Bridge rectifier automatic testing machine

An automatic testing machine and testing agency technology, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve the misjudgment of testing equipment, the inability to perform initial testing and retesting at the same time, and the bridge stack is incorporated into an inverted "V" shape. The problem of the same position in the groove, etc., can ensure the accuracy and reliability, reduce the manual placement process, and reduce the labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

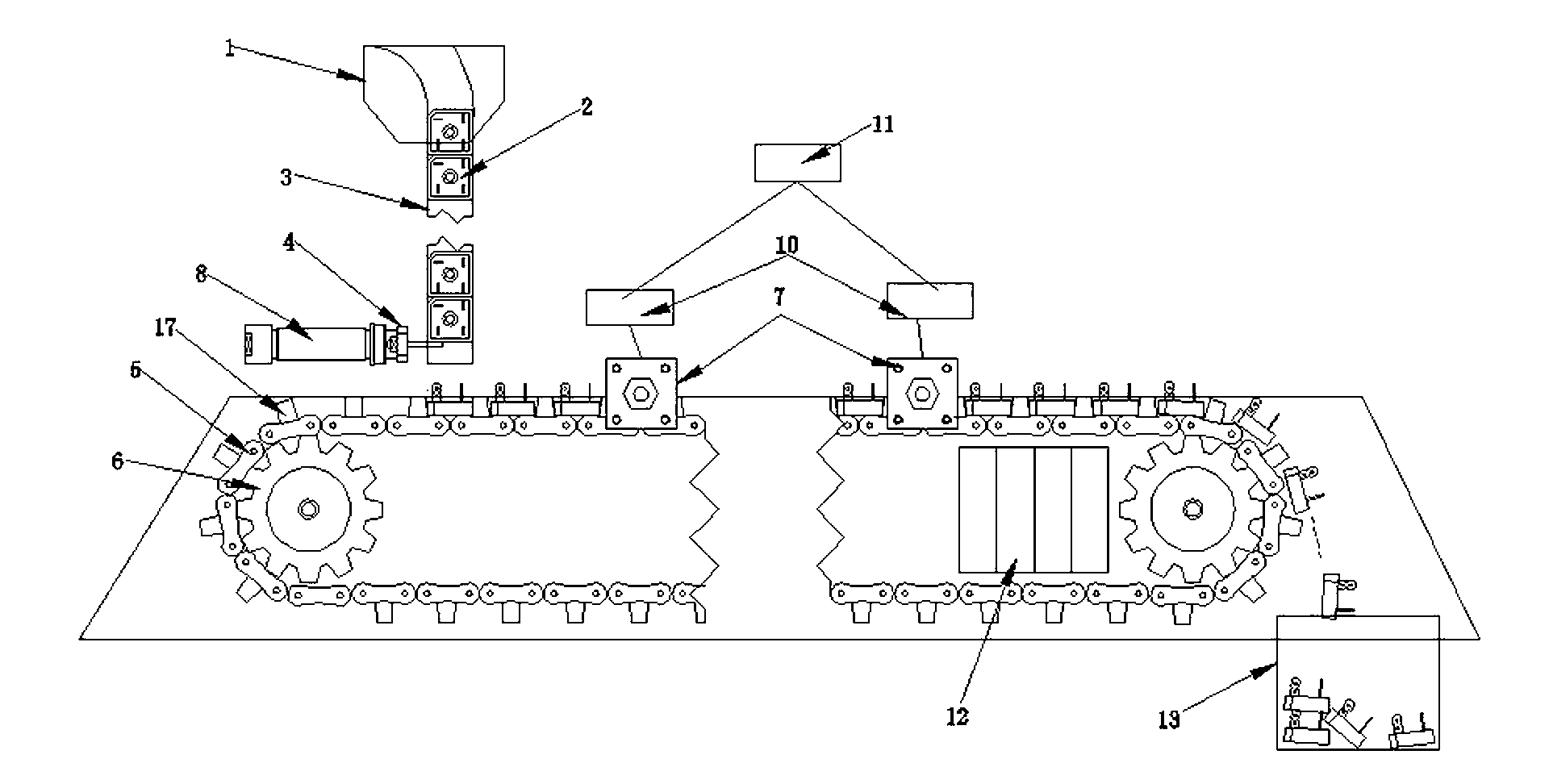

Embodiment 1

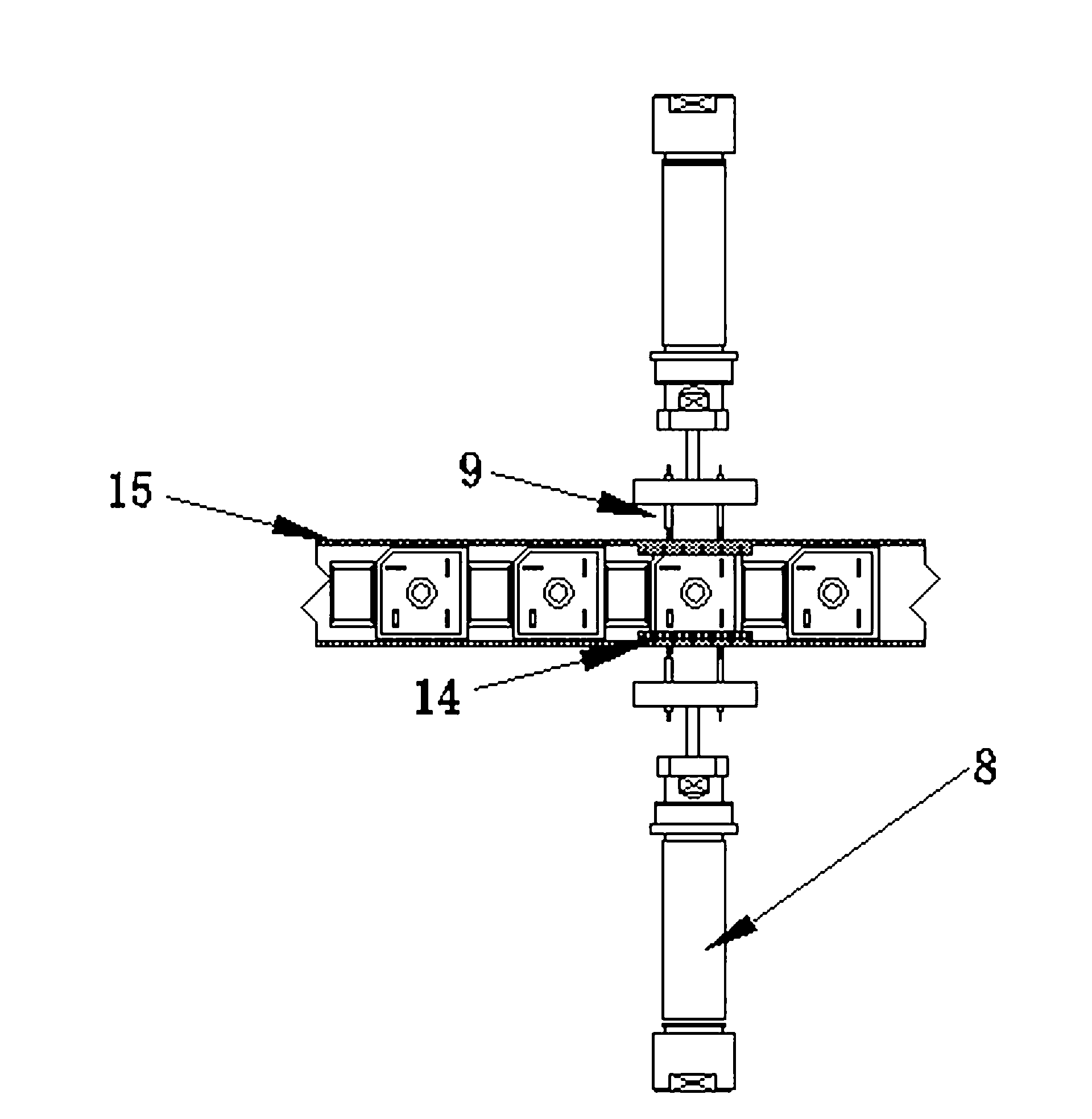

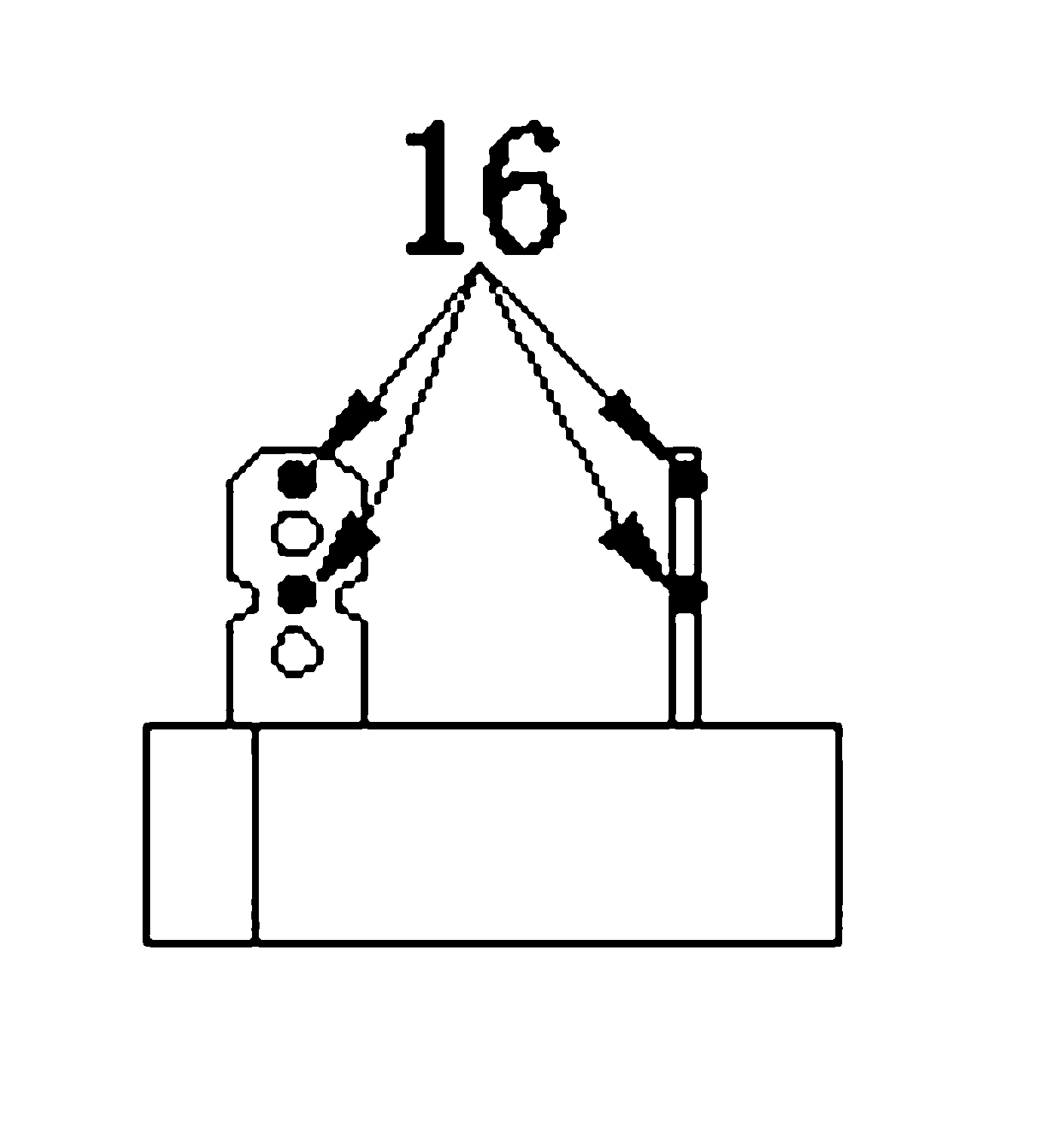

[0039] An automatic testing machine for bridge piles, comprising a test feeding track 5, a stepping motor 6, a feeding mechanism, a data acquisition instrument and a testing mechanism 7, the test feeding track 5 is a ring structure, and is driven by a stepping motor 6 for circulation Rotate, the surface of the test feeding track 5 is provided with a gap arrangement of the limit groove 17, the limit groove 17 matches the shape of the plastic package of the bridge stack 2, and the discharge port of