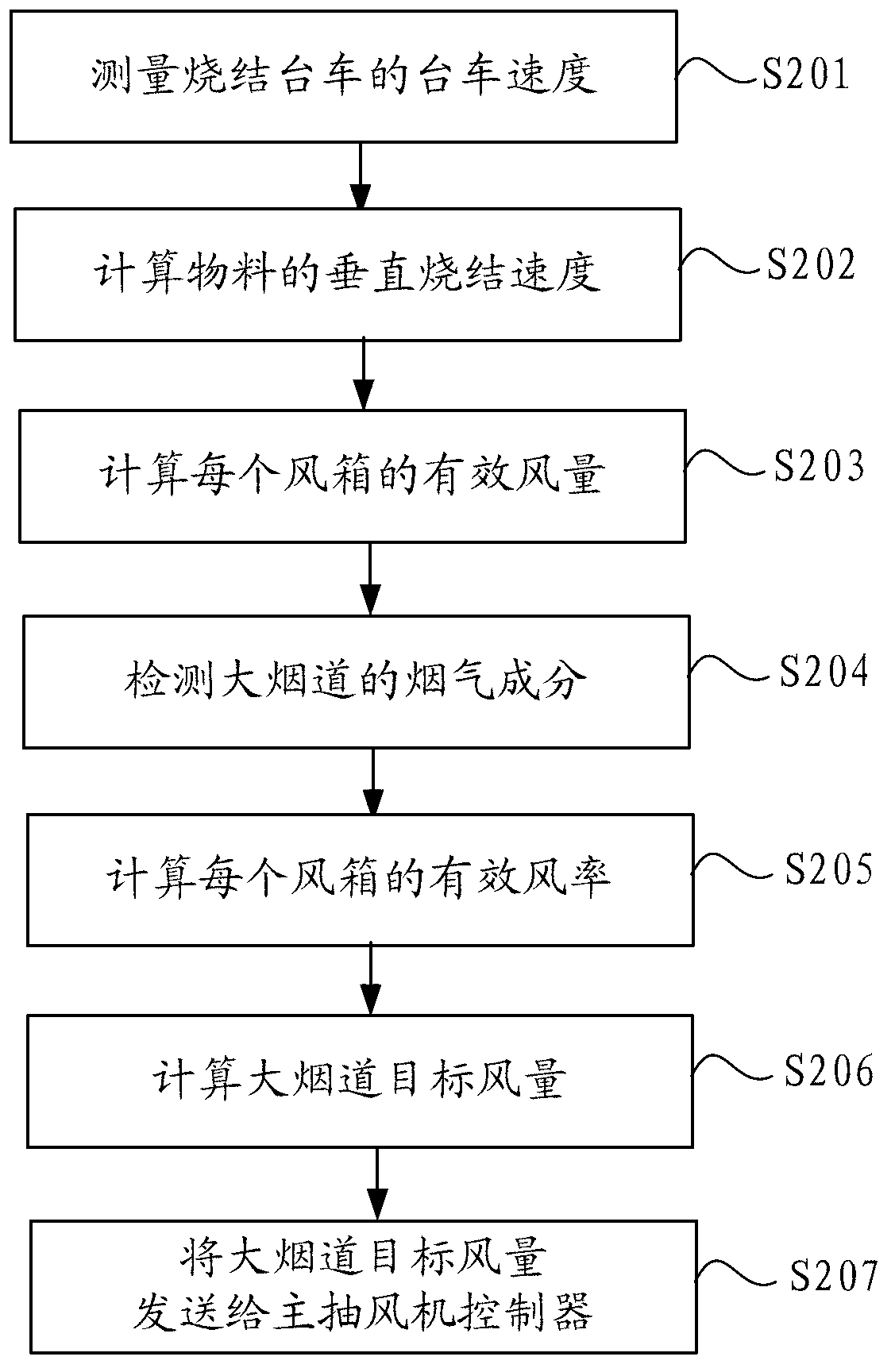

[0040] figure 2 It is a flow chart of the method for controlling the air volume of the main exhaust fan provided in Embodiment 1 of the present application.

[0041] Such as figure 2 As shown, the method includes:

[0042] S201: Measure the trolley speed of the sintering trolley.

[0043] When measuring the trolley speed of the sintering trolley, the running speed of the trolley set in the trolley control device can be obtained as the trolley speed. However, in actual operation, due to reasons such as wear or mechanical failure, the actual running speed of the trolley may be inconsistent with the set running speed, which will affect the adjustment of the air volume of the main exhaust fan. Therefore, in this embodiment, on the trolley Install a speed sampling instrument to directly detect the actual running speed of the trolley as the speed of the trolley to avoid affecting the adjustment of the main exhaust air volume due to the inconsistency between the actual running s...

