Single-layer cooling type steam-water separator

A steam-water separator and cooling technology, applied in steam/steam condensers, tubular elements, heat exchange equipment, etc., can solve problems such as air pollution, damage to urban atmosphere beautification, and treatment equipment that has not yet had white steam, and achieve elimination Emissions, simple structure, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

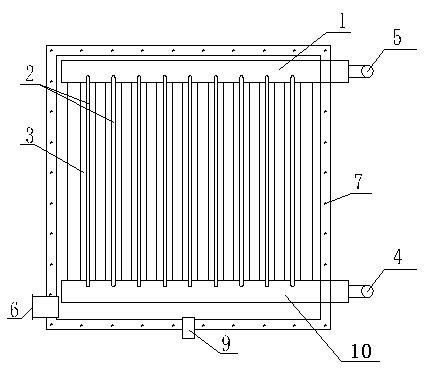

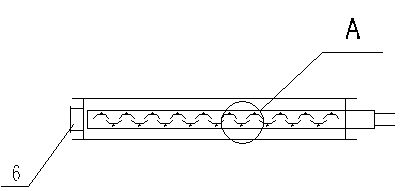

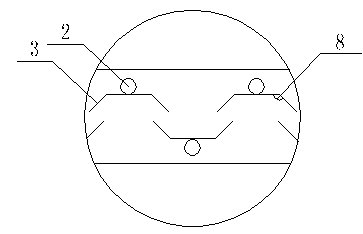

[0019] see figure 1 , figure 2 and image 3 , the present invention includes a steam-water separator body, the steam-water separator body is an airtight cuboid, and the four sides are sealed up, down, left, and right, and the water mist passes through the front and back sides. The upper and lower parts of the steam-water separator body are respectively provided with an upper cold water main pipe 1 and a lower cold water main pipe 10. The upper cold water main pipe 1 and the lower cold water main pipe 10 are set in one group in the steam-water separator body. The upper cold water main pipe 1 and the lower cold water main pipe 10 A cold water branch pipe 2 is arranged between them, and the cold water branch pipe 2 communicates with the upper cold water main pipe 1 and the lower cold water main pipe 10. see figure 2 and image 3 A group of cooling fins 3 is welded to the cold water branch pipe 2, and the group of cooling fins 3 are arranged in a staggered manner in a meshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com