the feeding mechanism corresponds to the limit groove 17 , the testing mechanism 7 includes a primary testing mechanism 7 and a retesting testing mechanism 7, and each set of testing mechanism 7 includes a testing instrument 10, two cylinders 8 and test probes 9, and the two cylinders 8 are set at the limit On both sides of the groove 17, the test probe 9 is fixed on the end of the cylinder piston, and the test probe 9 corresponds to the test point 16 on the pin of the bridge stack 2, ...

Embodiment 2

[0045] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0046] In this embodiment, it is preferable that the limiting groove 17 is formed by a limiting block arranged on the surface of the test feeding track 5 with a gap, and the bottom surface of the limiting groove 17 is parallel to the ground to ensure that the bridge stack 2 is on the testing feeding track 5 Its pins are arranged vertically upward and regularly, which is convenient for testing with the test probe 9 .

[0047] In this embodiment, it is preferable that the limit block is square, but it is not limited to the above arrangement. For example, the limit block can be semicircular or other shapes, so as to test bridge stacks whose plastic bodies are circular or other shapes. 2. Preferably, the limit block is clamped and connected to the test feeding track 5, but it can also be connected by a plug connection or a bolt, so as to facilitate changing the distance betwee...

Embodiment 3

[0050] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0051] In this embodiment, preferably four limit anti-turnover plates 14 are symmetrically arranged on both sides of the test feeding track 5, wherein, every two symmetrical limit and anti-turnover plates 14 correspond to a set of testing mechanism 7, and the position limit The number of anti-overturning plates 14 can be 6, 8 or more, to reserve a place for adding the test mechanism 7 in the future, and to meet the requirements of the second or more tests;

[0052] Further, it is preferable to set a through hole on the limit anti-turnover plate 14, so that the test probe 9 can pass through the through hole to test the pins of the bridge stack 2.

[0053] In this embodiment, preferably, the height of the limiting anti-turnover plate 14 is the same as the length of the pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com