Analyzing method of pollutant absorption capability of deep UV (ultraviolet) fluoride film element

A technology of adsorption capacity and thin-film components, which is applied in the field of deep-ultraviolet optical technology applications, can solve the problems of insufficient internal structure of optical films, performance degradation of thin-film components, and increased absorption of deep-ultraviolet optical films to meet environmental applicability and timeliness Performance evaluation, the effect of high environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example evaluates the adsorption capacity of organic pollutants and water vapor in a standard laboratory environment (temperature 22°C, relative humidity 30%) for a fluoride anti-reflection film prepared under the process parameters of heat boat evaporation.

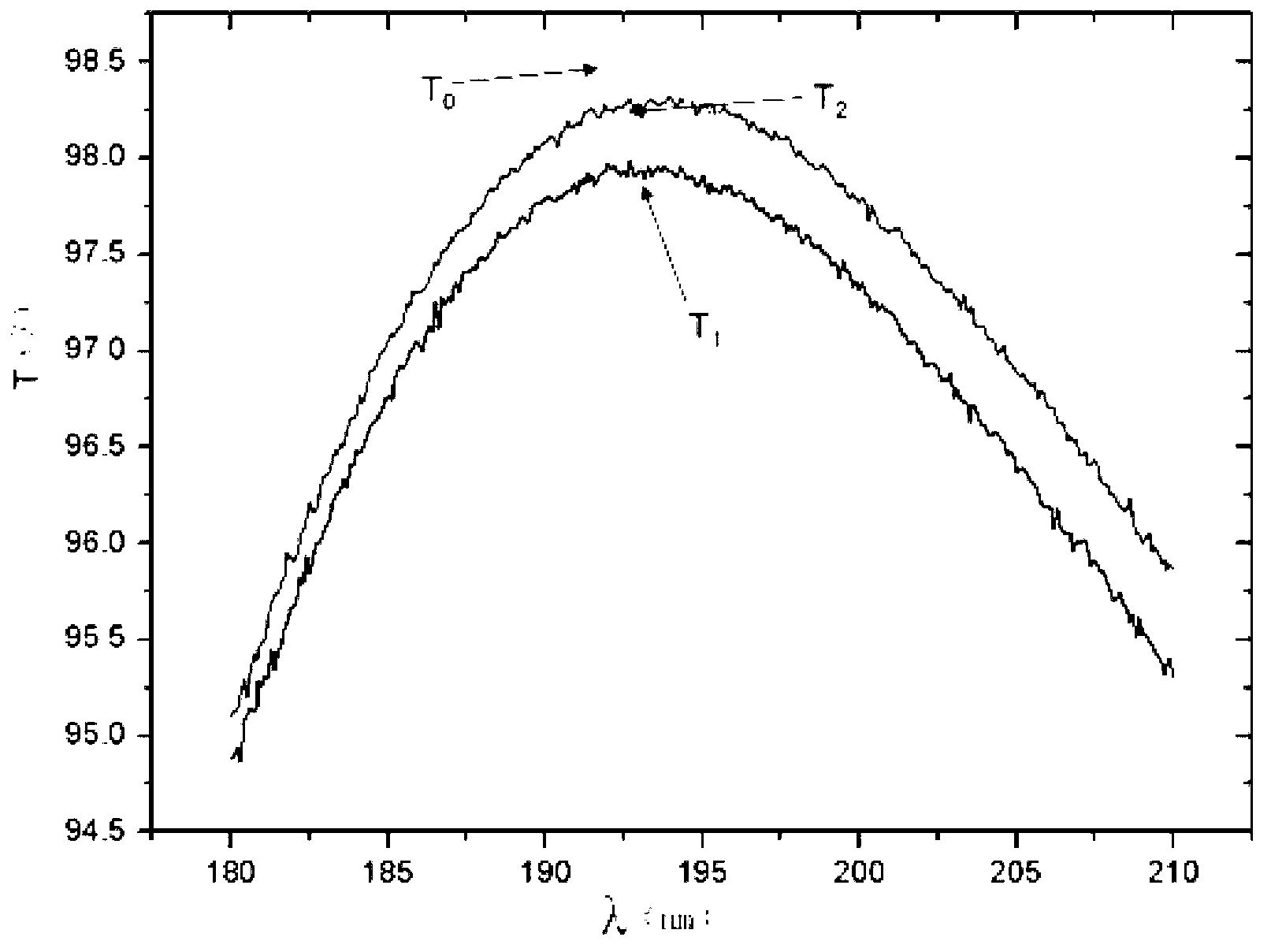

[0028] Such as figure 1 Shown is a spectrum test evaluation chart of the laboratory environment organic pollutants and water vapor adsorption capacity of the deep ultraviolet fluoride anti-reflection film of the present invention.

[0029] Including that after the fluoride anti-reflection film is coated, the spectrophotometer is purged with high-purity N 2 Transmittance tested at 193nm band transmittance T 0 98.4% is used as the initial value of the spectral performance of the anti-reflection film sample.

[0030] After the thin film element was placed in the laboratory environment for 2 weeks, the spectrophotometer was in a vacuum environment (P-6 mbar) to test the transmittance of the sample in the 193nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com