Embodiment 2

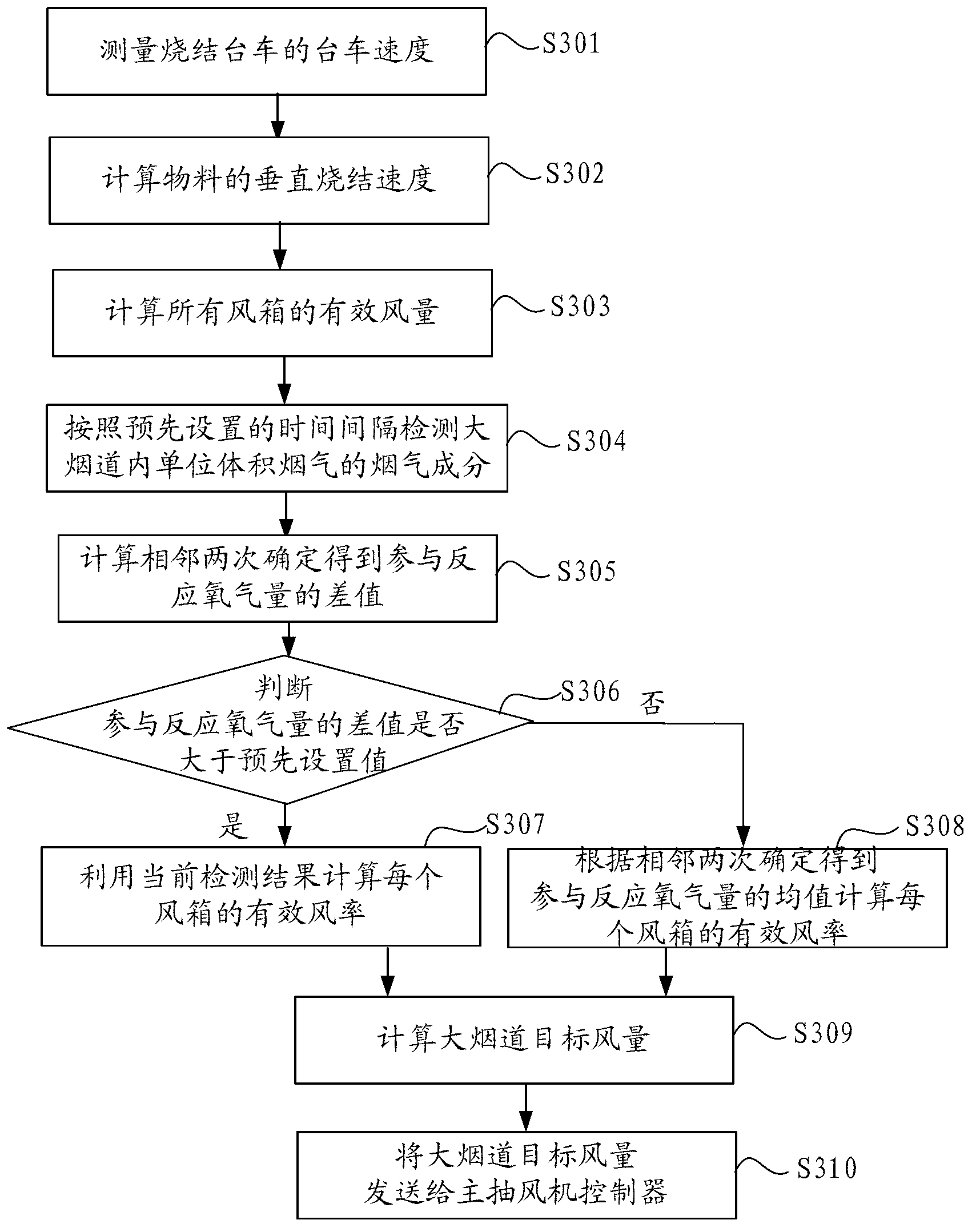

[0092] image 3 It is a flow chart of the method for controlling the air volume of the main exhaust fan provided in the second embodiment.

[0093] according to image 3 As shown, steps S301-S303 are equivalent to steps S201-S203 in Embodiment 1. For detailed descriptions of steps S301-S303, please refer to the description of steps S201-S203 in Embodiment 1 above, which will not be repeated here.

[0094] S304: Detect the smoke components in the unit volume of smoke in the large flue according to the preset time interval.

[0095] Here, in this embodiment, the flue gas component in the unit volume flue gas in the large flue is O in the unit volume flue gas 2 , CO, CO 2 , N 2 , NO, NO 2 content. When detecting the smoke composition of the large flue, the smoke composition of the large flue is detected according to the preset time interval, which can make the detection more adaptable to the change of the system load. For example, when the system load, such as trolley spe...

Embodiment 3

[0114] This example refers to Figure 4 process shown. according to Figure 4 As shown, steps S401-S406 are equivalent to steps S201-S206 in Embodiment 1. For detailed descriptions of steps S401-S406, please refer to the description of steps S201-S206 in Embodiment 1 above, which will not be repeated here.

[0115] S407: Calculate the difference between the target air volume of the large flue obtained from two adjacent calculations.

[0116] S408: Determine whether the difference is greater than a preset value.

[0117] When the judgment result is greater than, execute step S409; otherwise, execute step S410.

[0118] S409: Use the currently calculated target air volume of the large flue as an adjustment parameter.

[0119] S410: Use the average value of the target air volume of the large flue obtained by two adjacent calculations as an adjustment parameter.

[0120] S411: Send the adjustment parameter to the controller of the main exhaust fan.

[0121] When the target a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com